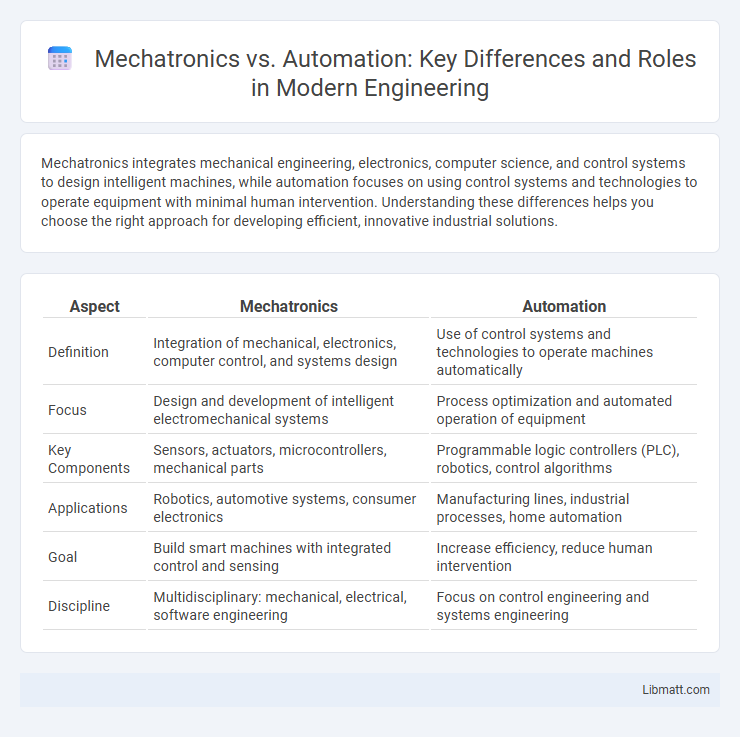

Mechatronics integrates mechanical engineering, electronics, computer science, and control systems to design intelligent machines, while automation focuses on using control systems and technologies to operate equipment with minimal human intervention. Understanding these differences helps you choose the right approach for developing efficient, innovative industrial solutions.

Table of Comparison

| Aspect | Mechatronics | Automation |

|---|---|---|

| Definition | Integration of mechanical, electronics, computer control, and systems design | Use of control systems and technologies to operate machines automatically |

| Focus | Design and development of intelligent electromechanical systems | Process optimization and automated operation of equipment |

| Key Components | Sensors, actuators, microcontrollers, mechanical parts | Programmable logic controllers (PLC), robotics, control algorithms |

| Applications | Robotics, automotive systems, consumer electronics | Manufacturing lines, industrial processes, home automation |

| Goal | Build smart machines with integrated control and sensing | Increase efficiency, reduce human intervention |

| Discipline | Multidisciplinary: mechanical, electrical, software engineering | Focus on control engineering and systems engineering |

Introduction to Mechatronics and Automation

Mechatronics integrates mechanical engineering, electronics, computer science, and control engineering to design and create intelligent systems and products. Automation focuses on using control systems, such as computers or robots, to perform tasks with minimal human intervention, increasing efficiency and precision. Both fields overlap in developing advanced technologies for manufacturing, robotics, and industrial processes, but mechatronics emphasizes multidisciplinary design while automation concentrates on process control and optimization.

Defining Mechatronics: Core Concepts

Mechatronics integrates mechanical engineering, electronics, computer science, and control engineering to design and optimize intelligent systems and products. Core concepts include sensors, actuators, microcontrollers, and real-time control, enabling the development of automated machinery and robotics. Understanding these fundamentals allows you to innovate efficient, multifunctional devices that bridge mechanical and electronic components seamlessly.

Understanding Automation: Key Principles

Automation involves using control systems, such as computers and robots, to perform tasks with minimal human intervention, emphasizing efficiency, precision, and consistency. Key principles include feedback loops, system integration, and process optimization to enhance productivity and reduce errors. Mechatronics combines mechanical engineering, electronics, and computing to design and maintain these automated systems, bridging the gap between hardware and software components.

Major Components of Mechatronics Systems

Mechatronics systems integrate mechanical components, electronic sensors and actuators, and embedded control systems to enable precise automation and intelligent functionality. Key elements include microcontrollers or programmable logic controllers (PLCs) that process data from sensors, enabling real-time decision-making and control of mechanical movements. Your understanding of these major components highlights the synergy between mechanics, electronics, and computing essential for advanced automation solutions.

Core Elements in Automation Technologies

Core elements in automation technologies include sensors, actuators, control systems, and communication networks that enable precise monitoring and control of industrial processes. Mechatronics integrates mechanical, electronic, computer, and control engineering, while automation focuses on the application of these elements for system efficiency and task execution. Your understanding of these core components can enhance system design and optimize performance in automated environments.

Comparing Applications: Mechatronics vs Automation

Mechatronics integrates mechanical engineering, electronics, computer control, and systems design to create intelligent products and processes, often seen in robotics, automotive systems, and aerospace applications. Automation focuses on the use of control systems, such as PLCs and sensors, to operate machinery and processes with minimal human intervention, prevalent in manufacturing, assembly lines, and process industries. While mechatronics designs and develops advanced electromechanical systems, automation aims to optimize operational efficiency and consistency through systematic control.

Key Skills Required in Mechatronics and Automation

Mechatronics requires strong proficiency in mechanical engineering, electronics, computer programming, and system integration to design and maintain intelligent machines. Automation demands expertise in control systems, robotics, software development, and real-time data analysis to optimize industrial processes. Your career success in either field hinges on mastering multidisciplinary skills that blend hardware and software knowledge for efficient system performance.

Industry Trends and Innovations

Mechatronics integrates mechanical engineering, electronics, computer science, and control systems to develop smart machinery, while automation emphasizes the use of control systems and information technologies to reduce human intervention in processes. Industry trends reveal a surge in AI-driven predictive maintenance, IoT-enabled smart factories, and collaborative robots (cobots) enhancing efficiency in both fields. Innovations such as advanced sensor fusion, edge computing, and machine learning algorithms are transforming mechatronics and automation, driving Industry 4.0 and smart manufacturing evolution.

Career Opportunities and Job Prospects

Mechatronics and Automation both offer robust career opportunities in industries such as manufacturing, robotics, and automotive sectors, with mechatronics blending mechanical, electrical, and computer engineering to create intelligent systems. Automation specializes in optimizing processes through control systems and software, leading to increased demand for professionals in process control, systems integration, and industrial engineering. Your choice between these fields can influence job prospects, with mechatronics providing a broader engineering role while automation focuses on specialized control and efficiency roles.

Future Outlook: Mechatronics vs Automation

The future outlook for mechatronics and automation reveals strong growth driven by advancements in AI, robotics, and Industry 4.0 technologies. Mechatronics integrates mechanical, electrical, and software engineering, offering versatile skills applicable in smart manufacturing, autonomous systems, and IoT devices. Your career in automation promises increasing demand for specialists optimizing industrial processes and intelligent control systems, making both fields highly promising but with distinct application focuses.

Mechatronics vs Automation Infographic

libmatt.com

libmatt.com