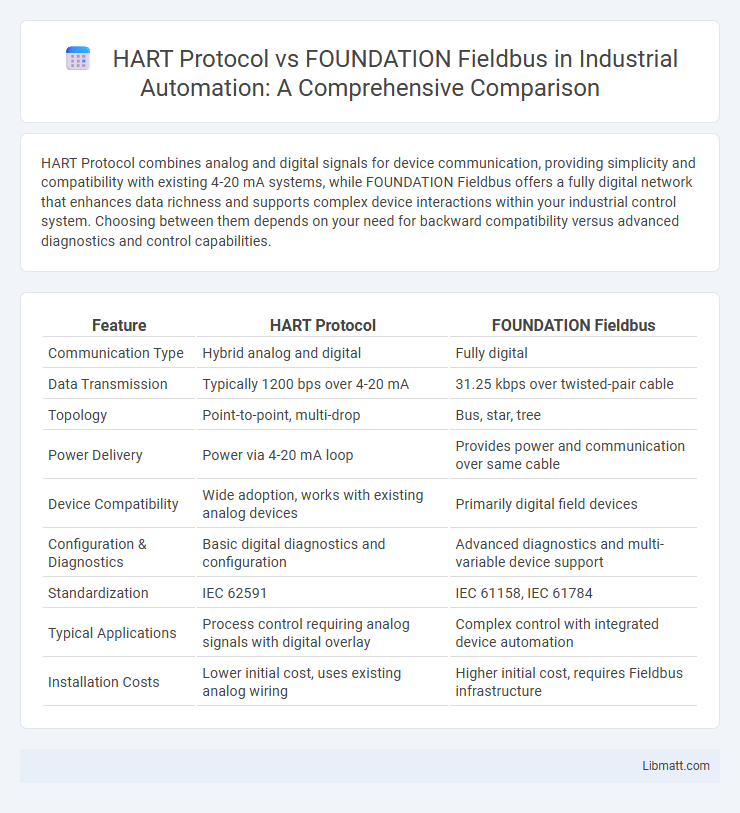

HART Protocol combines analog and digital signals for device communication, providing simplicity and compatibility with existing 4-20 mA systems, while FOUNDATION Fieldbus offers a fully digital network that enhances data richness and supports complex device interactions within your industrial control system. Choosing between them depends on your need for backward compatibility versus advanced diagnostics and control capabilities.

Table of Comparison

| Feature | HART Protocol | FOUNDATION Fieldbus |

|---|---|---|

| Communication Type | Hybrid analog and digital | Fully digital |

| Data Transmission | Typically 1200 bps over 4-20 mA | 31.25 kbps over twisted-pair cable |

| Topology | Point-to-point, multi-drop | Bus, star, tree |

| Power Delivery | Power via 4-20 mA loop | Provides power and communication over same cable |

| Device Compatibility | Wide adoption, works with existing analog devices | Primarily digital field devices |

| Configuration & Diagnostics | Basic digital diagnostics and configuration | Advanced diagnostics and multi-variable device support |

| Standardization | IEC 62591 | IEC 61158, IEC 61784 |

| Typical Applications | Process control requiring analog signals with digital overlay | Complex control with integrated device automation |

| Installation Costs | Lower initial cost, uses existing analog wiring | Higher initial cost, requires Fieldbus infrastructure |

Introduction to HART Protocol and FOUNDATION Fieldbus

HART Protocol is a hybrid communication system combining analog and digital signals, widely used for device-level communication in industrial automation. FOUNDATION Fieldbus is a fully digital, high-speed communication network enabling real-time control and diagnostics among field devices in complex process environments. Understanding these protocols helps optimize Your industrial communication infrastructure for efficiency and interoperability.

Historical Background and Evolution

HART Protocol emerged in the 1980s as a hybrid analog and digital communication standard designed to enhance traditional 4-20 mA field signals with digital data, facilitating easier device diagnostics and configuration without disrupting process control. FOUNDATION Fieldbus was developed in the late 1980s and early 1990s as a fully digital, two-way communication protocol aiming to replace analog signals entirely, enabling complex control functions directly in field devices and supporting integrated asset management. Both protocols have evolved over decades, with HART expanding into wireless capabilities through WirelessHART and FOUNDATION Fieldbus advancing toward enhanced interoperability and integration in modern industrial automation systems.

