Remote I/O enables your system to extend input/output capabilities over a network, allowing flexible device placement and centralized control, while Local I/O offers direct, faster connections with lower latency for immediate data acquisition. Choosing between Remote I/O and Local I/O depends on factors like scalability, distance, cost, and the critical need for response time in your application.

Table of Comparison

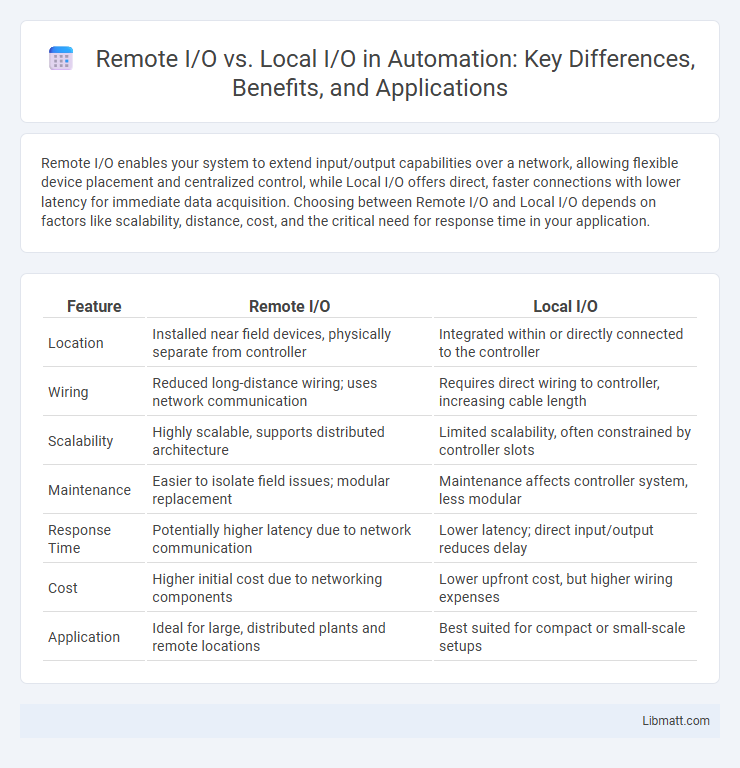

| Feature | Remote I/O | Local I/O |

|---|---|---|

| Location | Installed near field devices, physically separate from controller | Integrated within or directly connected to the controller |

| Wiring | Reduced long-distance wiring; uses network communication | Requires direct wiring to controller, increasing cable length |

| Scalability | Highly scalable, supports distributed architecture | Limited scalability, often constrained by controller slots |

| Maintenance | Easier to isolate field issues; modular replacement | Maintenance affects controller system, less modular |

| Response Time | Potentially higher latency due to network communication | Lower latency; direct input/output reduces delay |

| Cost | Higher initial cost due to networking components | Lower upfront cost, but higher wiring expenses |

| Application | Ideal for large, distributed plants and remote locations | Best suited for compact or small-scale setups |

Introduction to Remote I/O and Local I/O

Remote I/O systems enable data acquisition and control functions to be distributed across extended distances, connecting field devices via network protocols to a central controller, enhancing scalability and reducing wiring complexity. Local I/O refers to input/output modules physically located within or near the control system cabinet, offering faster response times and simpler troubleshooting due to proximity. Your choice between Remote I/O and Local I/O depends on factors like installation environment, system size, and communication speed requirements.

Defining Remote I/O: Key Features and Functions

Remote I/O systems enable data acquisition and control operations to be conducted at a distance from the central controller, connecting sensors and actuators via communication networks such as Ethernet or fieldbus protocols. Key features include simplified wiring, improved scalability, real-time data transmission, and enhanced flexibility in industrial automation setups. Functions primarily involve gathering input/output signals remotely, converting them to digital data, and transmitting this information reliably to a primary control system for processing and decision making.

Understanding Local I/O: Core Concepts and Benefits

Local I/O refers to input/output devices directly connected to a controller or computer, ensuring faster data transfer and reduced latency compared to Remote I/O. Your control system benefits from increased reliability and simpler troubleshooting since signals travel shorter distances and face less interference. Understanding Local I/O's core concepts helps optimize system responsiveness and maintain high operational efficiency in industrial automation environments.

Architecture Differences: Remote vs Local I/O Systems

Remote I/O systems feature a decentralized architecture where input/output modules are distributed and connected to a central controller via communication networks, reducing wiring complexity and enabling flexible installation over larger distances. Local I/O systems have centralized modules directly connected to the controller, offering faster response times but with increased wiring and limited scalability. Your choice depends on factors like system size, installation environment, and real-time performance requirements.

Communication Protocols in Remote and Local I/O

Remote I/O systems commonly utilize industrial communication protocols such as Modbus, Profibus, and Ethernet/IP to transmit data over long distances to centralized controllers, ensuring reliable and efficient communication in distributed automation environments. Local I/O typically relies on direct point-to-point connections using simpler protocols like TTL, SPI, or I2C for high-speed, low-latency interactions with nearby devices. Selecting the appropriate communication protocol depends on factors like distance, bandwidth, real-time requirements, and network topology in industrial control systems.

Installation and Maintenance: Cost and Complexity

Remote I/O systems typically incur higher initial installation costs due to the need for extended communication wiring and network infrastructure, but they reduce complexity by centralizing control and minimizing local hardware. Local I/O installations often have lower upfront expenses with simpler wiring directly to the controller, yet maintenance can be more time-consuming and costly over time due to dispersed equipment and increased points of failure. Your choice depends on weighing the long-term savings in maintenance and scalability offered by remote I/O against the straightforward setup and immediate cost benefits of local I/O.

Performance Comparison: Speed, Latency, and Reliability

Remote I/O systems often experience higher latency and reduced speed compared to Local I/O due to data transmission over networks, impacting real-time performance. Local I/O provides faster response times and greater reliability by directly interfacing with the system hardware, minimizing communication delays. Your choice between Remote and Local I/O should consider the criticality of low latency and consistent data transfer for optimal operational performance.

Scalability and Flexibility: Remote vs Local I/O

Remote I/O offers superior scalability by enabling easy expansion of input/output points across multiple locations without the constraints of physical proximity to the central controller. Local I/O, while simpler to implement, is limited by fixed hardware capacity and proximity, restricting flexibility to adapt to growing or changing system requirements. Choosing Remote I/O enhances flexibility in network configurations and supports distributed control architectures, making it ideal for large-scale or modular systems.

Industrial Applications: Choosing the Right I/O Solution

Industrial applications require selecting the appropriate I/O solution to optimize system performance and reliability. Remote I/O offers flexibility and scalability for distributed control systems, reducing wiring complexity and enabling real-time data acquisition from multiple field devices. Local I/O provides faster response times and enhanced security by keeping connections close to the central controller, making it ideal for high-speed, critical process controls.

Conclusion: Making the Best Choice for Your System

Choosing between Remote I/O and Local I/O depends on factors such as system size, latency requirements, and maintenance capabilities. Remote I/O offers scalability and centralized management for distributed systems, while Local I/O ensures faster response times and simpler troubleshooting in compact setups. Assessing communication protocols, network reliability, and cost implications will guide the optimal integration for enhanced system performance.

Remote I/O vs Local I/O Infographic

libmatt.com

libmatt.com