Servo motors provide precise position control and high torque at varying speeds, making them ideal for dynamic applications requiring feedback systems. Stepper motors offer simplicity and reliability with accurate incremental movement, suitable for tasks where cost-effective, open-loop control meets your basic positioning needs.

Table of Comparison

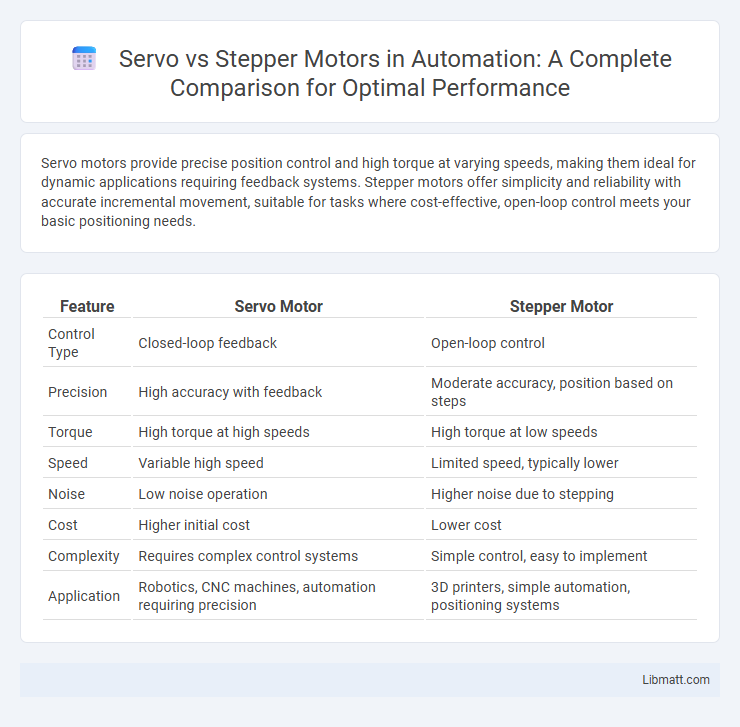

| Feature | Servo Motor | Stepper Motor |

|---|---|---|

| Control Type | Closed-loop feedback | Open-loop control |

| Precision | High accuracy with feedback | Moderate accuracy, position based on steps |

| Torque | High torque at high speeds | High torque at low speeds |

| Speed | Variable high speed | Limited speed, typically lower |

| Noise | Low noise operation | Higher noise due to stepping |

| Cost | Higher initial cost | Lower cost |

| Complexity | Requires complex control systems | Simple control, easy to implement |

| Application | Robotics, CNC machines, automation requiring precision | 3D printers, simple automation, positioning systems |

Introduction: Servo vs Stepper Motors

Servo motors provide precise control of position, speed, and torque through feedback systems, making them ideal for applications requiring high accuracy and dynamic response. Stepper motors operate by dividing a full rotation into discrete steps, offering reliable open-loop control suitable for applications with moderate precision and simpler control requirements. Your choice between servo and stepper motors depends on the specific needs for precision, torque, speed, and control complexity in your project.

Core Differences Between Servo and Stepper Motors

Servo motors provide precise control of angular position, velocity, and acceleration using feedback from encoders, enabling high torque and speed in dynamic applications. Stepper motors move in discrete steps without feedback, offering simpler control and cost-effectiveness for low to medium precision tasks. The core difference lies in servos' closed-loop control system versus steppers' open-loop operation, impacting accuracy, torque consistency, and complexity.

Working Principles of Servo Motors

Servo motors operate using a closed-loop control system that continuously monitors position, velocity, and torque via feedback devices like encoders or resolvers. This feedback enables precise adjustments to the motor's input signals, ensuring accurate and smooth motion control ideal for high-performance applications. Understanding the working principles of servo motors can help you select the right system for tasks requiring dynamic positioning and speed regulation.

Working Principles of Stepper Motors

Stepper motors operate by dividing a full rotation into a series of discrete steps, controlled through energized coils arranged in phases. Each pulse sent to the motor sequentially activates these coils, generating a precise rotational movement without the need for feedback systems. This open-loop control mechanism allows stepper motors to achieve accurate position control in applications such as 3D printers and CNC machines.

Precision and Accuracy Comparison

Servo motors deliver higher precision and accuracy due to their closed-loop feedback system, continuously adjusting position based on real-time data from encoders. Stepper motors operate in open-loop systems, relying on fixed step increments, which can lead to cumulative positioning errors and missed steps under load. The superior resolution and dynamic correction capabilities of servos make them ideal for applications demanding exact control and minimal deviation.

Speed and Torque Performance

Servo motors deliver higher speed and torque performance compared to stepper motors due to their closed-loop control system, which provides precise feedback and continuous adjustment. Stepper motors operate at lower torque levels and speeds but excel in applications requiring accurate positioning without complex feedback mechanisms. High-torque servo motors maintain consistent performance even at high speeds, making them ideal for demanding industrial automation tasks.

Control Systems and Feedback Mechanisms

Servo motors utilize closed-loop control systems with continuous feedback from encoders or resolvers, enabling precise position, speed, and torque adjustments. Stepper motors typically operate with open-loop control, relying on predetermined step sequences without real-time feedback, which can lead to missed steps under load. The integration of feedback mechanisms in servo systems enhances accuracy and dynamic response compared to the simpler control structure of stepper motors.

Typical Applications for Servo Motors

Servo motors are commonly used in robotics, CNC machinery, and automated manufacturing systems where precise control of angular position, velocity, and acceleration is crucial. They excel in applications requiring high torque at varying speeds, such as conveyor belts, industrial automation, and camera autofocus mechanisms. Their closed-loop feedback systems enable accurate and repeatable motion control, making them ideal for complex and dynamic environments.

Typical Applications for Stepper Motors

Stepper motors are commonly used in applications requiring precise positioning and repeatability, such as 3D printers, CNC machines, and robotics. Their ability to move in discrete steps makes them ideal for controlling linear actuators, camera platforms, and automated manufacturing equipment. Your projects benefit from stepper motors' simplicity and reliability when consistent, incremental motion is essential.

Choosing the Right Motor for Your Project

Selecting between a servo and stepper motor hinges on your project's precision, speed, and torque requirements. Servo motors excel in applications demanding high torque and closed-loop control, offering smooth and accurate positioning through feedback systems. Stepper motors provide cost-effective, open-loop control with precise incremental movements, ideal for simpler, low-to-medium torque tasks where cost-efficiency is crucial for your project.

Servo vs Stepper Infographic

libmatt.com

libmatt.com