HART devices use the Highway Addressable Remote Transducer protocol to enable digital communication over traditional analog wiring, providing enhanced diagnostic and configuration capabilities. Non-HART devices operate solely with analog signals, limiting real-time data access and remote management options for your instrumentation system.

Table of Comparison

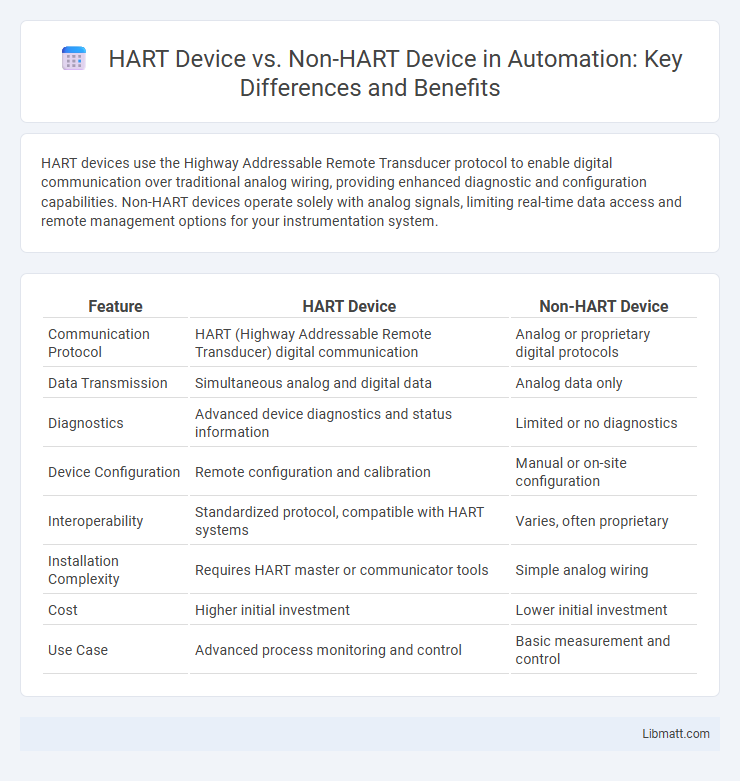

| Feature | HART Device | Non-HART Device |

|---|---|---|

| Communication Protocol | HART (Highway Addressable Remote Transducer) digital communication | Analog or proprietary digital protocols |

| Data Transmission | Simultaneous analog and digital data | Analog data only |

| Diagnostics | Advanced device diagnostics and status information | Limited or no diagnostics |

| Device Configuration | Remote configuration and calibration | Manual or on-site configuration |

| Interoperability | Standardized protocol, compatible with HART systems | Varies, often proprietary |

| Installation Complexity | Requires HART master or communicator tools | Simple analog wiring |

| Cost | Higher initial investment | Lower initial investment |

| Use Case | Advanced process monitoring and control | Basic measurement and control |

Introduction to HART and Non-HART Devices

HART devices utilize the Highway Addressable Remote Transducer protocol to enable two-way digital communication over analog wiring, enhancing diagnostic capabilities and device configuration. Non-HART devices rely solely on analog signals, limiting communication to simple process variable transmission without advanced diagnostics. The integration of HART technology improves process transparency and maintenance efficiency compared to traditional non-HART instrumentation.

What is a HART Device?

A HART Device is a field instrument that uses the Highway Addressable Remote Transducer (HART) protocol to enable digital communication over traditional 4-20 mA analog wiring. It allows for two-way communication between smart devices and control systems, providing enhanced diagnostics, configuration, and real-time data monitoring. Unlike Non-HART Devices, which only transmit analog signals, HART Devices deliver both analog and digital information, improving operational efficiency and maintenance capabilities.

What is a Non-HART Device?

A Non-HART device is an industrial instrument that operates without the HART (Highway Addressable Remote Transducer) communication protocol, relying solely on analog signals such as 4-20 mA for data transmission. Unlike HART devices, which enable digital communication alongside analog signals for diagnostics and configuration, Non-HART devices lack this capability, limiting remote monitoring and advanced control functions. These devices are commonly used in simpler process control systems where digital communication infrastructure is unnecessary or unavailable.

Key Differences Between HART and Non-HART Devices

HART devices utilize the Highway Addressable Remote Transducer protocol, enabling two-way digital communication over analog wiring for enhanced diagnostics and configuration. Non-HART devices rely solely on analog signals, limiting communication to basic process values without advanced diagnostics or remote configuration capabilities. Key differences include HART's ability to transmit multiple variables simultaneously, support device status monitoring, and facilitate seamless integration with smart control systems, whereas non-HART devices offer simpler, less flexible operation.

Communication Protocols and Data Transmission

HART devices utilize a hybrid communication protocol combining analog and digital signals, enabling simultaneous transmission of process variables and diagnostic data over the same wiring. Non-HART devices typically rely on traditional analog signals, such as 4-20 mA, which limit data transmission to basic measurement values without additional diagnostic information. Your process control can benefit from HART devices by improving data richness and enabling remote device management and diagnostics through digital communication.

Advantages of HART Devices

HART devices offer enhanced communication capabilities by combining analog signals with digital data, enabling real-time diagnostics and device configuration without interrupting the process. These devices improve maintenance efficiency and troubleshooting through accessible device-specific data and remote monitoring features. Compatibility with existing analog infrastructure reduces installation costs while delivering improved accuracy and reliability in industrial automation systems.

Limitations of Non-HART Devices

Non-HART devices lack digital communication capabilities, restricting real-time diagnostics, parameter adjustments, and advanced data exchange, which limits operational efficiency and predictive maintenance. Their inability to support two-way communication hinders remote monitoring and troubleshooting, increasing downtime and maintenance costs. Non-HART devices often require manual configuration and lack compatibility with modern asset management systems, reducing overall process control accuracy and responsiveness.

Application Areas and Use Cases

HART devices excel in process industries such as oil and gas, chemical, and pharmaceuticals, where precise diagnostics and device management improve plant efficiency and reduce downtime. Non-HART devices remain common in simpler applications like basic flow measurement and level detection, where advanced communication is less critical. Your choice between HART and non-HART devices depends on the complexity of your application's monitoring and control requirements.

Integration and Compatibility Considerations

HART devices utilize the Highway Addressable Remote Transducer protocol, enabling seamless integration with smart control systems and ensuring compatibility with modern asset management solutions. Non-HART devices often rely on analog signals, which can limit direct communication and require additional converters or interfaces for integration. Your choice between HART and non-HART devices impacts system interoperability, maintenance efficiency, and future scalability in industrial automation environments.

Choosing Between HART and Non-HART Devices

Choosing between HART and Non-HART devices depends on your need for communication and diagnostics capabilities; HART devices provide two-way digital communication over traditional analog signals, enabling real-time data and remote troubleshooting. Non-HART devices rely solely on analog signals, making them simpler and often more cost-effective but lacking advanced diagnostic features. For applications requiring enhanced monitoring and predictive maintenance, HART devices offer significant advantages in improving operational efficiency.

HART Device vs Non-HART Device Infographic

libmatt.com

libmatt.com