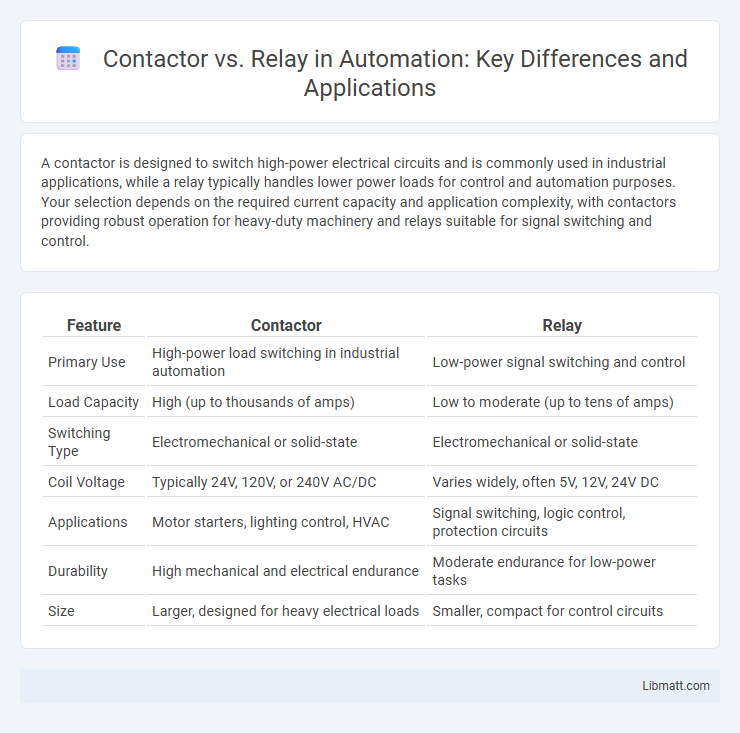

A contactor is designed to switch high-power electrical circuits and is commonly used in industrial applications, while a relay typically handles lower power loads for control and automation purposes. Your selection depends on the required current capacity and application complexity, with contactors providing robust operation for heavy-duty machinery and relays suitable for signal switching and control.

Table of Comparison

| Feature | Contactor | Relay |

|---|---|---|

| Primary Use | High-power load switching in industrial automation | Low-power signal switching and control |

| Load Capacity | High (up to thousands of amps) | Low to moderate (up to tens of amps) |

| Switching Type | Electromechanical or solid-state | Electromechanical or solid-state |

| Coil Voltage | Typically 24V, 120V, or 240V AC/DC | Varies widely, often 5V, 12V, 24V DC |

| Applications | Motor starters, lighting control, HVAC | Signal switching, logic control, protection circuits |

| Durability | High mechanical and electrical endurance | Moderate endurance for low-power tasks |

| Size | Larger, designed for heavy electrical loads | Smaller, compact for control circuits |

Introduction to Contactor vs Relay

Contactor and relay are both electrical switches used to control circuits, but they serve different purposes and operate under different conditions. Contactor is designed to handle higher power loads and is commonly used in industrial motor control, while relay typically controls lower power circuits for signal switching. Understanding the distinction between contactors and relays helps you select the right device for your specific electrical control needs.

Understanding the Roles of Contactors and Relays

Contactors and relays are essential electromagnetic switches used for controlling electrical circuits, with contactors primarily handling high-power loads like motors and lighting systems, while relays manage lower power or signal-level circuits. Understanding their distinct roles helps optimize your electrical system's performance and safety, as contactors offer higher current capacity and durability for industrial applications, whereas relays provide precise control in automation and signal switching. Choosing the right device depends on your specific load requirements, voltage ratings, and operational environment.

Key Differences Between Contactors and Relays

Contactors and relays both serve as electrically operated switches, but contactors are designed to handle higher current loads typically found in industrial motor control applications, while relays are suited for low-current or signal switching. Contactors generally have larger contacts, with ratings often exceeding 20 amps, and include features such as auxiliary contacts for advanced control, unlike most relays. Relays offer faster switching speeds and are typically smaller and used for control circuits where isolation or signal amplification is required.

Construction and Design Comparison

Contactors are typically designed with larger, more robust contacts and a coil to handle high power loads, making them suitable for switching motors and heavy electrical circuits. Relays have smaller contacts and a compact design optimized for signal switching and control applications with lower current ratings. Your choice depends on the electrical demands and physical constraints of your specific application.

Typical Applications of Contactors

Contactors are primarily used in industrial and commercial settings for switching electrical power circuits, such as controlling large motors, lighting systems, heating loads, and electrical panels. Their design supports frequent switching of high-current loads, making them ideal for automation systems, HVAC equipment, and manufacturing machinery. Your choice of contactor ensures reliable operation and extended service life in demanding electrical applications compared to relays, which are better suited for lower power control.

Common Uses of Relays

Relays are commonly used in low-power applications to control circuits with an electrical signal, such as switching on indicator lights, activating alarms, or managing small motors. They provide isolation between the control circuit and the load, making them ideal for sensitive electronic devices. Your automation systems often rely on relays for precise and safe switching operations.

Performance Criteria: Voltage and Current Ratings

Contactor and relay performance criteria differ significantly in voltage and current ratings, with contactors designed to handle higher voltages typically ranging from 24V to 600V AC or DC and current ratings up to several hundred amps, ideal for heavy-duty industrial applications. Relays usually operate at lower voltage and current levels, commonly supporting control circuits from 5V to 240V and currents up to 30 amps, making them suitable for signal switching and low-power loads. Understanding these ratings is crucial for selecting the right component to ensure your electrical system's efficiency and safety.

Advantages and Disadvantages of Each Device

Contactors offer robust performance for switching high electrical loads and provide reliable remote control in industrial applications, but they tend to be larger and consume more power than relays. Relays are compact, cost-effective, and suitable for low-power control circuits, yet they have limited load capacity and shorter mechanical life compared to contactors. Understanding the specific load requirements and control needs is essential for selecting your optimal switching device.

Safety Considerations for Contactors and Relays

Contactors and relays both play critical roles in electrical control systems, but they differ significantly in safety applications. Contactors are designed to handle higher current loads with features like arc suppression and robust insulation, making them safer in high-power environments to prevent electrical faults. Your selection should consider the specific circuit requirements and ensure compliance with safety standards such as IEC and UL certifications to mitigate risks like overheating or short circuits.

Choosing the Right Device for Your Application

Selecting the appropriate device between a contactor and a relay depends primarily on the application's load requirements and switching frequency. Contactors are ideal for high-power circuits, such as motors and industrial equipment, due to their robust construction and ability to handle large currents. Relays suit low-power control circuits, offering faster switching speeds and compact size for electronic and signal-level applications.

Contactor vs Relay Infographic

libmatt.com

libmatt.com