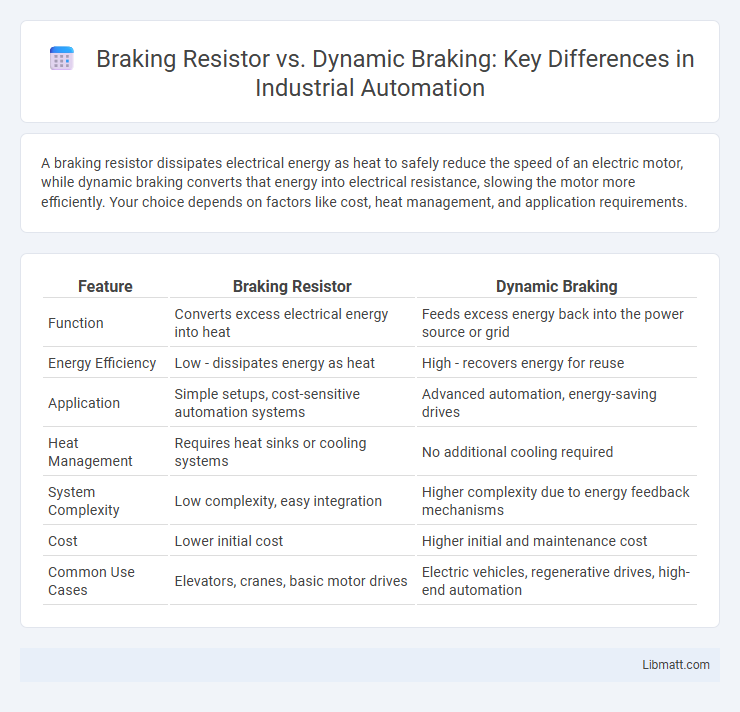

A braking resistor dissipates electrical energy as heat to safely reduce the speed of an electric motor, while dynamic braking converts that energy into electrical resistance, slowing the motor more efficiently. Your choice depends on factors like cost, heat management, and application requirements.

Table of Comparison

| Feature | Braking Resistor | Dynamic Braking |

|---|---|---|

| Function | Converts excess electrical energy into heat | Feeds excess energy back into the power source or grid |

| Energy Efficiency | Low - dissipates energy as heat | High - recovers energy for reuse |

| Application | Simple setups, cost-sensitive automation systems | Advanced automation, energy-saving drives |

| Heat Management | Requires heat sinks or cooling systems | No additional cooling required |

| System Complexity | Low complexity, easy integration | Higher complexity due to energy feedback mechanisms |

| Cost | Lower initial cost | Higher initial and maintenance cost |

| Common Use Cases | Elevators, cranes, basic motor drives | Electric vehicles, regenerative drives, high-end automation |

Introduction to Braking Resistor and Dynamic Braking

Braking resistors are specialized electrical components designed to dissipate excess energy generated during the deceleration of electric motors, converting kinetic energy into heat to prevent system overloads. Dynamic braking involves using these resistors to safely absorb the regenerative energy when a motor slows down, enhancing control and protecting drive components. Understanding how braking resistors function within dynamic braking systems helps optimize your motor control performance and ensure equipment longevity.

What is a Braking Resistor?

A braking resistor is an electrical component designed to dissipate excess energy generated during the deceleration of electric motors, converting kinetic energy into heat. It plays a critical role in dynamic braking systems by providing a controlled path for electrical current, preventing damage to the motor or drive. Your system relies on braking resistors to safely manage energy and improve overall braking performance.

What is Dynamic Braking?

Dynamic braking is a method used to slow down electric motors by converting kinetic energy into electrical energy, which is then dissipated as heat through a resistor. A braking resistor plays a crucial role in this process by safely handling and dissipating the excess energy to prevent damage to the motor and drive system. Understanding dynamic braking helps you choose the right braking resistor to enhance motor control and protect your equipment effectively.

Key Differences Between Braking Resistor and Dynamic Braking

Braking resistors dissipate kinetic energy as heat through a resistor during motor deceleration, whereas dynamic braking involves using the motor as a generator to convert kinetic energy into electrical energy, often routed back to the power supply or resistor. Braking resistors are simpler and cost-effective for low-power applications, while dynamic braking systems provide more efficient energy recovery in high-power industrial settings. The main difference lies in energy dissipation methods: resistors absorb energy as heat, versus dynamic braking's potential for energy regeneration or controlled dissipation.

Applications of Braking Resistors

Braking resistors are primarily used in industrial applications where they dissipate excess energy generated during the braking phase of electric motors, preventing damage to the drive system. These resistors are essential in conveyor systems, elevators, and cranes where rapid or frequent stops occur, allowing for precise speed control and enhanced safety. Using a braking resistor ensures your machinery operates efficiently by converting kinetic energy into heat, reducing wear on mechanical components.

Applications of Dynamic Braking

Dynamic braking is commonly used in electric trains, cranes, and elevators where rapid and controlled deceleration is essential to ensure safety and equipment longevity. This braking method converts kinetic energy into heat via braking resistors, effectively dissipating energy without mechanical wear. Your systems benefit from dynamic braking in high-inertia loads and frequent stop-start operations, enhancing operational efficiency and reducing maintenance costs.

Advantages of Braking Resistors

Braking resistors provide efficient energy dissipation during motor deceleration by converting excess electrical energy into heat, preventing damage to drive components and extending equipment lifespan. Their simple design requires minimal maintenance and offers precise control over braking torque, improving system reliability. You benefit from enhanced safety and reduced downtime, making braking resistors ideal for high-performance industrial applications.

Benefits of Dynamic Braking

Dynamic braking offers significant energy savings by converting kinetic energy into electrical energy, which is dissipated as heat through braking resistors, reducing wear on mechanical brake components and extending their lifespan. This method enhances system reliability and safety by providing precise and responsive braking control, essential in high-speed or heavy-duty applications such as electric trains and industrial machinery. Dynamic braking also improves overall efficiency by minimizing downtime and maintenance costs compared to traditional friction braking systems.

Factors to Consider When Choosing Between Braking Resistor and Dynamic Braking

When choosing between a braking resistor and dynamic braking, key factors to consider include the power dissipation capacity, system compatibility, and cost efficiency. Braking resistors provide controlled energy dissipation as heat, suitable for applications with limited regenerative capabilities, while dynamic braking converts kinetic energy into electrical energy fed back into the power supply, ideal for energy recovery systems. Assessing system load cycles, heat management requirements, and energy recovery potential ensures optimal braking performance and operational cost savings.

Conclusion: Best Practices for Effective Motor Braking

Effective motor braking requires selecting the appropriate method based on application needs, where braking resistors offer controlled energy dissipation through resistive loads, enhancing safety and performance in dynamic braking systems. Dynamic braking integrates braking resistors with motor control to convert kinetic energy into heat, providing precise deceleration and reducing mechanical wear. Utilizing braking resistors within dynamic braking systems ensures optimal energy management, extended motor lifespan, and improved overall braking efficiency in industrial applications.

Braking Resistor vs Dynamic Braking Infographic

libmatt.com

libmatt.com