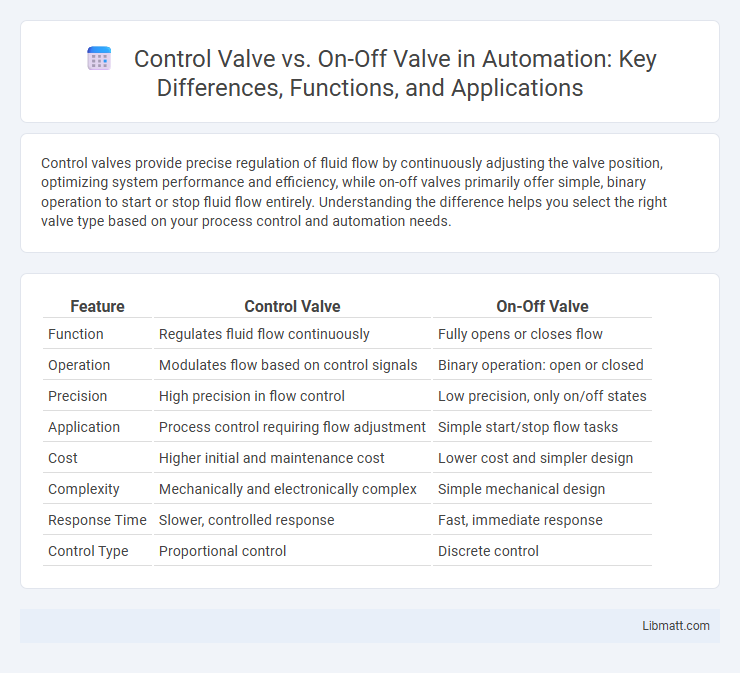

Control valves provide precise regulation of fluid flow by continuously adjusting the valve position, optimizing system performance and efficiency, while on-off valves primarily offer simple, binary operation to start or stop fluid flow entirely. Understanding the difference helps you select the right valve type based on your process control and automation needs.

Table of Comparison

| Feature | Control Valve | On-Off Valve |

|---|---|---|

| Function | Regulates fluid flow continuously | Fully opens or closes flow |

| Operation | Modulates flow based on control signals | Binary operation: open or closed |

| Precision | High precision in flow control | Low precision, only on/off states |

| Application | Process control requiring flow adjustment | Simple start/stop flow tasks |

| Cost | Higher initial and maintenance cost | Lower cost and simpler design |

| Complexity | Mechanically and electronically complex | Simple mechanical design |

| Response Time | Slower, controlled response | Fast, immediate response |

| Control Type | Proportional control | Discrete control |

Introduction to Control Valves and On-Off Valves

Control valves regulate fluid flow by continuously adjusting the valve position to maintain desired process variables such as pressure, temperature, or flow rate. On-off valves operate in two distinct states--fully open or fully closed--making them ideal for simple operation systems requiring binary control. Understanding the functional differences assists in selecting appropriate valves for applications needing precise modulation versus basic start-stop control.

Key Differences Between Control Valve and On-Off Valve

Control valves regulate fluid flow continuously to maintain precise process control, while on-off valves operate only in fully open or fully closed positions for simple flow start or stop functions. Control valves use actuators and positioners to modulate flow based on real-time feedback, whereas on-off valves rely on manual or basic automated operation without intermediate flow adjustment. Your choice depends on whether you need fine control and process stability (control valve) or straightforward isolation and flow interruption (on-off valve).

Functions and Applications of Control Valves

Control valves regulate fluid flow rate, pressure, and temperature by continuously modulating the valve opening to maintain precise process control in industries such as chemical manufacturing, power generation, and water treatment. On-off valves primarily function to start or stop fluid flow without intermediate flow control, typically used in simple isolation or emergency shut-off applications. Your choice of a control valve ensures optimal process efficiency and safety where variable flow regulation is critical.

Functions and Uses of On-Off Valves

On-off valves primarily function to start or stop the flow of fluids in a pipeline, providing straightforward open or closed positions without intermediate flow control. These valves are widely used in process industries for isolating equipment, emergency shut-off situations, and straightforward flow regulation where precise modulation is unnecessary. Common applications include water treatment, chemical processing, and HVAC systems where ensuring a reliable seal and quick actuation are critical.

Design and Construction Comparison

Control valves feature a complex design with a modulating mechanism that adjusts flow rate continuously, incorporating components such as a plug, seat, and actuator for precise regulation. On-off valves utilize a simpler construction, often employing a ball, gate, or butterfly mechanism that allows only fully open or closed positions for straightforward flow control. Your choice hinges on the need for finely tuned flow variation found in control valves versus the binary operation efficiency of on-off valves.

Performance and Precision in Fluid Control

Control valves provide superior performance and precision in fluid control by enabling continuous modulation of flow rates, pressure, and temperature, ensuring exact process parameters are maintained. On-off valves operate in a binary manner, fully open or closed, which limits their ability to fine-tune flow, making them less suitable for applications requiring accurate adjustments. You benefit from enhanced system efficiency and reduced energy consumption when using control valves for precise fluid management.

Automation and Integration Capabilities

Control valves offer advanced automation and integration capabilities by enabling precise modulation of fluid flow, pressure, or temperature through continuous control signals, often compatible with DCS, PLC, and SCADA systems. On-off valves provide basic automation by functioning as binary devices, opening or closing fully with simple actuator mechanisms, making them suitable for straightforward system integrations. The enhanced feedback and diagnostic features in control valves support predictive maintenance and process optimization, while on-off valves generally lack such comprehensive communication and monitoring capabilities.

Cost Considerations and Maintenance Requirements

Control valves generally cost more upfront due to their complex design and precise flow regulation capabilities, whereas on-off valves are typically more affordable and simpler in construction. Maintenance for control valves involves regular calibration and inspection to ensure accurate performance, while on-off valves require less frequent upkeep, mainly focusing on checking seals and straightforward mechanical parts. Understanding your system's needs will help determine which valve offers the best balance between cost efficiency and maintenance demands.

Industry-Specific Applications and Case Studies

Control valves are essential in industries requiring precise flow regulation, such as chemical processing and power generation, where maintaining optimal process conditions is critical. On-off valves find widespread use in sectors like water treatment and HVAC systems for simple start-stop operations, ensuring safety and operational efficiency. Case studies in oil and gas demonstrate control valves optimizing refining processes, while manufacturing plants utilize on-off valves for emergency shutdowns and maintenance isolation.

Choosing the Right Valve: Control vs On-Off

Choosing the right valve depends on the specific requirements of your application, with control valves offering precise flow regulation and on-off valves providing simple open/close functions. Control valves, such as globe or ball valves with actuators, enable continuous modulation of flow rates, ideal for processes requiring accurate pressure or temperature control. On-off valves, like gate or butterfly valves, are best suited for applications demanding quick shutoff or isolation, where flow is either fully allowed or completely stopped.

Control Valve vs On-Off Valve Infographic

libmatt.com

libmatt.com