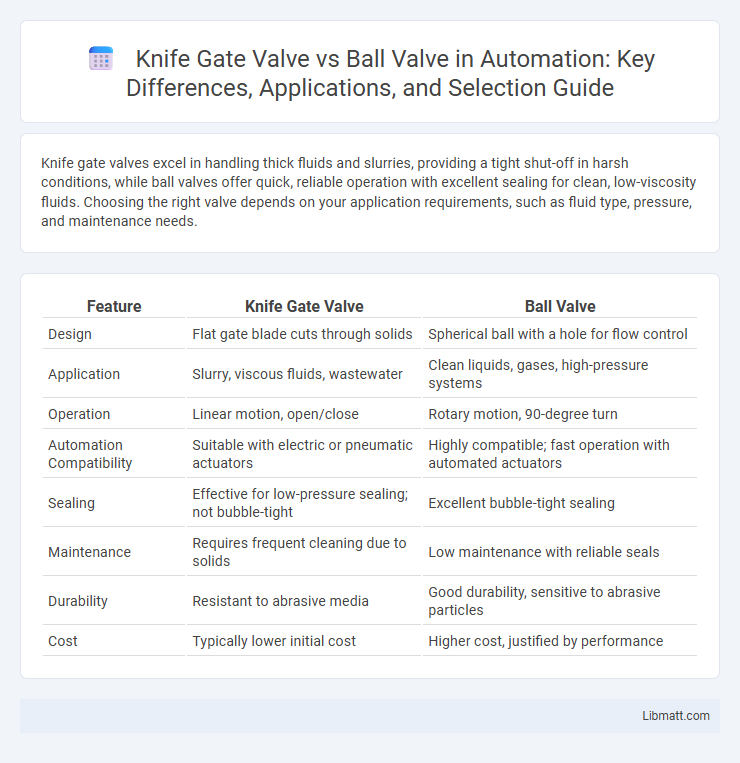

Knife gate valves excel in handling thick fluids and slurries, providing a tight shut-off in harsh conditions, while ball valves offer quick, reliable operation with excellent sealing for clean, low-viscosity fluids. Choosing the right valve depends on your application requirements, such as fluid type, pressure, and maintenance needs.

Table of Comparison

| Feature | Knife Gate Valve | Ball Valve |

|---|---|---|

| Design | Flat gate blade cuts through solids | Spherical ball with a hole for flow control |

| Application | Slurry, viscous fluids, wastewater | Clean liquids, gases, high-pressure systems |

| Operation | Linear motion, open/close | Rotary motion, 90-degree turn |

| Automation Compatibility | Suitable with electric or pneumatic actuators | Highly compatible; fast operation with automated actuators |

| Sealing | Effective for low-pressure sealing; not bubble-tight | Excellent bubble-tight sealing |

| Maintenance | Requires frequent cleaning due to solids | Low maintenance with reliable seals |

| Durability | Resistant to abrasive media | Good durability, sensitive to abrasive particles |

| Cost | Typically lower initial cost | Higher cost, justified by performance |

Introduction to Knife Gate Valves and Ball Valves

Knife gate valves feature a sharp-edged gate designed to cut through thick liquids and solids, making them ideal for sludge, pulp, and wastewater applications. Ball valves use a rotating spherical ball to control flow, providing reliable sealing and quick shutoff for clean or slightly viscous fluids. Your choice depends on the media type and flow control needs, with knife gate valves excelling in slurry handling and ball valves offering durability and precision.

Key Design Differences

Knife gate valves feature a thin, sharp-edged gate that slides vertically to cut through thick fluids and solids, making them ideal for slurry or wastewater applications. Ball valves use a spherical ball with a bore that rotates to control flow, providing tight sealing and quicker operation in clean, high-pressure pipelines. Your choice depends on the flow media and required sealing performance, with knife gate valves suited for abrasive materials and ball valves optimized for precise shutoff and durability.

