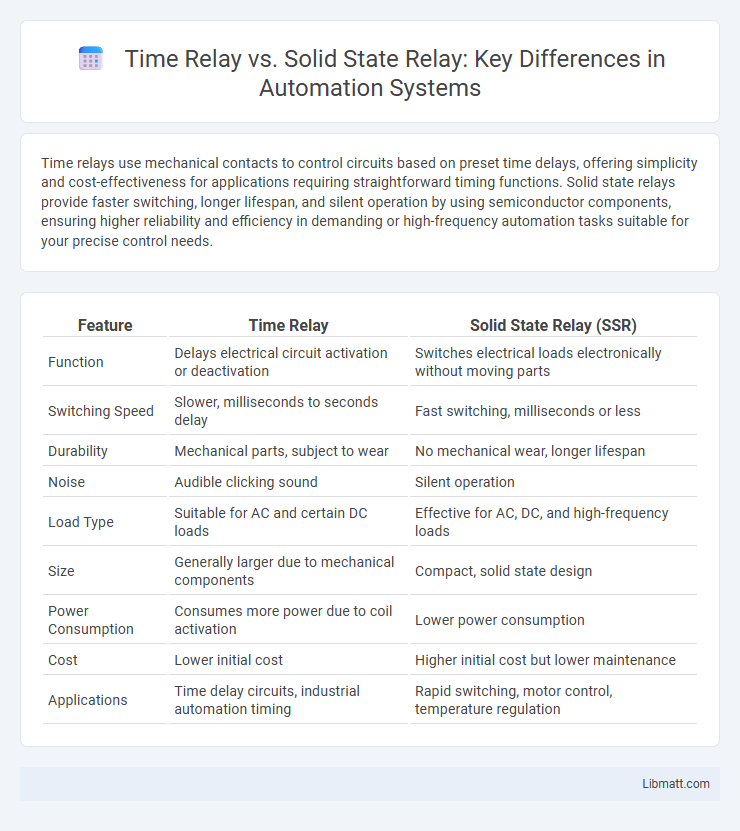

Time relays use mechanical contacts to control circuits based on preset time delays, offering simplicity and cost-effectiveness for applications requiring straightforward timing functions. Solid state relays provide faster switching, longer lifespan, and silent operation by using semiconductor components, ensuring higher reliability and efficiency in demanding or high-frequency automation tasks suitable for your precise control needs.

Table of Comparison

| Feature | Time Relay | Solid State Relay (SSR) |

|---|---|---|

| Function | Delays electrical circuit activation or deactivation | Switches electrical loads electronically without moving parts |

| Switching Speed | Slower, milliseconds to seconds delay | Fast switching, milliseconds or less |

| Durability | Mechanical parts, subject to wear | No mechanical wear, longer lifespan |

| Noise | Audible clicking sound | Silent operation |

| Load Type | Suitable for AC and certain DC loads | Effective for AC, DC, and high-frequency loads |

| Size | Generally larger due to mechanical components | Compact, solid state design |

| Power Consumption | Consumes more power due to coil activation | Lower power consumption |

| Cost | Lower initial cost | Higher initial cost but lower maintenance |

| Applications | Time delay circuits, industrial automation timing | Rapid switching, motor control, temperature regulation |

Introduction to Time Relay and Solid State Relay

Time relays are electromechanical or electronic devices designed to control circuits based on preset time intervals, commonly used in automation to delay or extend operations. Solid State Relays (SSRs) employ semiconductor components like thyristors or triacs to switch loads silently and rapidly without moving parts, ensuring high reliability and longer lifespan. Both relays serve critical roles in controlling electrical circuits, with time relays emphasizing timed control and SSRs offering fast, durable switching solutions.

Key Functions of Time Relays

Time relays control the timing of electrical circuits by delaying the activation or deactivation of connected devices, ensuring precise operation sequences in automation systems. They are essential for functions such as interval timing, cyclic timing, and time delay on energization or de-energization, providing accurate and adjustable control over processes. Your application can benefit from time relays when you need reliable, programmable timing control that solid state relays alone cannot offer.

Core Features of Solid State Relays

Solid State Relays (SSRs) feature semiconductor components that provide fast switching speeds and long operational life without mechanical wear. They offer silent operation, high resistance to shock and vibration, and improved reliability in harsh environments compared to electromagnetic Time Relays. SSRs support zero-cross switching for AC loads, minimizing electrical noise and providing precise control in automated systems.

Working Principles: Time Relay vs Solid State Relay

Time relays operate based on mechanical or electronic timing mechanisms that delay the switching action, using components like coils and springs or integrated circuits to control the on/off intervals. Solid state relays (SSRs) function through semiconductor devices such as thyristors, triacs, or transistors, enabling fast, silent switching without moving parts by controlling electrical signals electronically. The key difference lies in time relays providing programmable time delays through electromechanical or electronic means, while solid state relays offer immediate switching via semiconductor control.

Performance and Response Time Comparison

Time relays operate using electromechanical components, resulting in slower response times typically in the range of milliseconds to seconds, which may limit their use in high-speed switching applications. Solid state relays (SSRs) leverage semiconductor devices, providing significantly faster response times often in microseconds, enabling superior performance in precision timing and rapid switching scenarios. Your choice should consider the required switching speed and durability, with SSRs excelling in applications demanding high performance and quick response.

Durability and Reliability Factors

Time relays typically offer mechanical components that can wear out over time, reducing their durability compared to solid state relays, which have no moving parts and thus provide longer operational life and higher reliability. Solid state relays withstand frequent switching and harsh environmental conditions better, minimizing failure rates and maintenance requirements. Your choice should consider the specific application's duty cycle and environmental stress to ensure optimal durability and reliability performance.

Application Areas for Time Relays

Time relays are essential in automation systems, controlling delayed operations in machinery, lighting, and HVAC systems where precise timing sequences are crucial. These relays are widely used in industrial processes, conveyor systems, and motor control applications to ensure smooth and safe operation. Your choice of a time relay can enhance equipment efficiency and prevent damage by accurately managing operation intervals.

Industrial Uses of Solid State Relays

Solid state relays are widely used in industrial automation for precise control of heating elements, motor speeds, and lighting systems due to their fast switching capabilities and long lifespan. They provide enhanced reliability and reduced electromagnetic interference compared to mechanical relays, making them ideal for high-frequency operations and harsh environments. Industries such as manufacturing, packaging, and process control heavily rely on solid state relays to improve system efficiency and minimize maintenance costs.

Cost-Effectiveness and Maintenance Analysis

Time relays generally offer higher cost-effectiveness for simple timing applications due to their lower initial price and ease of repair, reducing your overall maintenance expenses. Solid state relays, while typically more expensive upfront, provide long-term savings through increased durability, faster switching times, and virtually maintenance-free operation, minimizing downtime and replacement costs. Choosing between them depends on your specific application requirements, budget constraints, and maintenance capabilities.

Choosing the Right Relay: Which One to Use?

When choosing the right relay for your application, consider that time relays excel in controlling delays and sequencing operations, providing precise timing functions essential for automation processes. Solid state relays offer high-speed switching, durability, and noise-free operation, making them ideal for environments requiring silent and rapid control. Your decision should balance the need for timing accuracy versus switching speed and reliability to optimize system performance.

Time Relay vs Solid State Relay Infographic

libmatt.com

libmatt.com