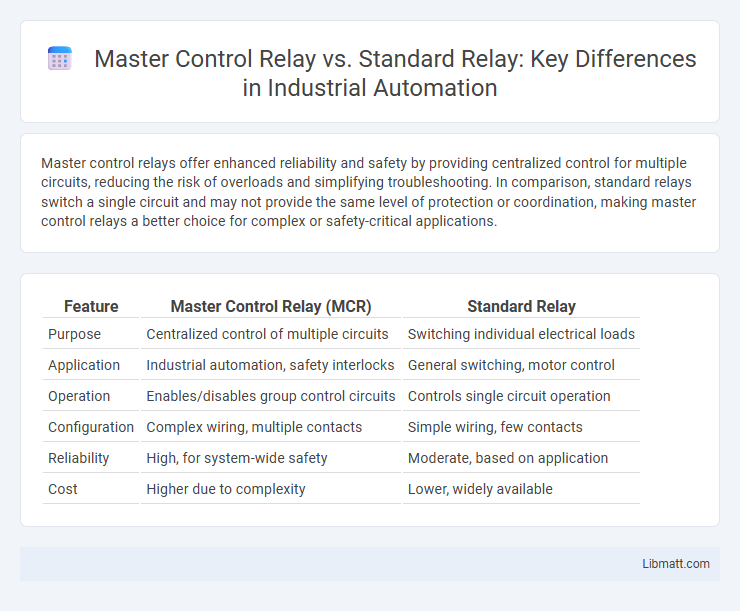

Master control relays offer enhanced reliability and safety by providing centralized control for multiple circuits, reducing the risk of overloads and simplifying troubleshooting. In comparison, standard relays switch a single circuit and may not provide the same level of protection or coordination, making master control relays a better choice for complex or safety-critical applications.

Table of Comparison

| Feature | Master Control Relay (MCR) | Standard Relay |

|---|---|---|

| Purpose | Centralized control of multiple circuits | Switching individual electrical loads |

| Application | Industrial automation, safety interlocks | General switching, motor control |

| Operation | Enables/disables group control circuits | Controls single circuit operation |

| Configuration | Complex wiring, multiple contacts | Simple wiring, few contacts |

| Reliability | High, for system-wide safety | Moderate, based on application |

| Cost | Higher due to complexity | Lower, widely available |

Introduction to Master Control Relay vs Standard Relay

Master control relays are designed to manage multiple control circuits simultaneously, offering enhanced coordination and safety in complex electrical systems. Standard relays typically control a single circuit or function and are used for basic switching tasks. Your choice between a master control relay and a standard relay depends on the complexity and requirements of your control system.

Key Differences Between Master Control Relay and Standard Relay

Master Control Relays (MCR) differ from Standard Relays primarily in their function, with MCRs used to control multiple circuits simultaneously, providing centralized control and safety interlocking in complex automation systems. Standard Relays typically switch a single circuit on or off based on an input signal, offering simpler and individual control. The enhanced complexity and coordination capabilities of MCRs make them essential for applications requiring synchronized operations and fail-safe conditions.

Working Principle of Master Control Relay

A Master Control Relay operates by using a control circuit to energize or de-energize multiple other relays simultaneously, ensuring centralized control of complex electrical systems. Unlike standard relays that typically switch a single circuit on or off, the master relay coordinates multiple outputs based on specific input conditions, enhancing system reliability and automation. Understanding this working principle allows your control panels to manage intricate operations efficiently and reduce the risk of overload or fault conditions.

Working Principle of Standard Relay

A standard relay operates by using an electromagnet to mechanically switch electrical contacts in response to a control signal, allowing low-power circuits to control high-power loads. When current flows through the relay coil, the generated magnetic field attracts a movable armature that opens or closes the contacts, enabling the desired electrical connection. Understanding the working principle of a standard relay helps you design reliable circuits for automation and protection applications.

Applications of Master Control Relays

Master Control Relays (MCRs) are extensively used in industrial automation systems to coordinate and manage multiple control signals, enhancing operational safety and reliability. They serve as critical components in emergency shutdown systems, ensuring rapid response and system isolation to prevent equipment damage or hazards. MCRs are also employed in complex machinery where centralized control logic is required to synchronize sequential operations and reduce wiring complexity.

Applications of Standard Relays

Standard relays are widely used in industrial automation, motor control circuits, and lighting systems due to their reliable switching capabilities. These relays handle moderate voltage and current levels, making them ideal for general-purpose applications such as controlling pumps, fans, and other machinery. Your electrical system benefits from the simplicity and cost-effectiveness of standard relays in routine control tasks.

Advantages of Master Control Relays

Master Control Relays offer enhanced reliability and centralized control, reducing wiring complexity and minimizing system downtime compared to Standard Relays. These relays improve safety by providing a single point of control for multiple circuits, streamlining troubleshooting and maintenance processes. Your electrical systems benefit from faster response times and increased coordination when using Master Control Relays.

Benefits and Limitations of Standard Relays

Standard relays offer straightforward, cost-effective switching solutions ideal for low-power and simple control circuits, with quick response times and ease of installation. Their limitations include susceptibility to mechanical wear, contact bounce, and limited ability to handle complex or high-current control tasks compared to Master Control Relays. These constraints make standard relays less suitable for applications requiring enhanced durability, reliability, or integrated safety features present in Master Control Relays.

Selection Criteria: Choosing the Right Relay

Selection criteria for choosing between a Master Control Relay and a Standard Relay include load capacity, switching speed, and control complexity. Master Control Relays are ideal for complex automation systems requiring multiple output controls and high reliability, while Standard Relays suit simpler applications with lower current demands. Consider factors such as coil voltage ratings, contact arrangement, and environmental conditions to ensure optimal performance and longevity.

Conclusion: Master Control Relay vs Standard Relay

Master Control Relays provide centralized control by consolidating multiple relay functions into a single unit, improving system reliability and simplifying wiring compared to Standard Relays. Standard Relays typically handle individual switching tasks, leading to increased component count and potential for wiring errors in complex systems. Choosing Master Control Relays enhances operational efficiency and reduces maintenance complexity in industrial control applications.

Master Control Relay vs Standard Relay Infographic

libmatt.com

libmatt.com