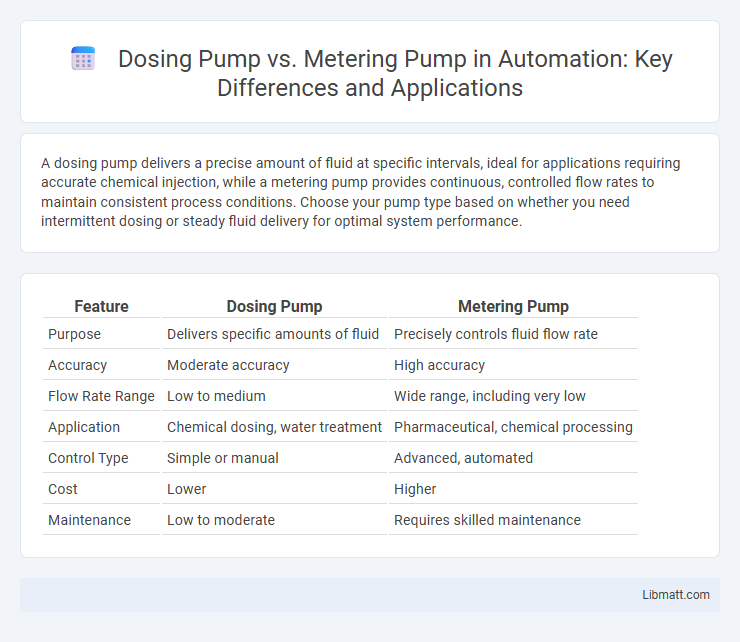

A dosing pump delivers a precise amount of fluid at specific intervals, ideal for applications requiring accurate chemical injection, while a metering pump provides continuous, controlled flow rates to maintain consistent process conditions. Choose your pump type based on whether you need intermittent dosing or steady fluid delivery for optimal system performance.

Table of Comparison

| Feature | Dosing Pump | Metering Pump |

|---|---|---|

| Purpose | Delivers specific amounts of fluid | Precisely controls fluid flow rate |

| Accuracy | Moderate accuracy | High accuracy |

| Flow Rate Range | Low to medium | Wide range, including very low |

| Application | Chemical dosing, water treatment | Pharmaceutical, chemical processing |

| Control Type | Simple or manual | Advanced, automated |

| Cost | Lower | Higher |

| Maintenance | Low to moderate | Requires skilled maintenance |

Introduction to Dosing Pumps and Metering Pumps

Dosing pumps precisely control the flow rate of liquids, commonly used in water treatment, chemical processing, and pharmaceuticals to inject exact quantities of fluids. Metering pumps offer highly accurate volumetric flow rates, essential for applications requiring precise fluid measurement and repeatable dosing cycles. Both pumps are designed to deliver controlled, consistent fluid amounts, but metering pumps emphasize volumetric accuracy while dosing pumps focus on adjustable flow control for various chemical concentrations.

Defining Dosing Pumps: Function and Applications

Dosing pumps are precision devices designed to deliver accurate volumes of liquid chemicals or additives into a process stream, ensuring consistent concentration levels. Commonly used in water treatment, chemical manufacturing, and pharmaceuticals, these pumps maintain controlled chemical injection to optimize process efficiency and safety. Your choice of dosing pump should reflect the specific flow rate and pressure requirements of your application for optimal performance.

Understanding Metering Pumps: Features and Uses

Metering pumps are precision devices designed to deliver accurate volumes of fluids at controlled flow rates, essential in chemical dosing and water treatment applications. These pumps typically feature adjustable stroke lengths and speeds, allowing fine-tuned control over fluid injection, ensuring consistent process performance. Understanding your specific metering pump's capabilities helps optimize its use in industries requiring exact chemical dosing and flow regulation.

Key Differences Between Dosing and Metering Pumps

Dosing pumps deliver precise volumes of fluid at set intervals, ensuring accurate chemical injection for process control. Metering pumps provide variable flow rates proportional to input signals, allowing real-time adjustments in fluid delivery based on system demands. The primary difference lies in dosing pumps' fixed volume accuracy versus metering pumps' dynamic flow control capability.

Accuracy and Precision: Comparing Performance

Dosing pumps deliver fluids at a set volume with consistent flow rates, ensuring high dosing accuracy for applications requiring precise chemical injection or fluid control. Metering pumps offer superior precision by adjusting flow rates dynamically based on system feedback, enabling fine control in processes needing exact volumetric delivery. Both pumps excel in accuracy and precision, but metering pumps are preferred where variable flow and precise adjustments are critical.

Typical Industries and Applications

Dosing pumps are commonly used in water treatment, chemical manufacturing, and food processing industries for precise additive injection and chemical dosing applications. Metering pumps find extensive use in pharmaceuticals, oil and gas, and wastewater treatment where exact flow control and accurate fluid measurement are critical. Both pump types serve essential roles in laboratory testing, agriculture, and beverage production for controlled fluid transfer and consistent process management.

Advantages of Dosing Pumps

Dosing pumps offer precise control over fluid delivery, enabling accurate and consistent chemical injection in industrial and water treatment applications. Their simple design and ease of maintenance reduce downtime and operational costs compared to metering pumps. Enhanced reliability and versatility in handling a wide range of fluid viscosities make dosing pumps ideal for continuous, low-flow dosing tasks.

Benefits of Metering Pumps

Metering pumps offer precise flow control with high accuracy, making them ideal for applications requiring exact chemical dosing. Their ability to handle a wide range of viscosities and pressures ensures consistent performance in industrial processes like water treatment and chemical manufacturing. Enhanced reliability and adjustable stroke settings further optimize metering pumps for efficient, safe, and cost-effective fluid delivery.

Factors to Consider When Choosing a Pump

When choosing between a dosing pump and a metering pump, consider flow rate accuracy, pressure capacity, and chemical compatibility to ensure precise fluid handling in your application. Dosing pumps are typically ideal for low flow rates and chemical injection, while metering pumps excel in providing consistent flow under varying pressure conditions. Your choice should align with the required precision, fluid type, and system pressure to optimize performance and reliability.

Conclusion: Which Pump Is Best for Your Needs?

Choosing between a dosing pump and a metering pump depends on the precise application requirements, such as flow rate accuracy, chemical compatibility, and operational environment. Dosing pumps excel in delivering exact chemical volumes at controlled intervals, ideal for water treatment and chemical injection, while metering pumps offer versatile, continuous flow control suitable for industrial processes requiring precise fluid management. Evaluating factors like pressure capacity, maintenance needs, and cost-effectiveness ensures selecting the pump that best meets your specific dosing or metering demands.

Dosing Pump vs Metering Pump Infographic

libmatt.com

libmatt.com