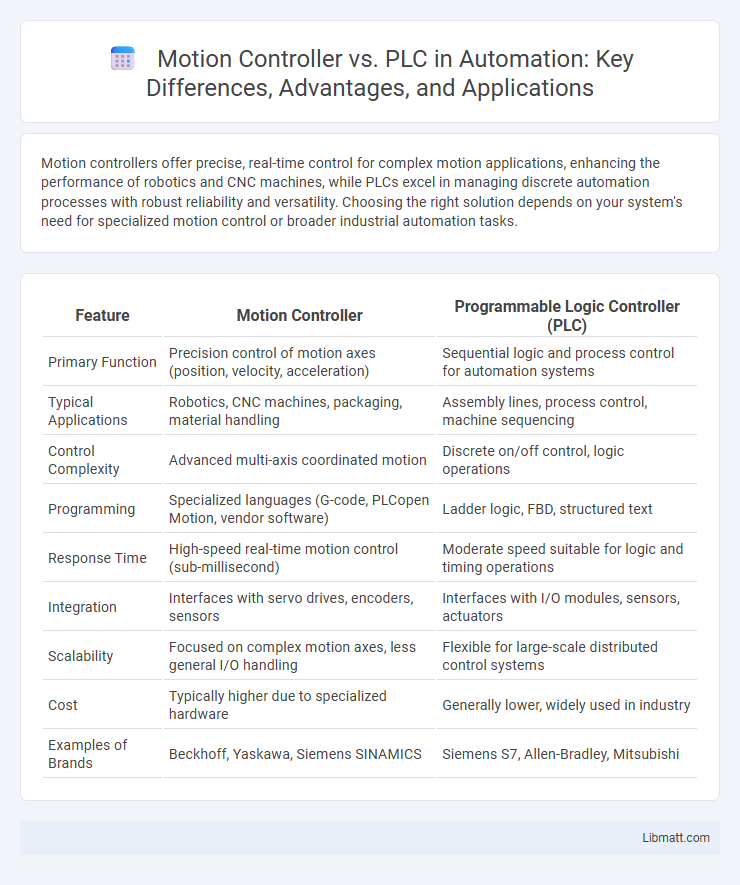

Motion controllers offer precise, real-time control for complex motion applications, enhancing the performance of robotics and CNC machines, while PLCs excel in managing discrete automation processes with robust reliability and versatility. Choosing the right solution depends on your system's need for specialized motion control or broader industrial automation tasks.

Table of Comparison

| Feature | Motion Controller | Programmable Logic Controller (PLC) |

|---|---|---|

| Primary Function | Precision control of motion axes (position, velocity, acceleration) | Sequential logic and process control for automation systems |

| Typical Applications | Robotics, CNC machines, packaging, material handling | Assembly lines, process control, machine sequencing |

| Control Complexity | Advanced multi-axis coordinated motion | Discrete on/off control, logic operations |

| Programming | Specialized languages (G-code, PLCopen Motion, vendor software) | Ladder logic, FBD, structured text |

| Response Time | High-speed real-time motion control (sub-millisecond) | Moderate speed suitable for logic and timing operations |

| Integration | Interfaces with servo drives, encoders, sensors | Interfaces with I/O modules, sensors, actuators |

| Scalability | Focused on complex motion axes, less general I/O handling | Flexible for large-scale distributed control systems |

| Cost | Typically higher due to specialized hardware | Generally lower, widely used in industry |

| Examples of Brands | Beckhoff, Yaskawa, Siemens SINAMICS | Siemens S7, Allen-Bradley, Mitsubishi |

Introduction to Motion Controllers and PLCs

Motion controllers are specialized devices designed to precisely manage the movement of machinery in automation systems, using real-time feedback to control servo drives and stepper motors. Programmable Logic Controllers (PLCs) are rugged industrial computers that execute control programs for a wide range of automation tasks, handling discrete and analog inputs and outputs to regulate processes. Both motion controllers and PLCs serve critical roles in industrial automation, with motion controllers focusing on dynamic motion control and PLCs offering versatile process control and monitoring.

