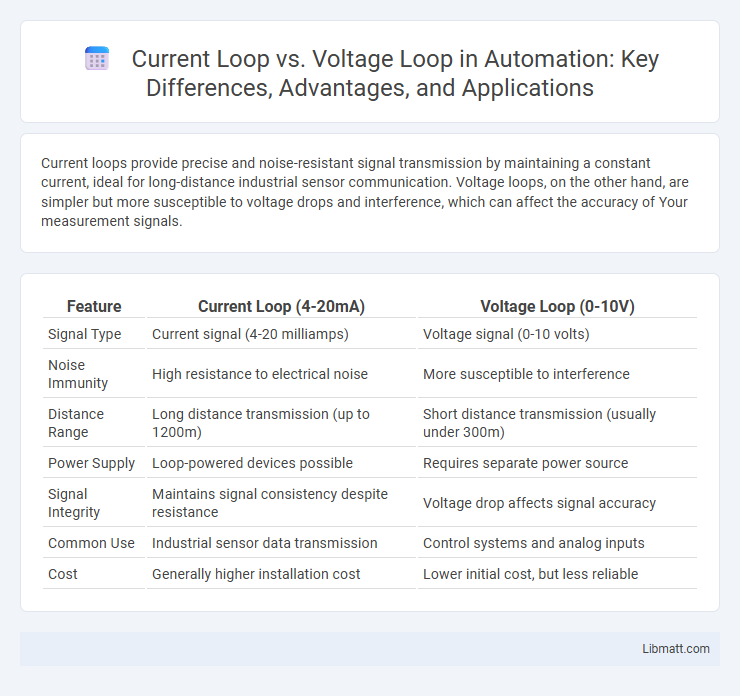

Current loops provide precise and noise-resistant signal transmission by maintaining a constant current, ideal for long-distance industrial sensor communication. Voltage loops, on the other hand, are simpler but more susceptible to voltage drops and interference, which can affect the accuracy of Your measurement signals.

Table of Comparison

| Feature | Current Loop (4-20mA) | Voltage Loop (0-10V) |

|---|---|---|

| Signal Type | Current signal (4-20 milliamps) | Voltage signal (0-10 volts) |

| Noise Immunity | High resistance to electrical noise | More susceptible to interference |

| Distance Range | Long distance transmission (up to 1200m) | Short distance transmission (usually under 300m) |

| Power Supply | Loop-powered devices possible | Requires separate power source |

| Signal Integrity | Maintains signal consistency despite resistance | Voltage drop affects signal accuracy |

| Common Use | Industrial sensor data transmission | Control systems and analog inputs |

| Cost | Generally higher installation cost | Lower initial cost, but less reliable |

Introduction to Current Loop and Voltage Loop

Current loops transmit signals by varying electrical current, commonly used in industrial control systems like 4-20mA loops for reliable long-distance communication with minimal interference. Voltage loops rely on voltage changes to convey information, ideal for shorter distances or low-impedance loads where signal integrity is maintained. Your choice between current and voltage loops depends on factors like distance, environmental noise, and required signal accuracy.

Fundamental Principles of Current and Voltage Loops

Current loops transmit signals as a constant current, usually 4-20 mA, enabling resistance-independent communication in industrial sensor systems. Voltage loops control signal transmission via voltage levels, relying on voltage stability affected by line resistance and impedance. Fundamental principles highlight current loops' robustness against electrical noise and resistance variations, while voltage loops offer simpler circuit design for short distances.

Key Differences Between Current Loop and Voltage Loop

Current loops measure and transmit signals using a consistent current, typically 4-20 mA, ensuring resistance-immune communication ideal for long distances. Voltage loops rely on voltage variations, typically 0-10 V, and are more susceptible to signal degradation from resistance, limiting their effective range. Current loops provide higher noise immunity and easier fault detection compared to voltage loops, which offer simpler wiring but lower accuracy in industrial control systems.

Advantages of Using Current Loop Systems

Current loop systems offer superior noise immunity and long-distance signal transmission capabilities, making them ideal for industrial environments with electrical interference. Their standardized 4-20 mA signal range simplifies device integration and ensures consistent, accurate sensor readings. You benefit from enhanced reliability and easier troubleshooting when using current loop systems in process control applications.

Advantages of Using Voltage Loop Systems

Voltage loop systems offer precise control over electrical potential, ensuring consistent voltage levels that enhance device performance and reliability. They provide faster response times and improved stability compared to current loop systems, making them ideal for applications requiring accurate voltage regulation. By using a voltage loop, your equipment benefits from reduced noise interference and better compatibility with sensitive electronic components.

Applications in Industrial Automation

Current loop systems excel in industrial automation by providing highly reliable long-distance signal transmission with resistance to electrical noise, making them ideal for process control and sensor data acquisition. Voltage loops are commonly used where signal length is short and precise voltage levels are critical, such as in analog control circuits and instrumentation within factory environments. You benefit from choosing the appropriate loop type based on factors like environment, wiring distance, and accuracy requirements in your industrial automation setup.

Signal Integrity and Noise Immunity Comparison

Current loop systems offer superior noise immunity due to their constant current flow, which reduces susceptibility to voltage drops and electromagnetic interference, making them ideal for long-distance signal transmission. Voltage loop configurations, while simpler, are more prone to signal degradation from impedance changes and external noise, impacting signal integrity especially in electrically noisy environments. You should consider a current loop for critical applications demanding robust signal fidelity and minimal interference over extended distances.

Wiring and Installation Considerations

Wiring and installation of current loops typically require two-wire or four-wire configurations, providing noise immunity over long distances by transmitting signals as constant current, which reduces voltage drop impact. Voltage loops rely on three-wire or four-wire setups, making them more susceptible to signal degradation due to wiring resistance and electromagnetic interference. When optimizing your system, consider current loops for challenging environments requiring reliable long-distance signal transmission and simpler wiring schemes.

Cost Implications and Maintenance

Current loop systems generally have lower installation and maintenance costs due to simpler wiring and better noise immunity, reducing the need for expensive shielding and troubleshooting. Voltage loops often require more complex infrastructure and frequent calibration, increasing ongoing maintenance expenses and potential downtime. Choosing a current loop can help you minimize operational costs while ensuring reliable system performance.

Choosing the Right Loop for Your Application

Selecting the correct control loop depends on the specific requirements of your application, such as accuracy, response time, and environmental factors. Current loops, often using 4-20 mA signals, provide superior noise immunity and are ideal for long-distance transmission or harsh industrial environments. Voltage loops offer faster response times and are suitable for short-range, low-noise scenarios where precision voltage measurement is critical.

Current Loop vs Voltage Loop Infographic

libmatt.com

libmatt.com