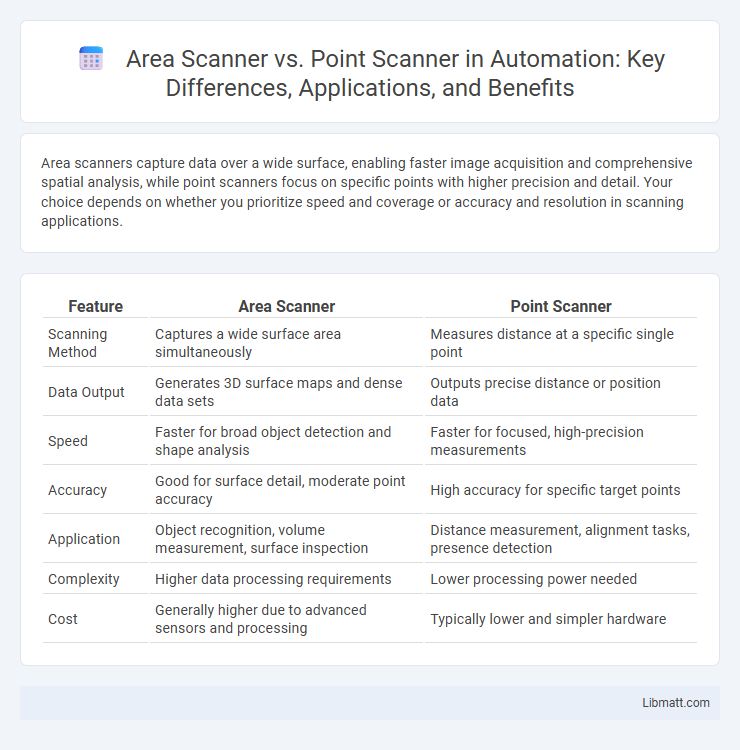

Area scanners capture data over a wide surface, enabling faster image acquisition and comprehensive spatial analysis, while point scanners focus on specific points with higher precision and detail. Your choice depends on whether you prioritize speed and coverage or accuracy and resolution in scanning applications.

Table of Comparison

| Feature | Area Scanner | Point Scanner |

|---|---|---|

| Scanning Method | Captures a wide surface area simultaneously | Measures distance at a specific single point |

| Data Output | Generates 3D surface maps and dense data sets | Outputs precise distance or position data |

| Speed | Faster for broad object detection and shape analysis | Faster for focused, high-precision measurements |

| Accuracy | Good for surface detail, moderate point accuracy | High accuracy for specific target points |

| Application | Object recognition, volume measurement, surface inspection | Distance measurement, alignment tasks, presence detection |

| Complexity | Higher data processing requirements | Lower processing power needed |

| Cost | Generally higher due to advanced sensors and processing | Typically lower and simpler hardware |

Introduction to Area Scanners and Point Scanners

Area scanners capture two-dimensional images by simultaneously scanning a broad surface, making them ideal for applications requiring comprehensive spatial information and rapid data acquisition. Point scanners analyze single points sequentially with laser or sensor beams, offering high precision and depth measurement typically used in detailed 3D modeling and surface profiling. Both technologies serve distinct roles in industries like manufacturing, robotics, and autonomous vehicles, depending on the needed balance between scanning speed and resolution accuracy.

Overview of Scanning Technologies

Area scanners capture entire surfaces simultaneously by utilizing an array of sensors or cameras, enabling rapid, high-resolution imaging suitable for complex object analysis. Point scanners, equipped with a single laser or sensor, sequentially measure data points, delivering precise depth information ideal for detailed surface profiling. Both technologies serve distinct purposes in 3D scanning, where area scanners excel in speed and coverage, while point scanners offer superior accuracy and resolution.

How Area Scanners Work

Area scanners capture three-dimensional images by projecting a structured light pattern onto a surface and using cameras to record the deformation of this pattern, enabling the creation of detailed 3D models. These scanners operate by illuminating entire regions simultaneously, allowing for rapid data acquisition over large surfaces. The high-resolution imaging and ability to capture complex geometries make area scanners ideal for applications requiring comprehensive surface analysis.

How Point Scanners Operate

Point scanners operate by directing a focused laser beam across a surface, capturing spatial data point by point to create precise three-dimensional measurements. These scanners utilize high-frequency laser pulses combined with time-of-flight or phase-shift technologies to measure distances accurately. The resulting data provides detailed depth and positioning information, ideal for applications requiring high spatial resolution.

Key Differences: Area Scanner vs Point Scanner

Area scanners capture entire surfaces simultaneously by projecting a grid or pattern of light, enabling rapid 3D imaging ideal for large object inspection. Point scanners measure distance one point at a time using laser beams, offering higher precision suitable for detailed analysis of small or complex objects. The key difference lies in speed versus resolution: area scanners excel in speed and comprehensive coverage, while point scanners provide superior accuracy and finer detail.

Accuracy and Resolution Comparison

Area scanners capture entire surfaces at once, providing high-resolution images with consistent accuracy across broad regions, ideal for complex object scanning. Point scanners measure individual points sequentially, offering precise depth data with potentially higher accuracy for detailed, small-scale features but slower data acquisition. Your choice depends on whether you prioritize fast, high-resolution surface mapping or meticulous point-by-point measurement accuracy.

Application Areas: Where Each Scanner Excels

Area scanners excel in applications requiring high-speed scanning of large surfaces, such as industrial quality control, 3D modeling, and medical imaging, where capturing comprehensive spatial data is essential. Point scanners are preferred in precision-focused tasks like metrology, robotics, and detailed object inspection, where accuracy in pinpoint measurements is critical. Your choice depends on whether you prioritize comprehensive area data or pinpoint accuracy for your specific scanning needs.

Speed and Efficiency Analysis

Area scanners capture a wide field of view in a single scan, significantly increasing speed and efficiency for large-scale or complex surfaces, while point scanners focus on individual points, offering higher precision but slower data acquisition. The parallel processing capability of area scanners reduces scanning time and is ideal for applications requiring rapid data collection across broad areas. Conversely, point scanners excel in detail-sensitive tasks where accuracy outweighs speed, making each suitable for specific industrial or research needs based on efficiency and throughput requirements.

Cost Implications and ROI

Area scanners generally involve higher upfront costs due to their advanced technology and larger coverage, but they provide better efficiency and faster data acquisition, leading to improved ROI in large-scale projects. Point scanners are more affordable initially but may require longer scanning times and additional labor, potentially increasing operational costs and reducing overall ROI for extensive applications. Choosing between the two depends on project scale, budget constraints, and desired accuracy, with area scanners offering more cost-effective returns in large or complex scanning tasks.

Choosing the Right Scanner for Your Needs

When choosing the right scanner for your needs, consider that area scanners capture entire surfaces quickly, making them ideal for detailed 3D models of complex objects or environments. Point scanners, on the other hand, provide high precision by measuring individual points, perfect for applications requiring exact measurements such as industrial inspection or engineering. Evaluate factors like scanning speed, resolution, object size, and accuracy requirements to select the optimal technology for your project.

Area Scanner vs Point Scanner Infographic

libmatt.com

libmatt.com