Quick disconnect connections offer easy installation and removal, making them ideal for applications requiring frequent maintenance or component swaps. Hardwired connections provide a more secure and reliable electrical connection, enhancing safety and performance in permanent setups.

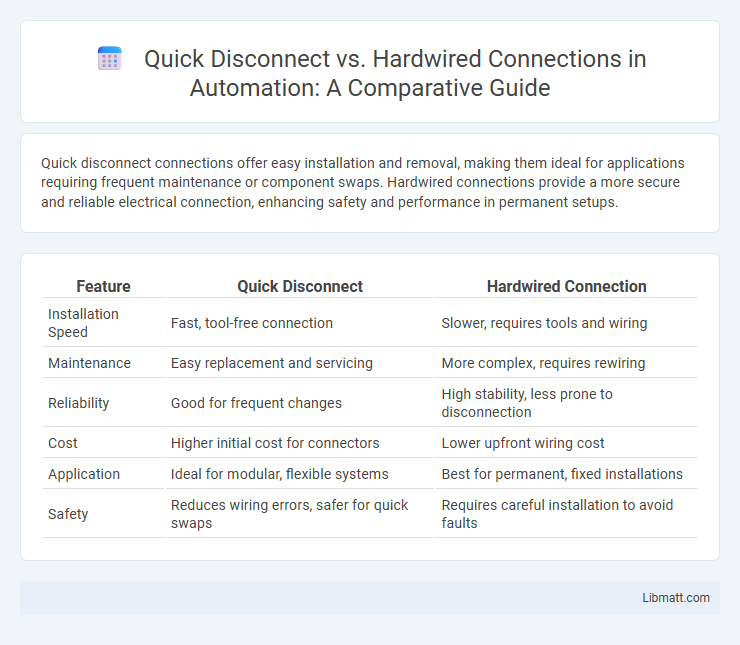

Table of Comparison

| Feature | Quick Disconnect | Hardwired Connection |

|---|---|---|

| Installation Speed | Fast, tool-free connection | Slower, requires tools and wiring |

| Maintenance | Easy replacement and servicing | More complex, requires rewiring |

| Reliability | Good for frequent changes | High stability, less prone to disconnection |

| Cost | Higher initial cost for connectors | Lower upfront wiring cost |

| Application | Ideal for modular, flexible systems | Best for permanent, fixed installations |

| Safety | Reduces wiring errors, safer for quick swaps | Requires careful installation to avoid faults |

Introduction to Quick Disconnect and Hardwired Connections

Quick disconnect connections enable fast, tool-free detachment of electrical components, enhancing convenience and minimizing downtime in various applications. Hardwired connections provide a permanent, secure electrical link by directly joining wires, ensuring maximum reliability and consistent power delivery. Your choice depends on the need for flexibility versus durability in your electrical system design.

Defining Quick Disconnect Connections

Quick disconnect connections are electrical connectors designed for rapid and easy separation without tools, enhancing convenience and maintenance efficiency. These connectors typically feature standardized plugs and sockets that ensure secure electrical contact while allowing swift detachment. Your choice between quick disconnect and hardwired connection depends on the need for flexibility versus permanent, robust wiring solutions.

What Are Hardwired Connections?

Hardwired connections involve directly connecting devices using permanent wiring, typically secured inside walls or electrical boxes for safety and reliability. These connections provide stable power or data transmission with minimal interference, commonly used in home security systems, lighting fixtures, and HVAC controls. Compared to quick disconnects, hardwired setups offer enhanced durability and consistent performance but require professional installation and are less flexible for frequent changes.

Key Differences Between Quick Disconnect and Hardwired

Quick disconnect connections allow rapid detachment without tools, enhancing maintenance efficiency and reducing downtime in electrical systems. Hardwired connections involve permanent wiring, providing superior durability and consistent conductivity but complicating repairs and modifications. Key differences include ease of installation and replacement, mechanical stability, and suitability for applications demanding frequent disconnection versus long-term reliability.

Installation Process Compared

Quick disconnect installations require minimal tools and can be completed rapidly by snapping connectors into place, making them ideal for temporary or modular setups. Hardwired connections involve stripping wires, securing them with screws or soldering, and typically require an electrician or skilled technician, resulting in a longer and more complex installation process. The ease and speed of quick disconnects reduce labor costs and downtime compared to the permanent and more secure nature of hardwired connections.

Reliability and Performance Analysis

Quick disconnect connectors offer ease of maintenance and faster replacement times but may introduce slight resistance variability affecting signal integrity, potentially impacting performance in high-frequency applications. Hardwired connections ensure consistent electrical conductivity and superior reliability by minimizing contact points and mechanical wear, leading to improved signal stability and reduced downtime in critical systems. Performance analysis reveals hardwired setups excel in environments demanding unwavering connection stability, while quick disconnects provide flexibility without significant compromise in less rigorous applications.

Cost Implications: Quick Disconnect vs Hardwired

Quick disconnect connections typically incur higher initial costs due to specialized connectors and installation labor, but offer reduced maintenance expenses by simplifying repairs and replacements. Hardwired connections generally involve lower upfront investment in materials and labor but can lead to increased downtime and higher long-term service costs during troubleshooting or component swaps. Evaluating total cost of ownership reveals quick disconnect systems provide financial advantages in environments prioritizing flexibility and frequent equipment changes.

Use Cases and Applications

Quick disconnect connectors are ideal for applications requiring frequent maintenance or equipment swaps, such as industrial machinery, automotive diagnostics, and consumer electronics where fast, tool-free disconnection is essential. Hardwired connections are preferred in permanent installations like building wiring, aerospace systems, and medical devices, offering superior reliability and vibration resistance. Selecting between these connection types depends on factors like ease of access, environmental conditions, and the criticality of uninterrupted power or signal flow.

Pros and Cons Overview

Quick disconnect connectors offer ease of installation and maintenance, enabling fast equipment swaps and reducing downtime, but may introduce slightly higher resistance and potential points of failure. Hardwired connections provide superior durability, stable electrical performance, and minimal signal loss, yet they require more labor-intensive installation and complicate repairs or upgrades. Choosing between the two depends on the specific application requirements for flexibility, reliability, and maintenance efficiency.

Choosing the Right Connection for Your Needs

Choosing the right connection depends on your project's flexibility and maintenance requirements. Quick disconnect connectors offer ease of installation and fast removal, ideal for systems needing frequent updates or troubleshooting. Hardwired connections provide a more secure, permanent setup preferred in high-vibration or safety-critical environments.

Quick Disconnect vs Hardwired Connection Infographic

libmatt.com

libmatt.com