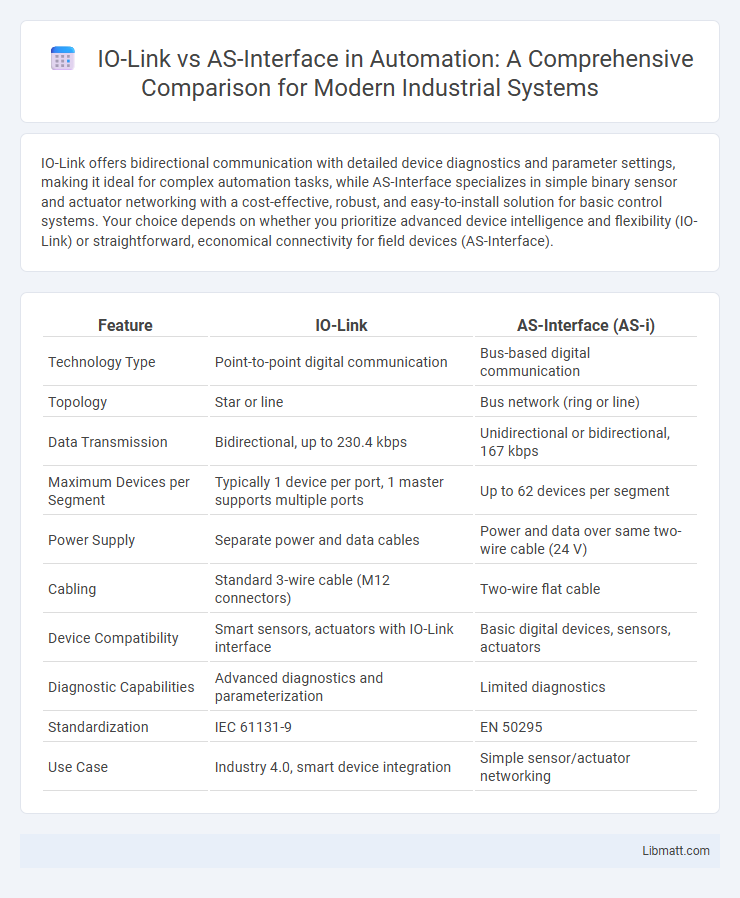

IO-Link offers bidirectional communication with detailed device diagnostics and parameter settings, making it ideal for complex automation tasks, while AS-Interface specializes in simple binary sensor and actuator networking with a cost-effective, robust, and easy-to-install solution for basic control systems. Your choice depends on whether you prioritize advanced device intelligence and flexibility (IO-Link) or straightforward, economical connectivity for field devices (AS-Interface).

Table of Comparison

| Feature | IO-Link | AS-Interface (AS-i) |

|---|---|---|

| Technology Type | Point-to-point digital communication | Bus-based digital communication |

| Topology | Star or line | Bus network (ring or line) |

| Data Transmission | Bidirectional, up to 230.4 kbps | Unidirectional or bidirectional, 167 kbps |

| Maximum Devices per Segment | Typically 1 device per port, 1 master supports multiple ports | Up to 62 devices per segment |

| Power Supply | Separate power and data cables | Power and data over same two-wire cable (24 V) |

| Cabling | Standard 3-wire cable (M12 connectors) | Two-wire flat cable |

| Device Compatibility | Smart sensors, actuators with IO-Link interface | Basic digital devices, sensors, actuators |

| Diagnostic Capabilities | Advanced diagnostics and parameterization | Limited diagnostics |

| Standardization | IEC 61131-9 | EN 50295 |

| Use Case | Industry 4.0, smart device integration | Simple sensor/actuator networking |

Introduction to IO-Link and AS-Interface

IO-Link is a point-to-point communication protocol designed for smart sensors and actuators, enabling bidirectional data exchange and enhanced device diagnostics in industrial automation. AS-Interface (Actuator-Sensor Interface) is a two-wire bus system primarily used for connecting simple field devices like switches and sensors in a cost-effective and straightforward manner. Both technologies improve connectivity and device integration but differ significantly in network topology, data complexity, and application scope.

