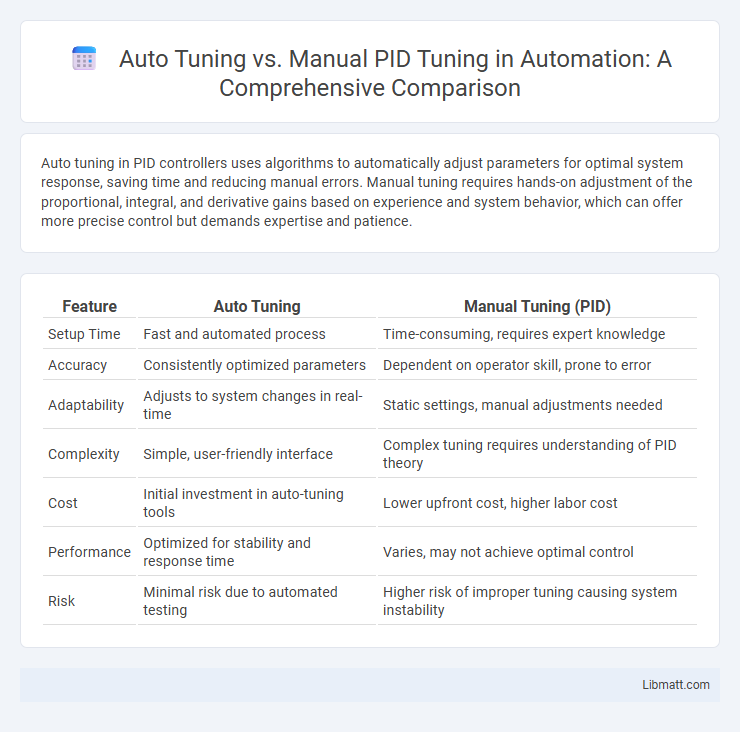

Auto tuning in PID controllers uses algorithms to automatically adjust parameters for optimal system response, saving time and reducing manual errors. Manual tuning requires hands-on adjustment of the proportional, integral, and derivative gains based on experience and system behavior, which can offer more precise control but demands expertise and patience.

Table of Comparison

| Feature | Auto Tuning | Manual Tuning (PID) |

|---|---|---|

| Setup Time | Fast and automated process | Time-consuming, requires expert knowledge |

| Accuracy | Consistently optimized parameters | Dependent on operator skill, prone to error |

| Adaptability | Adjusts to system changes in real-time | Static settings, manual adjustments needed |

| Complexity | Simple, user-friendly interface | Complex tuning requires understanding of PID theory |

| Cost | Initial investment in auto-tuning tools | Lower upfront cost, higher labor cost |

| Performance | Optimized for stability and response time | Varies, may not achieve optimal control |

| Risk | Minimal risk due to automated testing | Higher risk of improper tuning causing system instability |

Introduction to PID Tuning

PID tuning involves adjusting the proportional, integral, and derivative parameters to optimize system control response, minimizing error and enhancing stability. Auto tuning uses algorithms and real-time data analysis to automatically set PID parameters for optimal performance, reducing manual intervention and tuning time. Manual tuning requires expert knowledge to iteratively adjust PID settings based on system behavior, which can be time-consuming and less precise compared to auto tuning methods.

Understanding Auto Tuning in PID Controllers

Auto tuning in PID controllers automatically adjusts the proportional, integral, and derivative parameters to optimize system performance without extensive manual intervention. It leverages system response data to identify the best PID settings, minimizing overshoot and settling time for precise control. Your process efficiency improves as auto tuning adapts to changing conditions faster than manual tuning, reducing downtime and the risk of human error.

Manual Tuning: Fundamentals and Approach

Manual tuning of PID controllers involves adjusting proportional, integral, and derivative gains based on system response to achieve optimal control performance. This approach requires a fundamental understanding of the process dynamics, enabling you to iteratively modify parameters by analyzing overshoot, settling time, and steady-state error. Precise manual tuning offers tailored control but demands significant expertise and time to balance responsiveness and stability effectively.

Key Differences Between Auto and Manual Tuning

Auto tuning of PID controllers uses algorithms to automatically adjust parameters based on system behavior and performance, reducing setup time and minimizing human error. Manual tuning requires your expertise to iteratively modify proportional, integral, and derivative gains, providing fine control but often demanding more time and experience. Key differences include automated parameter optimization in auto tuning versus hands-on, experience-driven adjustments in manual tuning, affecting precision and efficiency in process control.

Advantages of Auto Tuning for PID Systems

Auto tuning for PID systems enhances accuracy by dynamically adjusting parameters to real-time process conditions, reducing the risk of human error inherent in manual tuning. This method significantly saves time and labor by automating the optimization process, enabling faster system stabilization and improved performance. Auto tuning also adapts to process changes or disturbances more efficiently, ensuring consistent control quality and minimizing downtime.

Benefits of Manual Tuning for Custom Applications

Manual tuning of PID controllers offers precise adjustment tailored to the specific dynamics of your custom applications, ensuring optimal performance under unique operating conditions. It enables you to fine-tune parameters based on direct system behavior observations, which can improve stability and reduce overshoot better than generic auto tuning algorithms. This hands-on approach is especially beneficial for complex or nonlinear processes where automated methods may fail to capture nuanced performance requirements.

Common Challenges in Both Tuning Methods

Both auto tuning and manual tuning of PID controllers often face challenges such as system noise, non-linearity, and time delays, which can cause instability or poor performance. You may encounter difficulties in achieving optimal parameter settings due to model inaccuracies or changing process dynamics. Ensuring robust control requires careful handling of these common issues to maintain system efficiency and responsiveness.

Application Scenarios: When to Use Each Method

Auto Tuning excels in complex systems with varying dynamics or when quick, initial parameter adjustments are needed without deep technical expertise. Manual Tuning is preferred in stable, well-understood environments where fine-tuning specific PID parameters based on detailed system knowledge improves performance. Your choice depends on the stability of your process and available expertise, with Auto Tuning offering convenience and Manual Tuning providing precision control.

Impact on System Performance and Stability

Auto tuning enhances system performance by continuously adapting PID parameters, ensuring optimal control and maintaining system stability under varying conditions. Manual tuning relies on fixed parameter settings that may require frequent adjustments to prevent system oscillations or instability, especially in dynamic environments. Your choice between auto and manual tuning significantly affects the precision and responsiveness of the control system, with auto tuning providing more consistent stability and improved performance.

Choosing the Best PID Tuning Method for Your Needs

Selecting the best PID tuning method depends on system complexity, precision requirements, and available time. Auto tuning provides fast, adaptive adjustments ideal for dynamic or unknown systems, while manual tuning offers granular control for fine-tuning specific performance criteria. Evaluating the trade-offs between efficiency and customization helps optimize control loop stability and response.

Auto Tuning vs Manual Tuning (PID) Infographic

libmatt.com

libmatt.com