Operating Mechanism Comparison

Knife gate valves operate using a sharp-edged gate that slides down to cut through thick fluids or slurries, providing minimal resistance and enabling smooth flow control. In contrast, ball valves feature a spherical ball with a bore that rotates 90 degrees to start or stop flow, offering quick operation and tight sealing in high-pressure systems. The knife gate mechanism excels in applications with viscous or abrasive media, while ball valves are preferred for their durability and reliability in clean, high-pressure environments.

Suitability for Specific Applications

Knife gate valves are ideal for handling slurry, viscous fluids, and applications involving thick, abrasive materials due to their sharp-edged gate that cuts through solids. Ball valves provide excellent shutoff capabilities and are best suited for clean liquids and gases in high-pressure systems where quick operation and tight sealing are required. In wastewater treatment, mining, and pulp industries, knife gate valves outperform ball valves, while ball valves dominate in oil and gas, chemical processing, and water distribution for their durability and leak-proof performance.

Flow Control Capabilities

Knife gate valves excel in handling slurry, viscous fluids, and heavy particulate-laden flows due to their sharp-edged gate design, which offers minimal obstruction and precise flow regulation in such demanding applications. Ball valves provide superior flow control for clean, low-viscosity fluids by enabling quick shut-off and excellent sealing through a spherical closure, ensuring minimal pressure drop and consistent flow rate. Your choice depends on the specific fluid characteristics and flow control requirements, as knife gate valves are better for abrasive or thick media, while ball valves deliver high-performance control in standard liquid systems.

Sealing Performance and Leakage Prevention

Knife gate valves provide superior sealing performance in handling slurry, viscous fluids, and solid-laden mediums due to their sharp-edged gate design that cuts through media, minimizing leakage paths. Ball valves offer excellent leakage prevention with a tight, 360-degree sealing surface that provides reliable shut-off for gases and liquids under high pressure. Choosing the right valve depends on your specific application requirements, with knife gate valves suited for aggressive media and ball valves ideal for pressure-tight sealing in clean or low-viscosity fluids.

Maintenance and Lifespan Considerations

Knife gate valves feature simple designs with fewer moving parts, making maintenance straightforward and cost-effective, especially in slurry or viscous fluid applications. Ball valves typically offer longer lifespans due to robust construction and better sealing mechanisms, but they may require more frequent checks and lubrication to prevent wear in high-cycle operations. Your choice should weigh the ease of upkeep against operational demands to maximize valve longevity and reliability.

Material Compatibility and Corrosion Resistance

Knife gate valves are typically constructed from stainless steel or ductile iron with specialized coatings, offering superior performance in handling abrasive slurries and corrosive materials, making them ideal for wastewater and mining applications. Ball valves, often made from stainless steel, brass, or carbon steel, provide excellent corrosion resistance in clean, non-abrasive fluid systems and are commonly used in oil, gas, and chemical industries. Material compatibility in knife gate valves emphasizes abrasion resistance, while ball valves prioritize sealing capability and chemical resistance in diverse media.

Cost Factors and Installation Requirements

Knife gate valves generally offer lower initial costs compared to ball valves due to simpler design and fewer components. Installation of knife gate valves often requires more space and alignment precision because of their linear motion, while ball valves typically have compact installation footprints and easier integration with standard piping. Maintenance expenses for knife gate valves can be higher in abrasive applications, whereas ball valves provide more reliable sealing with potentially reduced lifecycle costs.

Choosing the Right Valve for Your System

Knife gate valves excel in handling slurry, viscous fluids, and solids-laden media due to their sharp-edged gate that cuts through thick materials, making them ideal for wastewater and mining applications. Ball valves offer superior sealing and quick operation, providing excellent performance for clean liquids, gases, and high-pressure systems where tight shutoff is critical. Choosing the right valve for your system depends on the type of media, pressure requirements, and maintenance preferences to ensure optimal efficiency and longevity.

Knife Gate Valve vs Ball Valve Infographic

libmatt.com

libmatt.com