Overview of Industrial Communication Protocols

IO-Link provides point-to-point communication for sensor and actuator devices, enabling detailed diagnostics and parameterization with standardized digital signals. AS-Interface (AS-i) offers a simpler, cost-effective network solution primarily designed for binary sensor and actuator integration in industrial automation, supporting multiple devices on a single cable. Understanding these protocols helps optimize Your industrial communication infrastructure for specific application needs, balancing complexity, device capability, and installation costs.

Architecture and Topology Comparison

IO-Link features a point-to-point architecture enabling direct communication between sensors or actuators and a master, facilitating detailed data exchange and diagnostics. AS-Interface employs a simple bus topology connecting multiple devices in a daisy-chain configuration, optimizing easy and cost-effective integration of binary I/O signals. Your choice between IO-Link and AS-Interface depends on the required complexity and scalability of the network within your industrial automation system.

Communication Speed and Data Transmission

IO-Link supports communication speeds up to 230.4 kbps, enabling fast and efficient bidirectional data exchange between sensors, actuators, and control systems. In contrast, AS-Interface offers a lower communication speed of 167 kbps, primarily designed for simple binary and analog signal transmission in networked field devices. IO-Link's point-to-point communication allows detailed parameter and diagnostic data transfer, while AS-Interface uses a master-slave protocol optimized for straightforward sensor-actuator networks with limited data complexity.

Device Compatibility and Integration

IO-Link supports seamless integration with a wide range of smart devices including sensors and actuators from multiple manufacturers, enabling enhanced device compatibility and flexible system expansion. AS-Interface primarily connects simple binary devices and actuators, offering limited device compatibility but straightforward integration for basic automation tasks. Your choice depends on whether you prioritize advanced device communication and diagnostics (IO-Link) or cost-effective, simple device networking (AS-Interface).

Installation and Wiring Differences

IO-Link uses standard unshielded cables and supports point-to-point wiring with a maximum length of 20 meters, simplifying device installation without special infrastructure. AS-Interface employs a two-wire flat cable with a specific polarity and voltage, designed for simple, low-cost wiring in distributed I/O networks up to 100 meters. The key difference lies in IO-Link's ability to connect intelligent sensors using existing standard cables, whereas AS-Interface requires dedicated cabling for power and communication integration.

Diagnostics and Maintenance Features

IO-Link provides advanced diagnostics with real-time data monitoring, error messages, and predictive maintenance capabilities, enabling quick fault detection and resolution. AS-Interface offers basic diagnostics primarily focused on simple device status and network faults without detailed sensor-level insights. The superior diagnostic granularity and maintenance support of IO-Link significantly enhance system uptime and reduce troubleshooting time.

Scalability and Expansion Potential

IO-Link offers superior scalability and expansion potential compared to AS-Interface by supporting point-to-point communication with intelligent devices, allowing easy integration and real-time data exchange. Its decentralized architecture enables flexible expansion without complex wiring changes, making it ideal for modular systems and future-proof automation. Your system benefits from seamless device addition and enhanced diagnostics, optimizing operational efficiency and minimizing downtime.

Cost Considerations and ROI

IO-Link offers lower installation and wiring costs due to its use of standard cables and point-to-point connections, which reduces complexity and maintenance expenses compared to AS-Interface's bus topology. AS-Interface may require higher initial investment for specialized components and network design, but it supports larger device networks, potentially enhancing ROI in extensive systems. Your choice should balance upfront costs with long-term efficiency gains and scalability to maximize return on investment.

Choosing the Right Protocol for Your Application

Selecting between IO-Link and AS-Interface depends on the complexity and type of device communication required in your application. IO-Link offers point-to-point communication with advanced diagnostic data, ideal for smart sensors and actuators needing detailed status monitoring and parameterization. AS-Interface is optimized for simple binary and analog device networks, providing cost-effective and robust solutions for large sensor/actuator assemblies in harsh industrial environments.

IO-Link vs AS-Interface Infographic

libmatt.com

libmatt.com