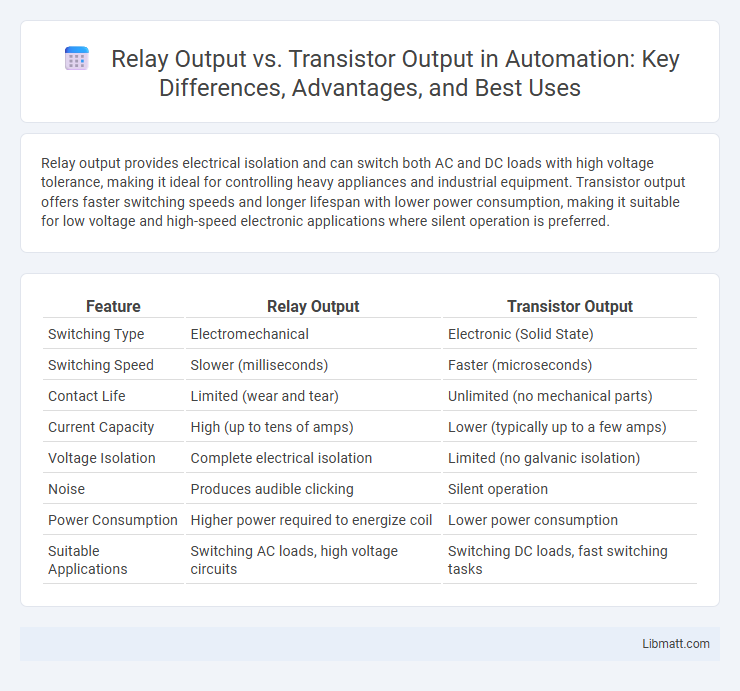

Relay output provides electrical isolation and can switch both AC and DC loads with high voltage tolerance, making it ideal for controlling heavy appliances and industrial equipment. Transistor output offers faster switching speeds and longer lifespan with lower power consumption, making it suitable for low voltage and high-speed electronic applications where silent operation is preferred.

Table of Comparison

| Feature | Relay Output | Transistor Output |

|---|---|---|

| Switching Type | Electromechanical | Electronic (Solid State) |

| Switching Speed | Slower (milliseconds) | Faster (microseconds) |

| Contact Life | Limited (wear and tear) | Unlimited (no mechanical parts) |

| Current Capacity | High (up to tens of amps) | Lower (typically up to a few amps) |

| Voltage Isolation | Complete electrical isolation | Limited (no galvanic isolation) |

| Noise | Produces audible clicking | Silent operation |

| Power Consumption | Higher power required to energize coil | Lower power consumption |

| Suitable Applications | Switching AC loads, high voltage circuits | Switching DC loads, fast switching tasks |

Introduction to Output Types in Automation

Relay output and transistor output are crucial components in automation systems for controlling external devices. Relay outputs provide electrical isolation and can switch both AC and DC loads, making them versatile for high-power applications. Transistor outputs offer faster switching speeds and longer operational lifespans, ideal for low-voltage DC loads in high-frequency automation tasks.

What is a Relay Output?

A relay output is an electromechanical switch that controls electrical circuits by opening or closing contacts in response to an input signal. It offers electrical isolation between the control system and the load, making it suitable for switching high voltage or high current devices safely. Your choice of output depends on the application requirements, where relays provide durability and noise immunity compared to transistor outputs.

Understanding Transistor Output

Transistor output operates as a solid-state switch using semiconductor devices such as bipolar junction transistors or MOSFETs, enabling faster switching speeds and longer operational life compared to relay outputs. It provides low power consumption, silent operation, and minimal electromagnetic interference, making it ideal for integration with modern electronic circuits and microcontrollers. Transistor outputs are typically used in applications requiring high-speed switching and precise control without the mechanical wear associated with relay contacts.

Key Differences Between Relay and Transistor Outputs

Relay outputs use electromechanical switches to open or close circuits, providing galvanic isolation and handling higher voltages or currents. Transistor outputs rely on semiconductor switches for faster switching speeds, longer lifespan, and smaller physical size but typically require external circuitry to isolate loads. Your choice depends on the application's need for isolation, switching speed, voltage, and current requirements.

Advantages of Relay Outputs

Relay outputs offer superior electrical isolation by physically separating the control circuit from the load, reducing the risk of electrical noise interference and potential damage. They can handle higher voltage and current loads, making them ideal for switching heavy-duty equipment or inductive loads. Your system benefits from the reliable mechanical contact that ensures stable operation in harsh environments where semiconductor devices might fail.

Benefits of Transistor Outputs

Transistor outputs offer faster switching speeds and higher durability compared to relay outputs, making them ideal for high-frequency applications. They provide silent operation with no mechanical wear, enhancing system reliability and reducing maintenance costs. Their compact size and low power consumption contribute to efficient, space-saving designs in modern electronic devices.

Application Scenarios for Each Output Type

Relay outputs excel in applications requiring electrical isolation and the ability to switch high AC or DC loads, making them ideal for industrial automation, HVAC systems, and motor control. Transistor outputs are preferred in low-voltage DC circuits with fast switching needs, such as signal processing, PLC inputs, and electronic control systems. Selecting between relay and transistor outputs depends on load type, switching speed, isolation requirements, and electrical noise tolerance.

Reliability and Durability Comparison

Relay output offers high durability with mechanical contacts that can handle high voltages and currents, making it reliable for heavy-duty applications. Transistor output provides greater reliability in fast-switching and low-voltage operations due to its solid-state nature, eliminating mechanical wear and tear. Your choice depends on whether you prioritize long-term mechanical robustness or rapid, maintenance-free switching performance.

Choosing the Right Output for Your Project

Relay outputs provide electrical isolation and can switch high voltages and currents, making them ideal for controlling heavy loads such as motors and industrial equipment. Transistor outputs offer faster switching speeds, longer life expectancy, and are better suited for low voltage, low current applications like signal switching and LED indicators. Selecting the right output depends on factors like load type, switching speed, voltage level, and isolation requirements, ensuring optimal performance and longevity for your project.

Conclusion: Relay vs Transistor Output

Relay output offers mechanical isolation and can switch higher voltages and currents, making it suitable for applications requiring electrical separation and high power handling. Transistor output provides faster switching speeds, longer lifespan due to solid-state design, and lower power consumption, ideal for low-voltage control circuits and rapid switching. Choosing between relay and transistor outputs depends on factors like required voltage, current, switching speed, lifespan, and electrical isolation needs.

Relay Output vs Transistor Output Infographic

libmatt.com

libmatt.com