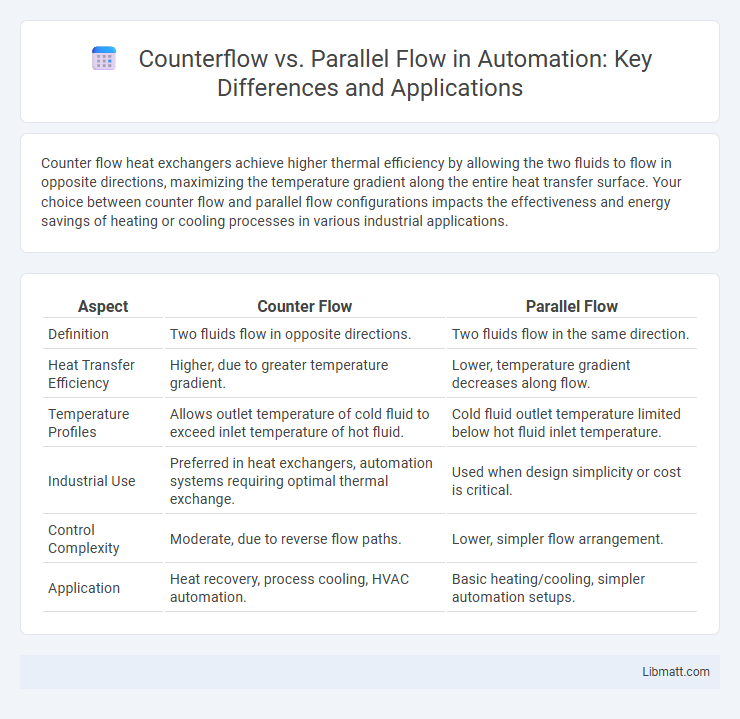

Counter flow heat exchangers achieve higher thermal efficiency by allowing the two fluids to flow in opposite directions, maximizing the temperature gradient along the entire heat transfer surface. Your choice between counter flow and parallel flow configurations impacts the effectiveness and energy savings of heating or cooling processes in various industrial applications.

Table of Comparison

| Aspect | Counter Flow | Parallel Flow |

|---|---|---|

| Definition | Two fluids flow in opposite directions. | Two fluids flow in the same direction. |

| Heat Transfer Efficiency | Higher, due to greater temperature gradient. | Lower, temperature gradient decreases along flow. |

| Temperature Profiles | Allows outlet temperature of cold fluid to exceed inlet temperature of hot fluid. | Cold fluid outlet temperature limited below hot fluid inlet temperature. |

| Industrial Use | Preferred in heat exchangers, automation systems requiring optimal thermal exchange. | Used when design simplicity or cost is critical. |

| Control Complexity | Moderate, due to reverse flow paths. | Lower, simpler flow arrangement. |

| Application | Heat recovery, process cooling, HVAC automation. | Basic heating/cooling, simpler automation setups. |

Introduction to Heat Exchanger Flow Patterns

Counter flow and parallel flow are two primary heat exchanger flow patterns that dictate heat transfer efficiency by the direction of fluid movement. In counter flow, fluids move in opposite directions, maximizing the temperature gradient and enabling greater heat exchange. Parallel flow involves fluids moving in the same direction, which typically results in a lower temperature difference and less efficient heat transfer compared to counter flow designs.

Understanding Counter Flow: Definition and Principles

Counter flow refers to a heat exchange process where two fluids move in opposite directions, allowing maximized temperature gradient along the length of the heat exchanger. This principle enhances heat transfer efficiency by maintaining a higher driving force compared to parallel flow, where fluids move in the same direction. Understanding counter flow helps you optimize thermal systems for improved energy conservation and performance.

Parallel Flow Explained: Basics and Functionality

Parallel flow involves two fluids moving in the same direction, allowing heat to transfer from the hotter fluid to the cooler one along a single path. This arrangement results in a rapid temperature equilibrium between the fluids but generally achieves lower heat transfer efficiency compared to counter flow. The temperature difference decreases steadily along the flow direction, limiting the maximum heat exchange.

Key Differences Between Counter Flow and Parallel Flow

Counter flow heat exchangers transfer heat by having fluids move in opposite directions, maximizing the temperature gradient and improving thermal efficiency. Parallel flow heat exchangers have fluids moving in the same direction, which results in a reduced temperature difference and less efficient heat transfer. The key difference lies in the temperature profiles and heat transfer rates, with counter flow offering higher effectiveness and better performance in applications requiring maximum heat recovery.

Heat Transfer Efficiency: Counter Flow vs Parallel Flow

Counter flow heat exchangers achieve higher heat transfer efficiency compared to parallel flow designs due to the temperature gradient maintained along the entire length of the exchanger, allowing for greater thermal energy exchange. In counter flow, the fluids move in opposite directions, enabling the outlet temperature of the cold fluid to approach the inlet temperature of the hot fluid, maximizing heat recovery. Parallel flow heat exchangers have both fluids moving in the same direction, which limits the temperature difference and results in lower overall heat transfer efficiency.

Temperature Profile Comparison in Both Systems

In counter flow heat exchangers, the temperature gradient between the two fluids remains relatively constant along the length, allowing the outlet temperature of the cold fluid to approach the inlet temperature of the hot fluid, maximizing heat transfer efficiency. Parallel flow systems exhibit a rapidly decreasing temperature difference between the fluids, resulting in lower overall heat transfer and less effective temperature change. Counter flow arrangements are therefore preferred in applications requiring high thermal performance and efficient heat recovery.

Advantages of Counter Flow Heat Exchangers

Counter flow heat exchangers provide superior thermal efficiency by maintaining a larger temperature gradient between the fluids along the entire length of the exchanger, enabling more effective heat transfer. They allow the outlet temperature of the cold fluid to approach or exceed the inlet temperature of the hot fluid, maximizing energy recovery. This design minimizes the required surface area and reduces overall equipment size and cost compared to parallel flow configurations.

Benefits and Limitations of Parallel Flow Design

Parallel flow heat exchangers provide rapid heat transfer with a uniform temperature gradient, making them suitable for applications requiring quick temperature adjustments. However, their design limits the maximum possible temperature difference between fluids, restricting thermal efficiency compared to counter flow systems. They are also more prone to thermal stress due to temperature gradients, potentially shortening equipment lifespan.

Applications and Industry Use Cases

Counter flow heat exchangers are widely used in chemical processing, power plants, and refrigeration systems due to their superior thermal efficiency in transferring heat between fluids moving in opposite directions. Parallel flow configurations, though less efficient, are often found in HVAC systems and automotive radiators where simpler design and lower cost are prioritized. Your choice between counter flow and parallel flow depends on specific industry requirements for heat transfer performance and system complexity.

Choosing the Right Flow Pattern: Factors to Consider

Choosing the right flow pattern between counter flow and parallel flow depends on factors such as heat transfer efficiency, temperature gradient, and system design constraints. Counter flow offers higher thermal efficiency by maintaining a greater temperature difference along the heat exchanger, making it ideal for applications requiring maximum heat recovery. Parallel flow may be chosen for simpler design and lower initial costs, but it compromises on temperature change and overall efficiency.

Counter Flow vs Parallel Flow Infographic

libmatt.com

libmatt.com