Core Functions: Motion Controller vs PLC

Motion controllers specialize in precise control of movement, managing complex tasks like trajectory planning, speed regulation, and position feedback in real-time, crucial for robotics and CNC machines. PLCs focus on broader industrial automation by handling logic control, process sequencing, and I/O management, often integrating various sensors and actuators for system-wide operations. While motion controllers excel in dynamic motion tasks, PLCs provide robust control for overall system processes and safety interlocks.

System Architecture and Integration

Motion controllers typically feature dedicated hardware optimized for precise real-time motion control tasks, allowing seamless integration with servo drives and encoders within a distributed control architecture. Programmable Logic Controllers (PLCs) are designed with modular I/O systems and a centralized processing unit, supporting broad industrial automation integration through standardized communication protocols such as Ethernet/IP and Modbus. Combining motion controllers with PLCs in hybrid systems enhances flexibility, enabling synchronized control of complex machinery while maintaining robust system architecture and efficient data exchange.

Programming Differences and Flexibility

Motion controllers offer specialized programming languages such as ladder logic, function block, or structured text specifically designed for precise motion control tasks, enabling advanced trajectory planning and synchronization. PLCs use versatile but more general-purpose programming environments that handle a broader range of automation processes, including discrete and process control, but may lack the granular motion control capabilities. Your choice depends on whether you need highly flexible, motion-specific programming or a more generalized control system for diverse automation functions.

Performance and Speed Comparison

Motion controllers offer superior performance and faster processing speeds compared to traditional PLCs, making them ideal for high-precision, real-time control tasks in automation. PLCs excel in managing discrete I/O and logic control but may introduce latency in complex motion operations due to slower scan cycles. Your choice should consider the speed requirements and responsiveness needed for precise motion synchronization in applications.

Application Suitability and Use Cases

Motion controllers excel in precision-driven applications such as robotics, CNC machines, and automated assembly lines, where coordinated multi-axis movement and real-time feedback are critical. PLCs are better suited for general industrial automation tasks involving logic control, such as conveyor systems, packaging, and process control, due to their robustness and ease of integration with sensors and actuators. Understanding your specific application requirements helps determine whether a motion controller or a PLC offers the best performance and flexibility for your automation system.

Scalability and Expandability

Motion controllers provide superior scalability and expandability for complex automation tasks, supporting multi-axis control and advanced motion profiling with the ability to integrate additional modules or axes as system requirements grow. Programmable Logic Controllers (PLCs) offer robust scalability for general process control through modular I/O expansion but may face limitations when handling high-precision, high-speed motion control compared to specialized motion controllers. Selecting between motion controllers and PLCs depends on the need for precise motion scalability or broader control system expandability within industrial automation environments.

Cost Implications and Budget Considerations

Motion controllers typically have higher initial costs due to specialized hardware and software, while PLCs offer more affordable entry points for basic automation tasks. Your budget should account for the total cost of ownership, including integration, programming, and maintenance, where motion controllers may incur higher expenses. Choosing between the two depends on the complexity of motion control requirements and long-term operational efficiency.

Reliability and Maintenance Factors

Motion controllers offer enhanced reliability through specialized hardware designed for precise motor control, reducing the risk of mechanical failure and downtime. PLCs provide robust general automation capabilities with easier maintenance due to widespread industry adoption and simpler programming. Your choice depends on whether you prioritize high-precision motion tasks with consistent reliability or versatile automation solutions with straightforward upkeep.

Choosing the Right Solution for Automation Needs

Selecting the right solution for automation depends on the complexity and precision requirements of the application, with Motion Controllers excelling in high-speed, multi-axis coordination and real-time motion profiling. PLCs offer robust versatility and reliability for general process control, handling discrete and analog inputs with strong integration into factory-wide control systems. Evaluating factors such as cycle time, scalability, and communication protocols ensures the optimal balance between performance and cost for specific industrial automation needs.

Motion Controller vs PLC Infographic

libmatt.com

libmatt.com