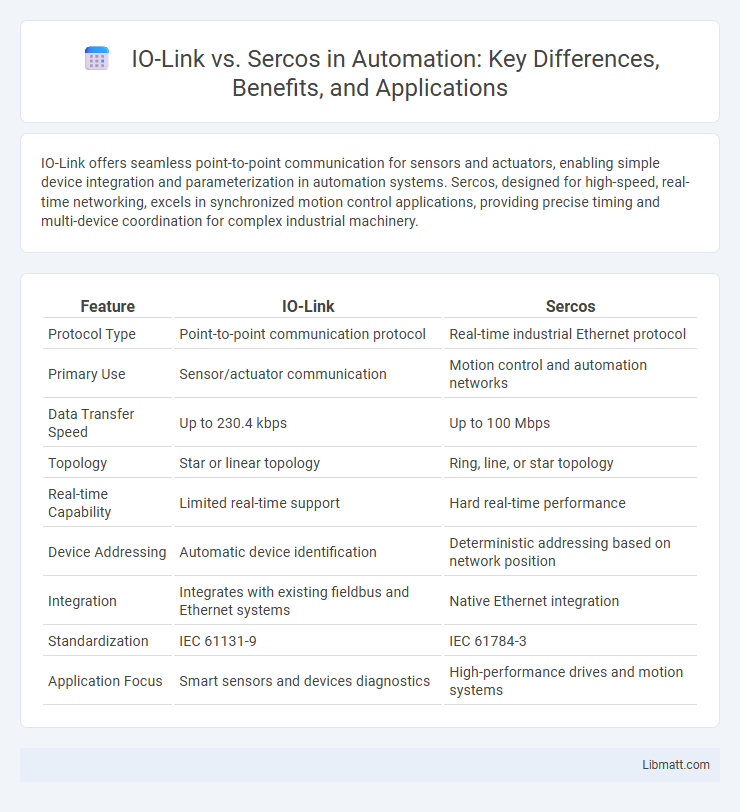

IO-Link offers seamless point-to-point communication for sensors and actuators, enabling simple device integration and parameterization in automation systems. Sercos, designed for high-speed, real-time networking, excels in synchronized motion control applications, providing precise timing and multi-device coordination for complex industrial machinery.

Table of Comparison

| Feature | IO-Link | Sercos |

|---|---|---|

| Protocol Type | Point-to-point communication protocol | Real-time industrial Ethernet protocol |

| Primary Use | Sensor/actuator communication | Motion control and automation networks |

| Data Transfer Speed | Up to 230.4 kbps | Up to 100 Mbps |

| Topology | Star or linear topology | Ring, line, or star topology |

| Real-time Capability | Limited real-time support | Hard real-time performance |

| Device Addressing | Automatic device identification | Deterministic addressing based on network position |

| Integration | Integrates with existing fieldbus and Ethernet systems | Native Ethernet integration |

| Standardization | IEC 61131-9 | IEC 61784-3 |

| Application Focus | Smart sensors and devices diagnostics | High-performance drives and motion systems |

Introduction to IO-Link and Sercos

IO-Link is a point-to-point communication protocol designed for connecting sensors and actuators in industrial automation, offering simple integration and real-time data exchange. Sercos is a high-speed, real-time Ethernet-based protocol primarily used for motion control, providing precise synchronization and deterministic communication in complex automation systems. Your choice between IO-Link and Sercos depends on the need for device-level connectivity versus advanced motion control capabilities.

Overview of IO-Link Technology

IO-Link technology enables seamless communication between sensors and controllers through point-to-point serial connections, enhancing device intelligence and diagnostics in industrial automation. It supports standardized data exchange, easy device integration, and flexible configuration without replacing existing fieldbus systems. Your automation system benefits from improved transparency and reduced downtime due to IO-Link's real-time data monitoring and parameterization capabilities.

Overview of Sercos Protocol

Sercos Protocol is a real-time industrial Ethernet communication standard designed for motion control and automation applications, offering high-speed and deterministic data exchange between controllers and drives. It supports synchronous cyclic data transfer with low latency and is widely used in servo drives, PLCs, and sensors for precise machine control. Understanding Sercos Protocol helps you optimize automation system performance and ensure seamless integration with other industrial networks.

Key Differences Between IO-Link and Sercos

IO-Link is a point-to-point communication protocol primarily used for connecting sensors and actuators, offering simple, cost-effective device integration with standardized parameterization and diagnostics. Sercos, on the other hand, is a real-time, high-speed industrial communication network designed for motion control and automation, supporting synchronized data exchange and deterministic communication across multiple devices. Key differences include IO-Link's focus on device-level communication and easy installation, while Sercos emphasizes high-performance, multimaster networking for complex automation systems.

Communication Architecture Comparison

IO-Link utilizes a point-to-point communication architecture designed for connecting sensors and actuators directly to a master device, enabling simplified system integration and device parameterization. In contrast, Sercos employs a real-time, ring-based Ethernet topology ideal for high-speed, deterministic communication in complex automation networks, supporting multiple devices with synchronized motion control. Your choice between IO-Link and Sercos depends on the scale and real-time performance requirements of your industrial communication system.

Device Compatibility and Integration

IO-Link offers broad device compatibility with standardized interfaces supporting a wide range of sensors and actuators from multiple manufacturers, enabling seamless integration in industrial automation systems. Sercos is primarily designed for high-speed motion control devices and drives, providing real-time communication but with a more specialized device ecosystem. Both protocols enhance integration efficiency, with IO-Link excelling in device diversity and Sercos delivering optimized synchronization for complex motion control applications.

Performance and Speed Analysis

IO-Link offers high-speed point-to-point communication with data rates up to 230.4 kbps, optimized for real-time sensor and actuator integration in Industry 4.0 applications. Sercos, a deterministic Ethernet-based protocol, delivers cycle times as low as 31.25 microseconds, making it ideal for motion control and synchronization in complex automation systems. Performance in speed-sensitive environments favors Sercos for ultra-fast, synchronized data exchange, while IO-Link excels in scalable, device-level communication with simpler infrastructure.

Application Areas and Industry Use Cases

IO-Link excels in sensor and actuator communication within discrete manufacturing, automotive assembly, and packaging industries, enabling plug-and-play device integration and enhanced diagnostic capabilities. Sercos is primarily utilized in motion control applications across robotics, machine tools, and printing presses, offering synchronized real-time communication for complex automation systems. Both protocols optimize automation efficiency but target distinct use cases: IO-Link for versatile device networking and Sercos for high-precision motion control.

Scalability and Future-Proofing

IO-Link offers superior scalability and future-proofing by supporting simple point-to-point communication with easy device integration and automatic parameterization, making it ideal for expanding your automation systems. Sercos provides robust real-time performance for complex motion control but requires more intricate setup and limited device interoperability, which may restrict scalability in fast-evolving applications. Choosing IO-Link ensures seamless integration of new smart sensors and actuators, securing your system's adaptability to future Industry 4.0 advancements.

Choosing the Right Protocol: IO-Link vs Sercos

Selecting between IO-Link and Sercos hinges on application requirements; IO-Link excels in simple device connectivity and sensor-actuator communication with cost-effective point-to-point wiring, while Sercos offers real-time deterministic communication suited for high-performance motion control and complex automation systems. IO-Link supports flexible device integration and seamless diagnostics in smart factories, whereas Sercos provides synchronized multi-axis control and high-speed data transfer for demanding industrial environments. Assessing factors like network topology, data throughput, system complexity, and real-time performance ensures optimal protocol choice for efficient industrial automation.

IO-Link vs Sercos Infographic

libmatt.com

libmatt.com