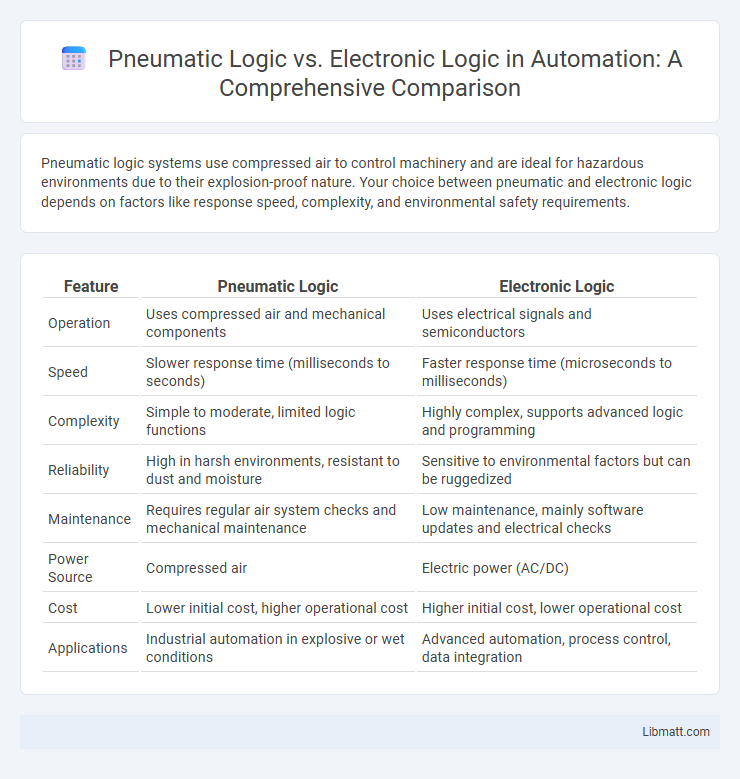

Pneumatic logic systems use compressed air to control machinery and are ideal for hazardous environments due to their explosion-proof nature. Your choice between pneumatic and electronic logic depends on factors like response speed, complexity, and environmental safety requirements.

Table of Comparison

| Feature | Pneumatic Logic | Electronic Logic |

|---|---|---|

| Operation | Uses compressed air and mechanical components | Uses electrical signals and semiconductors |

| Speed | Slower response time (milliseconds to seconds) | Faster response time (microseconds to milliseconds) |

| Complexity | Simple to moderate, limited logic functions | Highly complex, supports advanced logic and programming |

| Reliability | High in harsh environments, resistant to dust and moisture | Sensitive to environmental factors but can be ruggedized |

| Maintenance | Requires regular air system checks and mechanical maintenance | Low maintenance, mainly software updates and electrical checks |

| Power Source | Compressed air | Electric power (AC/DC) |

| Cost | Lower initial cost, higher operational cost | Higher initial cost, lower operational cost |

| Applications | Industrial automation in explosive or wet conditions | Advanced automation, process control, data integration |

Introduction to Pneumatic and Electronic Logic

Pneumatic logic utilizes compressed air to perform control and automation tasks, relying on pressure signals and mechanical components such as valves and actuators. Electronic logic employs electrical signals and semiconductor devices like transistors and integrated circuits to execute logical operations in computing and automation systems. Both technologies serve as fundamental methods for controlling processes, with pneumatic logic favored in hazardous environments and electronic logic prevailing in digital and high-speed applications.

Principles of Pneumatic Logic

Pneumatic logic operates using compressed air to control mechanical systems through valves, actuators, and pressure signals, replicating logical operations such as AND, OR, and NOT without electrical input. This principle relies on the modulation of air pressure to represent binary states, allowing devices to function in environments with high electrical hazards or where electromagnetic interference is present. Understanding these principles can help you choose pneumatic logic systems for applications requiring robust, reliable control in hazardous or industrial settings.

Fundamentals of Electronic Logic

Electronic logic relies on transistors and integrated circuits to perform binary operations using voltage levels representing logical states. It enables high-speed processing and complex computations by manipulating electrical signals through gates like AND, OR, and NOT. This technology forms the foundation for modern digital systems, including computers, microcontrollers, and communication devices.

Key Components in Pneumatic Logic Systems

Key components in pneumatic logic systems include actuators, valves, compressors, and air treatment units designed to control airflow and pressure for mechanical operations. Pneumatic logic utilizes directional control valves, such as 3/2 and 5/2 valves, to create logic functions by directing compressed air through various pathways. Sensors and pneumatic relays play crucial roles in transmitting signals, enabling automation without relying on electronic circuits or software programming.

Main Elements of Electronic Logic Circuits

Electronic logic circuits primarily consist of transistors, resistors, capacitors, and diodes that work together to perform logical operations through voltage levels. Transistors act as switches controlling the flow of current, while resistors and capacitors manage voltage and timing essential for circuit stability. Your understanding of these main elements is crucial when comparing the speed, complexity, and integration capabilities of electronic logic to pneumatic logic systems.

Advantages of Pneumatic Logic

Pneumatic logic systems offer superior durability in harsh environments where electronic components may fail due to moisture, dust, or extreme temperatures. Their intrinsic resistance to electrical interference and sparks makes them ideal for explosive or flammable atmospheres in industrial settings. Furthermore, pneumatic logic systems provide simpler maintenance and longer operational life without the need for complex electronic diagnostic tools.

Benefits of Electronic Logic

Electronic logic provides faster processing speeds and higher precision compared to pneumatic logic systems, enabling more complex and reliable control operations. It offers greater flexibility through programmable configurations and seamless integration with digital networks for advanced automation. Electronic logic also reduces maintenance costs and improves system diagnostics with real-time monitoring and fault detection capabilities.

Limitations and Challenges of Pneumatic Logic

Pneumatic logic systems face limitations such as slower response times, limited scalability, and susceptibility to environmental factors like temperature and humidity, which can affect accuracy and reliability. Maintenance challenges arise from air leaks, contamination, and wear in mechanical components, leading to increased downtime and potential system failures. Your choice should consider these constraints, especially in applications requiring precision and rapid processing.

Drawbacks of Electronic Logic Systems

Electronic logic systems often face drawbacks such as vulnerability to electromagnetic interference (EMI), which can disrupt signal integrity and lead to system malfunctions. They depend heavily on continuous power supply, making them less reliable in power outage scenarios compared to pneumatic logic systems. Moreover, electronic logic components can be sensitive to harsh environmental conditions like extreme temperatures and moisture, limiting their application in certain industrial settings.

Application Scenarios: Choosing Between Pneumatic and Electronic Logic

Pneumatic logic excels in hazardous environments like chemical plants and oil refineries where explosive gases make electronic devices risky due to spark generation. Electronic logic is preferred in high-speed data processing and complex control systems found in automation and robotics, benefiting from precise signal handling and integration with digital networks. Selecting between pneumatic and electronic logic depends on factors such as environmental safety requirements, desired response time, system complexity, and maintenance considerations.

Pneumatic Logic vs Electronic Logic Infographic

libmatt.com

libmatt.com