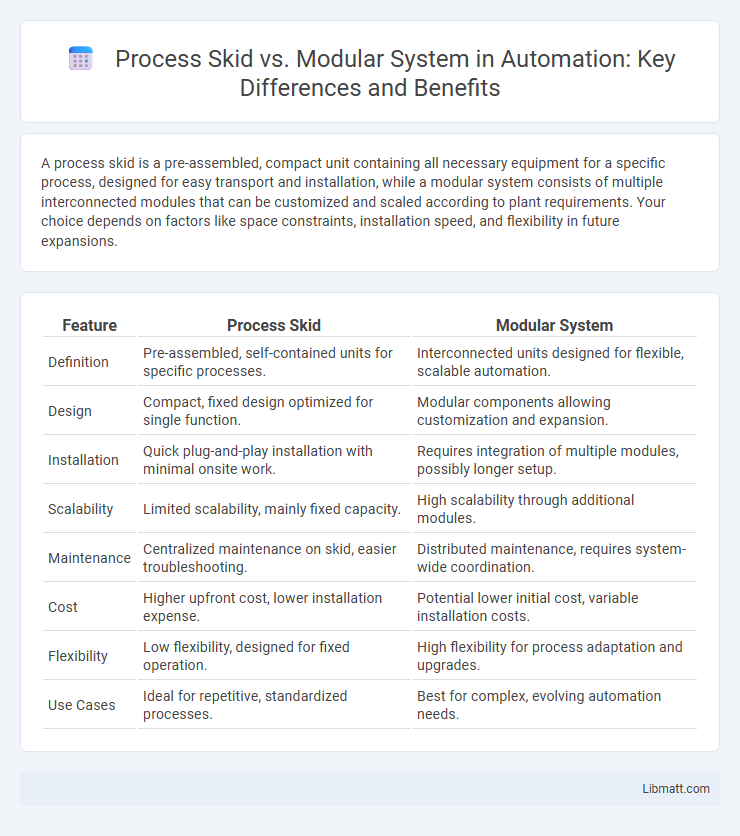

A process skid is a pre-assembled, compact unit containing all necessary equipment for a specific process, designed for easy transport and installation, while a modular system consists of multiple interconnected modules that can be customized and scaled according to plant requirements. Your choice depends on factors like space constraints, installation speed, and flexibility in future expansions.

Table of Comparison

| Feature | Process Skid | Modular System |

|---|---|---|

| Definition | Pre-assembled, self-contained units for specific processes. | Interconnected units designed for flexible, scalable automation. |

| Design | Compact, fixed design optimized for single function. | Modular components allowing customization and expansion. |

| Installation | Quick plug-and-play installation with minimal onsite work. | Requires integration of multiple modules, possibly longer setup. |

| Scalability | Limited scalability, mainly fixed capacity. | High scalability through additional modules. |

| Maintenance | Centralized maintenance on skid, easier troubleshooting. | Distributed maintenance, requires system-wide coordination. |

| Cost | Higher upfront cost, lower installation expense. | Potential lower initial cost, variable installation costs. |

| Flexibility | Low flexibility, designed for fixed operation. | High flexibility for process adaptation and upgrades. |

| Use Cases | Ideal for repetitive, standardized processes. | Best for complex, evolving automation needs. |

Understanding Process Skids: Definition and Core Features

Process skids are pre-assembled, self-contained units designed for specific industrial applications, featuring integrated piping, instrumentation, and control systems optimized for efficient installation and operation. These compact modules simplify plant construction, reduce on-site labor, and ensure consistent quality through factory fabrication. Your project benefits from streamlined commissioning and scalability when utilizing process skid systems in place of traditional modular setups.

What Is a Modular System? Key Characteristics Explained

A modular system is a pre-engineered, factory-fabricated unit designed for easy integration and scalability within industrial processes. Key characteristics include standardized components, simplified installation, and enhanced flexibility to adapt to changing operational requirements. Your choice of a modular system can significantly reduce onsite construction time and improve quality control compared to traditional process skid setups.

Process Skid vs Modular System: Fundamental Differences

Process skid and modular system differ primarily in design scale and installation flexibility. Process skids are compact, self-contained units built for specific processes, allowing quick integration into existing facilities. Modular systems encompass multiple skids or components that form a larger, customizable setup enabling extensive scalability and easier maintenance; your choice depends on project complexity and space constraints.

Design Flexibility: Comparing Adaptability and Customization

Process skids offer high design flexibility with standardized, pre-assembled units that can be quickly adapted for various applications, while modular systems provide superior customization through fully tailored components and layouts tailored specifically to Your project requirements. Modular systems allow seamless integration of individual modules, enabling easier scalability and upgrades compared to the more compact and transport-efficient design of process skids. Both solutions optimize engineering efficiency, but modular systems excel in adaptability when complex or evolving process needs demand precise customization.

Installation and Commissioning: Speed and Efficiency Analysis

Process skid installations offer rapid deployment due to pre-assembled components tested offsite, minimizing onsite assembly and reducing commissioning time by up to 40%. Modular systems provide enhanced scalability and customization but may require extended installation periods because of onsite integration complexities and multiple interconnections. Efficiency gains in process skid installation are particularly notable in industries demanding fast turnaround, such as oil and gas and chemical processing.

Cost Comparison: Evaluating Initial and Long-term Expenses

Process skids typically incur lower initial costs due to standardized, compact designs and factory fabrication, reducing onsite labor expenses. Modular systems, while often involving higher upfront investments, offer long-term savings through easier scalability, simplified maintenance, and reduced downtime. Analyzing total cost of ownership highlights process skids' economic advantage in smaller-scale projects, contrasted with modular systems' benefits in complex, evolving operations.

Space Requirements: Footprint and Layout Considerations

Process skids typically require a compact footprint with all equipment pre-assembled on a single frame, optimizing space utilization and simplifying layout planning. Modular systems offer flexible layout configurations by integrating multiple skids or units, allowing for customizable space allocation based on facility constraints. Your choice between process skid and modular system directly impacts the spatial efficiency and workflow design of your industrial setup.

Maintenance and Scalability: Operational Implications

Process Skids offer easier maintenance due to their pre-assembled, compact design, allowing quicker access to components and reducing downtime. Modular Systems provide superior scalability by enabling the addition or removal of units to match operational demands without extensive reconfiguration. Your choice impacts operational efficiency, with skids favoring streamlined upkeep and modular systems supporting flexible capacity expansion.

Industry Applications: Choosing the Right Solution

Process skids offer compact, pre-assembled units ideal for industries requiring rapid deployment and standardized operations, such as chemical processing and pharmaceuticals. Modular systems provide flexibility and scalability suited for industries like oil and gas or water treatment, where customization and future expansion are critical. Evaluate your specific industry application demands, production volume, and space constraints to determine whether a process skid or modular system best aligns with your operational goals.

Decision Factors: Selecting Between Process Skid and Modular System

When selecting between a process skid and a modular system, key decision factors include space availability, project timeline, and customization needs. Process skids offer compact, pre-assembled units ideal for limited spaces and rapid deployment, while modular systems provide greater flexibility and scalability for complex operations. Your choice should balance efficiency, installation speed, and future expansion requirements to optimize operational performance.

Process Skid vs Modular System Infographic

libmatt.com

libmatt.com