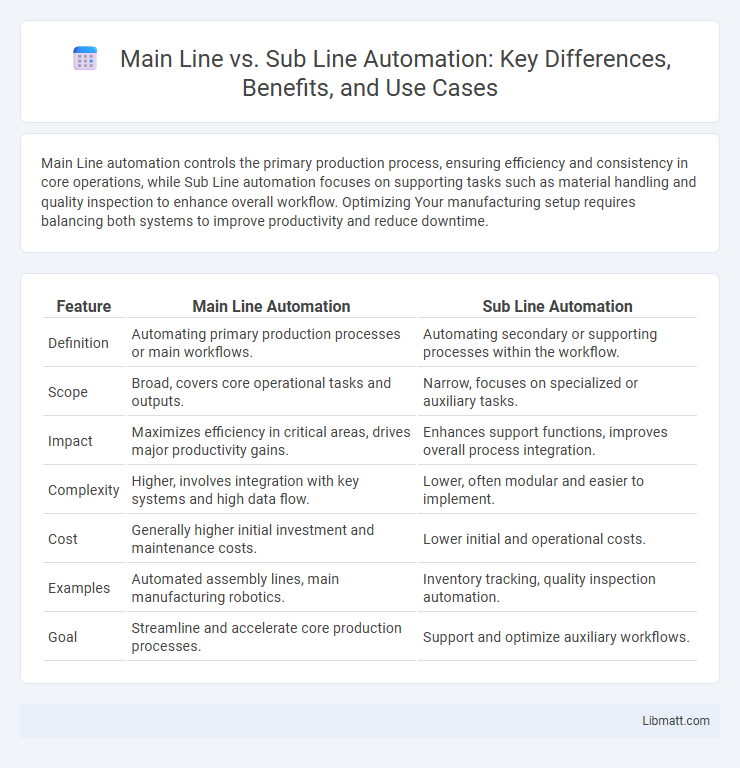

Main Line automation controls the primary production process, ensuring efficiency and consistency in core operations, while Sub Line automation focuses on supporting tasks such as material handling and quality inspection to enhance overall workflow. Optimizing Your manufacturing setup requires balancing both systems to improve productivity and reduce downtime.

Table of Comparison

| Feature | Main Line Automation | Sub Line Automation |

|---|---|---|

| Definition | Automating primary production processes or main workflows. | Automating secondary or supporting processes within the workflow. |

| Scope | Broad, covers core operational tasks and outputs. | Narrow, focuses on specialized or auxiliary tasks. |

| Impact | Maximizes efficiency in critical areas, drives major productivity gains. | Enhances support functions, improves overall process integration. |

| Complexity | Higher, involves integration with key systems and high data flow. | Lower, often modular and easier to implement. |

| Cost | Generally higher initial investment and maintenance costs. | Lower initial and operational costs. |

| Examples | Automated assembly lines, main manufacturing robotics. | Inventory tracking, quality inspection automation. |

| Goal | Streamline and accelerate core production processes. | Support and optimize auxiliary workflows. |

Introduction to Main Line and Sub Line Automation

Main Line Automation refers to the integration of automated processes along the primary production pathway, optimizing core manufacturing operations such as assembly, packaging, and inspection. Sub Line Automation encompasses the automation of auxiliary or supporting processes that feed into or complement the main line, including material handling, quality control, and component preparation. Both systems enhance overall production efficiency by streamlining workflows and reducing manual intervention in manufacturing environments.

Key Differences Between Main Line and Sub Line Automation

Main Line automation primarily focuses on controlling and optimizing the primary production or distribution channels, ensuring high-volume throughput and minimizing downtime in core processes. Sub Line automation targets secondary or auxiliary processes that support the main line, often involving specialized tasks, lower volume outputs, and more flexible operations. Key differences include scale and complexity, with Main Line automation emphasizing robustness and speed, while Sub Line automation prioritizes adaptability and precision for niche functions.

Benefits of Main Line Automation

Main Line Automation enhances production efficiency by streamlining core processes, reducing manual intervention, and minimizing downtime. This automation improves product quality through consistent operations and real-time monitoring, leading to fewer defects and higher throughput. Your manufacturing system gains scalability and flexibility, enabling faster response to market demands and increasing overall profitability.

Advantages of Sub Line Automation

Sub line automation enhances production flexibility by allowing smaller, specialized segments of the manufacturing process to operate independently, reducing downtime and increasing efficiency. It enables targeted quality control and faster troubleshooting within specific sub-processes, minimizing the impact on the main production line. This localized automation approach often results in cost savings and easier scalability compared to full main line automation systems.

Challenges in Main Line Automation

Main Line Automation faces significant challenges such as managing high-speed production lines that demand precise synchronization and minimal downtime. The complexity of integrating various machines while maintaining consistent product quality requires advanced control systems and real-time monitoring. Your manufacturing process must address issues like equipment reliability and scalability to ensure efficient Main Line Automation implementation.

Common Issues in Sub Line Automation

Sub line automation often faces challenges such as inconsistent signal quality, synchronization errors, and limited integration with main line systems, which can lead to operational delays and safety concerns. Common issues include frequent false triggers in sensors, communication lags causing misaligned data flow, and difficulties in managing diverse equipment protocols. Addressing these problems requires robust error-handling mechanisms and enhanced compatibility standards to ensure seamless coordination between sub line and main line automation.

Choosing the Right Automation Approach

Choosing the right automation approach depends on your production volume and complexity requirements, with main line automation ideal for high-speed, continuous processes and sub line automation suited for specialized, flexible tasks. Main line automation integrates directly into the primary production flow to maximize efficiency and reduce cycle times, while sub line automation provides modular support and scalability for batch or variable production. Evaluating your operational goals and workflow allows you to select the optimal balance between throughput, customization, and cost-effectiveness.

Cost Implications: Main Line vs Sub Line

Main Line automation typically requires higher upfront investment due to its complexity and integration across the primary production workflow, whereas Sub Line automation offers a cost-effective solution by targeting specific processes or machines. Your choice between Main Line and Sub Line automation should consider not only initial expenses but also long-term maintenance and scalability costs. Sub Line automation often allows for easier upgrades and lower modification costs, making it ideal for businesses balancing efficiency with budget constraints.

Integration Strategies for Seamless Automation

Integration strategies for seamless automation emphasize synchronized communication protocols and unified control systems between main line and sub line automation components. Employing middleware platforms and real-time data exchange ensures consistent operational flow and minimizes downtime across production stages. Leveraging IoT-enabled devices and standardized API interfaces enhances scalability and flexibility in complex manufacturing environments.

Future Trends in Line Automation Technology

Future trends in main line versus sub line automation emphasize increased integration of AI-driven predictive maintenance and real-time data analytics to enhance operational efficiency. Main line automation is advancing towards fully autonomous production workflows with seamless connectivity across multiple manufacturing stages, while sub line automation focuses on modular, flexible systems that adapt quickly to changing product specifications. Edge computing and IoT sensors are becoming critical in both main and sub line automation for reducing latency and enabling proactive decision-making in complex industrial environments.

Main Line vs Sub Line Automation Infographic

libmatt.com

libmatt.com