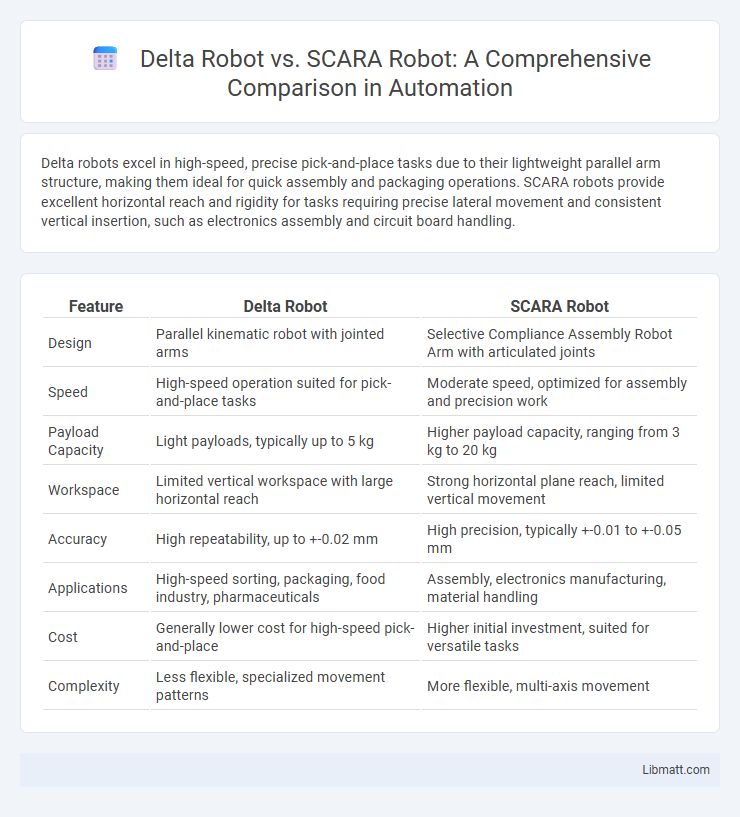

Delta robots excel in high-speed, precise pick-and-place tasks due to their lightweight parallel arm structure, making them ideal for quick assembly and packaging operations. SCARA robots provide excellent horizontal reach and rigidity for tasks requiring precise lateral movement and consistent vertical insertion, such as electronics assembly and circuit board handling.

Table of Comparison

| Feature | Delta Robot | SCARA Robot |

|---|---|---|

| Design | Parallel kinematic robot with jointed arms | Selective Compliance Assembly Robot Arm with articulated joints |

| Speed | High-speed operation suited for pick-and-place tasks | Moderate speed, optimized for assembly and precision work |

| Payload Capacity | Light payloads, typically up to 5 kg | Higher payload capacity, ranging from 3 kg to 20 kg |

| Workspace | Limited vertical workspace with large horizontal reach | Strong horizontal plane reach, limited vertical movement |

| Accuracy | High repeatability, up to +-0.02 mm | High precision, typically +-0.01 to +-0.05 mm |

| Applications | High-speed sorting, packaging, food industry, pharmaceuticals | Assembly, electronics manufacturing, material handling |

| Cost | Generally lower cost for high-speed pick-and-place | Higher initial investment, suited for versatile tasks |

| Complexity | Less flexible, specialized movement patterns | More flexible, multi-axis movement |

Introduction to Delta and SCARA Robots

Delta robots feature a parallel-arm structure designed for high-speed, precision pick-and-place tasks commonly used in packaging, electronics assembly, and pharmaceutical industries. SCARA robots, or Selective Compliance Assembly Robot Arms, boast a rigid vertical axis and flexible horizontal joints ideal for lateral movements, making them suitable for assembly operations, screw driving, and material handling. Both robot types offer distinct advantages in speed, accuracy, and operational range, tailored to specific industrial automation needs.

Structural Design Differences

Delta robots feature a parallel kinematic structure with three arms connected to universal joints at the base, enabling high-speed and precise movement in a lightweight frame. SCARA robots possess a serial arm design with two parallel rotary joints that allow for rigid lateral movements and vertical displacement, ideal for horizontal tasks. The distinct structural configurations influence their respective strengths in speed, payload, and application suitability.

Speed and Precision Comparison

Delta robots excel in high-speed operations with rapid acceleration and deceleration, making them ideal for pick-and-place tasks requiring quick movements. SCARA robots offer superior precision and repeatability, especially in horizontal plane applications where tight tolerances are critical. Your choice depends on whether speed or precision is paramount for your specific automation needs.

Workspace and Reach Capabilities

Delta robots feature a dome-shaped workspace with high-speed, precise movements suited for pick-and-place tasks within a limited vertical range, typically up to 1 meter in height. SCARA robots offer a cylindrical workspace with a larger horizontal reach, often extending beyond 1 meter, enabling flexible handling for assembly and packaging operations. The choice depends on the application's spatial requirements, where Delta excels in rapid, light payload tasks and SCARA provides versatility in reach and multi-axis movement.

Payload Capacity Analysis

Delta robots excel in high-speed applications with payload capacities typically ranging from 0.5 to 5 kg, making them ideal for lightweight assembly and packaging tasks. SCARA robots generally offer higher payload capacities, often between 3 to 20 kg, supporting medium-weight operations such as material handling and machine tending. Your choice depends on whether precision and speed or higher payload capacity are the priority for your automation needs.

Typical Industrial Applications

Delta robots excel in high-speed, precise pick-and-place tasks, commonly used in packaging, pharmaceutical, and electronics assembly industries due to their parallel kinematic design enabling quick, repeatable motions. SCARA robots, with their rigid arm structure and vertical movement capabilities, are preferred for assembly operations, screw driving, and material handling in automotive and consumer electronics manufacturing. Your choice depends on the specific application needs: Delta robots for rapid, lightweight object handling and SCARA robots for precise, horizontal assembly tasks.

Cost and Maintenance Considerations

Delta robots generally have higher initial costs due to their complex parallel arm design and lightweight materials, but require less maintenance because of fewer moving parts. SCARA robots offer a lower upfront investment and simpler mechanical structure, making maintenance easier and more affordable over time. Evaluating your production needs will help determine which robot aligns better with your budget and maintenance capabilities.

Integration and Flexibility

Delta robots excel in high-speed, precise pick-and-place applications with easy integration into existing production lines due to their parallel kinematics design. SCARA robots offer superior flexibility in handling complex assembly tasks, providing versatile horizontal movement and adaptability to various workspaces, which enhances your manufacturing scalability. Choosing between these robots depends on the specific integration requirements and the flexibility needed for your automation processes.

Pros and Cons of Delta Robots

Delta robots excel in high-speed pick-and-place tasks with exceptional precision due to their lightweight parallel arm structure and low inertia. Their main advantages include rapid movement, superior accuracy, and the ability to handle delicate objects, making them ideal for packaging and assembly in electronics and food industries. However, delta robots typically have limited payload capacity and restricted vertical movement range compared to SCARA robots, which can perform more versatile horizontal and vertical operations with heavier loads.

Pros and Cons of SCARA Robots

SCARA robots excel in high-speed, precise horizontal movements, making them ideal for assembly and pick-and-place tasks with compact footprints and cost-effectiveness. Their limited vertical range and rigidity constrain flexibility in 3D space, which can reduce adaptability to complex tasks requiring multi-directional reach. You benefit from SCARA robots when accuracy and speed on a fixed plane are critical, but they may fall short in applications demanding extensive vertical mobility or payload capacity.

Delta Robot vs SCARA Robot Infographic

libmatt.com

libmatt.com