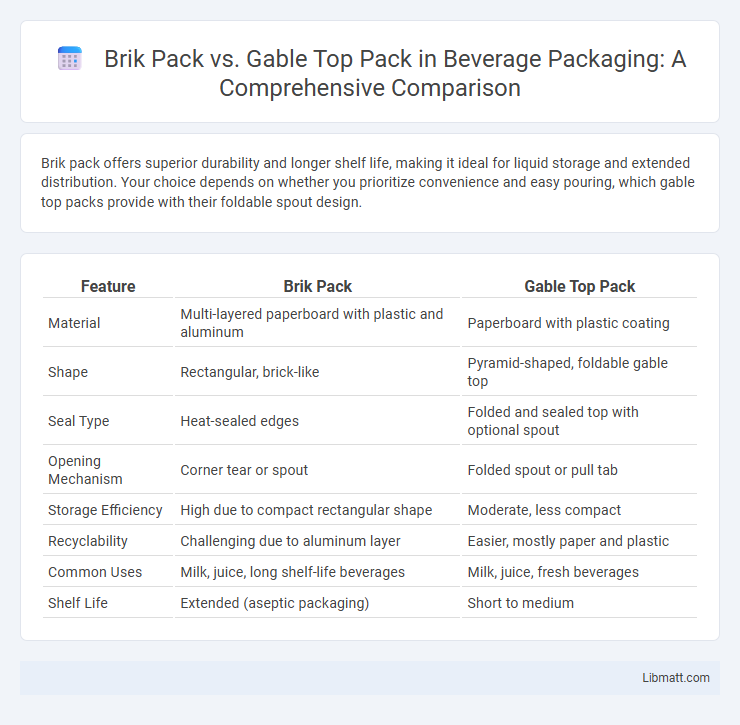

Brik pack offers superior durability and longer shelf life, making it ideal for liquid storage and extended distribution. Your choice depends on whether you prioritize convenience and easy pouring, which gable top packs provide with their foldable spout design.

Table of Comparison

| Feature | Brik Pack | Gable Top Pack |

|---|---|---|

| Material | Multi-layered paperboard with plastic and aluminum | Paperboard with plastic coating |

| Shape | Rectangular, brick-like | Pyramid-shaped, foldable gable top |

| Seal Type | Heat-sealed edges | Folded and sealed top with optional spout |

| Opening Mechanism | Corner tear or spout | Folded spout or pull tab |

| Storage Efficiency | High due to compact rectangular shape | Moderate, less compact |

| Recyclability | Challenging due to aluminum layer | Easier, mostly paper and plastic |

| Common Uses | Milk, juice, long shelf-life beverages | Milk, juice, fresh beverages |

| Shelf Life | Extended (aseptic packaging) | Short to medium |

Introduction to Brik Pack and Gable Top Pack

Brik Pack and Gable Top Pack are popular liquid packaging solutions designed for beverages like milk and juice. Brik Pack features a rectangular, tetrahedral shape that maximizes space efficiency and shelf stability. Your choice between these options depends on factors such as portability, storage, and product preservation needs.

Historical Overview of Beverage Packaging

Brik pack and gable top pack represent two significant innovations in beverage packaging with distinct historical developments. Brik pack, introduced by Tetra Pak in the 1960s, revolutionized liquid packaging through aseptic technology, enabling long shelf life without refrigeration. Your choice between these formats depends on factors like storage, distribution, and consumer convenience rooted in their pioneering roles in beverage packaging evolution.

Structural Design: Brik Pack vs Gable Top Pack

Brik Pack features a rectangular, aseptic carton with a uniform shape that maximizes storage efficiency and stacking stability, making it ideal for bulk liquid packaging. Gable Top Pack incorporates a distinctive peaked top design that facilitates easy pouring and resealing while providing structural rigidity to withstand pressure changes. Your choice between these packs depends on balancing storage optimization with user-friendly access and product protection.

Material Composition and Sustainability

Brik pack containers are primarily made from multiple layers of paperboard, polyethylene, and aluminum foil, offering robust protection and recyclability when facilities exist. Gable top packs use mainly paperboard with a coating of polyethylene, making them lightweight and easily recyclable in standard programs. Understanding your packaging needs helps choose between Brik pack's enhanced barrier properties or the gable top's simpler material composition for sustainability goals.

Manufacturing Process Differences

Brik pack and gable top pack differ significantly in their manufacturing processes, with Brik packs utilizing aseptic filling technology to seal multi-layered packaging materials under sterile conditions, ensuring extended shelf life without refrigeration. Gable top packs, often used for milk and juice, employ a form-fill-seal process with a simpler forming mechanism and require refrigeration, relying on heat sealing of a single-layer or multi-layer laminate. Your choice depends on production scale, product shelf life requirements, and packaging machinery compatibility.

Shelf Life and Product Protection

Brik pack provides superior shelf life due to its multi-layer barrier technology that effectively protects products from light, oxygen, and moisture, extending freshness without refrigeration. Gable top packs offer good protection but typically have a shorter shelf life as they are more vulnerable to external factors like air exposure after opening. The enhanced sealing and material composition of Brik packs make them ideal for long-term storage of liquid and perishable goods.

Cost Comparison and Economic Impact

Brik pack cartons typically offer lower production costs due to their streamlined design and efficient use of materials, making them more cost-effective for large-scale beverage packaging. Gable top packs incur higher manufacturing and machinery expenses but provide superior ease of use and consumer appeal, which can enhance product value and brand differentiation. Economically, the choice between Brik pack and gable top packs influences supply chain logistics, waste management, and market positioning, directly impacting overall profitability and sustainability strategies.

Consumer Convenience and Usability

Brik pack cartons offer superior consumer convenience with their lightweight design and resealable options, making them ideal for on-the-go use and easy storage. Gable top packs provide straightforward usability through simple open-and-pour features, commonly preferred for products like milk and juice. Both packaging types enhance usability, but Brik packs excel in portability and resealability, while gable tops focus on ease of access and pouring control.

Branding and Shelf Appeal

Brik pack offers a sleek, rectangular shape that maximizes branding visibility with large, flat surfaces ideal for vibrant, high-resolution graphics, enhancing your product's shelf appeal. Gable top pack features a distinctive, peaked design that stands out through its unique silhouette and traditional presentation, often evoking a nostalgic or artisanal feel. Both packaging styles provide strong branding potential, but Brik pack's modern aesthetic typically attracts consumers seeking contemporary, premium products.

Market Trends and Future Prospects

Brik pack and gable top pack show distinct market trends, with Brik pack gaining traction for its superior shelf life and convenience in single-serve packaging, appealing to on-the-go consumers. The gable top pack retains strong demand in traditional dairy and juice sectors due to its recyclability and ease of pouring, aligning with sustainability goals. Your choice between these packaging types should consider evolving consumer preferences and regulatory shifts favoring eco-friendly materials and convenience.

Brik pack vs gable top pack Infographic

libmatt.com

libmatt.com