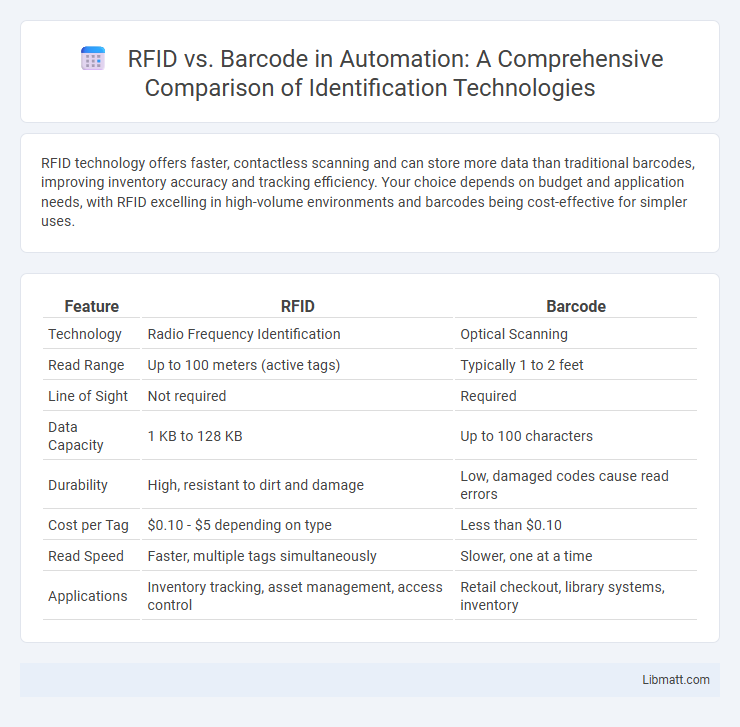

RFID technology offers faster, contactless scanning and can store more data than traditional barcodes, improving inventory accuracy and tracking efficiency. Your choice depends on budget and application needs, with RFID excelling in high-volume environments and barcodes being cost-effective for simpler uses.

Table of Comparison

| Feature | RFID | Barcode |

|---|---|---|

| Technology | Radio Frequency Identification | Optical Scanning |

| Read Range | Up to 100 meters (active tags) | Typically 1 to 2 feet |

| Line of Sight | Not required | Required |

| Data Capacity | 1 KB to 128 KB | Up to 100 characters |

| Durability | High, resistant to dirt and damage | Low, damaged codes cause read errors |

| Cost per Tag | $0.10 - $5 depending on type | Less than $0.10 |

| Read Speed | Faster, multiple tags simultaneously | Slower, one at a time |

| Applications | Inventory tracking, asset management, access control | Retail checkout, library systems, inventory |

Introduction to RFID and Barcode Technologies

RFID (Radio Frequency Identification) technology uses radio waves to automatically identify and track tags attached to objects, enabling non-line-of-sight scanning and faster data retrieval. Barcode technology relies on optical scanning to read printed codes representing data, requiring direct line-of-sight and slower processing speeds. Both technologies are widely used in inventory management, but RFID offers greater efficiency and enhanced data capacity compared to traditional barcodes.

How RFID Works: A Brief Overview

RFID (Radio Frequency Identification) uses electromagnetic fields to automatically identify and track tags attached to objects, enabling wireless data transmission between the RFID reader and tag. Unlike barcodes, which require direct line-of-sight scanning, RFID tags can be read at varying distances and through multiple materials, improving efficiency in inventory management and asset tracking. The system consists of three main components: RFID tags (embedded with microchips and antennas), readers (to emit and receive signals), and data processing software to interpret and manage the captured information.

Understanding Barcode Systems

Barcode systems rely on optical scanning to read encoded data represented by varying widths and spacings of parallel lines, making them cost-effective and widely adopted for inventory management and point-of-sale applications. Unlike RFID, barcodes require direct line-of-sight scanning and are typically limited to identifying individual items one at a time. Your choice between RFID and barcode solutions should consider factors such as scanning range, speed, and environmental conditions where data capture occurs.

Key Differences Between RFID and Barcodes

RFID uses radio waves to automatically identify and track tags attached to objects, allowing multiple items to be scanned simultaneously without line of sight, while barcodes require visual scanning one at a time. RFID tags are more durable and can store larger amounts of data compared to barcodes, which are susceptible to damage and offer limited information. Your choice between RFID and barcode technology depends on factors like inventory speed, cost, and environmental conditions.

Accuracy and Data Reliability Comparison

RFID technology offers higher accuracy and data reliability compared to barcodes by enabling non-line-of-sight scanning and simultaneous reading of multiple tags, reducing human error and data loss. Barcodes require direct line-of-sight and manual scanning, which increases the risk of misreads and incomplete data capture. Your operations can benefit from RFID's enhanced precision and real-time data updates, leading to improved inventory management and reduced discrepancies.

Speed and Efficiency: RFID vs Barcode

RFID technology enables rapid data capture without direct line-of-sight, processing multiple tags simultaneously, significantly outperforming barcode scanners that require individual scans. Inventory management using RFID reduces time by up to 75%, enhancing operational efficiency in supply chains and retail environments. Barcode systems, while cost-effective, involve manual scanning that can slow down workflows and increase the risk of human error.

Cost Implications: Initial Investment and Maintenance

RFID systems generally require a higher initial investment due to the cost of RFID tags and readers, which can range from $0.10 to $5 per tag and $500 to $2,000 per reader, compared to barcode labels costing just a few cents and barcode scanners priced between $100 and $500. Maintenance costs for RFID include occasional software updates and hardware calibration, whereas barcode systems incur minimal maintenance primarily related to label replacement and scanner upkeep. Over time, RFID's higher upfront and maintenance expenses can be offset by improved inventory accuracy and labor savings, influencing total cost of ownership decisions.

Industry Applications: When to Use RFID or Barcode

RFID technology excels in industries requiring rapid, hands-free, and bulk data capture such as retail inventory management, supply chain logistics, and asset tracking in healthcare. Barcodes remain ideal for cost-sensitive applications with lower volumes, like small retail stores, libraries, and simple point-of-sale labeling. Choosing RFID over barcodes is optimal when real-time tracking, durability in harsh environments, and multi-item scanning enhance operational efficiency.

Security and Data Integrity Considerations

RFID technology offers enhanced security features compared to traditional barcodes, including encryption and password protection that help safeguard data from unauthorized access. Barcodes are more vulnerable to replication and damage, which can compromise data integrity and lead to errors during scanning. You can improve your asset tracking and inventory management by choosing RFID for its superior protection against tampering and data loss.

Future Trends in Identification Technologies

RFID technology is expected to dominate future identification systems due to its ability to read multiple tags simultaneously without line-of-sight, enabling faster and more accurate inventory management. Emerging trends point to the integration of RFID with IoT devices and blockchain for enhanced security and real-time tracking across supply chains. While barcodes remain cost-effective and widely used, innovations like QR codes and smart labels are evolving to complement or gradually replace traditional optical scanning methods.

RFID vs Barcode Infographic

libmatt.com

libmatt.com