Architecture Overview

HART Protocol operates on a hybrid analog and digital communication architecture, allowing digital signals to be superimposed on traditional 4-20 mA analog wiring, facilitating backward compatibility and easy integration into existing systems. FOUNDATION Fieldbus uses a fully digital, bus-based architecture that supports multiple devices communicating over a single pair of wires, enabling advanced distributed control and diagnostics with real-time data exchange. The FOUNDATION Fieldbus architecture supports segment-based power and communication, while HART's point-to-point or multidrop configurations focus on simplicity and widespread device compatibility.

Communication Principles

HART Protocol utilizes a hybrid communication method combining analog signals with digital communication over the same wiring, enabling device diagnostics and configuration without interrupting the 4-20 mA signal. FOUNDATION Fieldbus operates on a fully digital, bi-directional communication system that allows multiple devices to communicate simultaneously over a shared network, facilitating advanced process control and real-time data exchange. The fundamental difference lies in HART's overlay on traditional analog signals versus FOUNDATION Fieldbus's purely digital, network-based communication architecture.

Device Integration and Compatibility

HART Protocol excels in device integration due to its widespread compatibility with analog systems and easy retrofit capability, supporting over 40 million installed devices worldwide. FOUNDATION Fieldbus offers a more advanced digital communication platform enabling seamless integration of multiple devices on a single network, enhancing data richness and real-time control capabilities. While HART ensures interoperability across various manufacturers' devices, FOUNDATION Fieldbus provides standardized profiles for complex instruments, optimizing system diagnostics and performance monitoring.

Installation and Wiring Requirements

HART Protocol installation typically requires standard 4-20mA wiring with a superimposed digital signal, making it compatible with existing analog infrastructure and simpler to retrofit. FOUNDATION Fieldbus demands a more complex installation with specialized twisted-pair cabling that carries both power and digital communication, enabling multiple devices to share a single bus segment for advanced control. Your choice depends on the complexity of your system and whether you prefer leveraging existing wiring or implementing a fully digital network with integrated wiring needs.

Data Transmission Speed and Capacity

HART Protocol operates at a lower data transmission speed of 1200 bits per second, suitable for simple point-to-point communication with limited data capacity. FOUNDATION Fieldbus supports much higher speeds up to 31.25 kbps, enabling complex multi-device networks with extensive data throughput and real-time control capabilities. This higher speed and capacity make FOUNDATION Fieldbus ideal for advanced process automation requiring robust data exchange.

Diagnostic and Maintenance Capabilities

HART Protocol offers enhanced diagnostic and maintenance capabilities through its ability to transmit both analog and digital signals, enabling real-time device diagnostics and predictive maintenance. FOUNDATION Fieldbus provides comprehensive diagnostics at the field device level with continuous, bi-directional digital communication, allowing detailed device health monitoring and efficient asset management. Both protocols improve operational reliability, but FOUNDATION Fieldbus excels in complex system environments with integrated advanced diagnostics.

Industry Applications and Use Cases

HART Protocol is widely used in process industries such as oil and gas, chemical manufacturing, and water treatment due to its compatibility with traditional 4-20 mA analog signals, enabling seamless integration in existing control systems. FOUNDATION Fieldbus excels in complex and large-scale automation projects like power plants and pharmaceuticals, offering advanced digital communication capabilities for improved diagnostics and device interoperability. Your choice depends on the need for backward compatibility with analog devices (favoring HART) or sophisticated control and real-time data exchange (favoring FOUNDATION Fieldbus).

Future Trends and Technology Outlook

HART Protocol continues evolving with enhancements in wireless HART and integration with IoT platforms, supporting broader digital transformation in industrial automation. FOUNDATION Fieldbus drives the development of fully digital, device-level networking that facilitates real-time diagnostics and advanced asset management for Industry 4.0 environments. Both protocols are converging towards hybrid solutions combining robust field-level communication with cloud connectivity to improve predictive maintenance and operational efficiency.

HART Protocol vs FOUNDATION Fieldbus Infographic

libmatt.com

libmatt.com