Cement bulk carriers transport dry cement in large volumes using specialized compartments, ensuring efficient handling and minimal contamination during shipping. Cement tankers, on the other hand, deliver liquid or slurry cement directly to construction sites, allowing your project to receive material in a ready-to-use form.

Table of Comparison

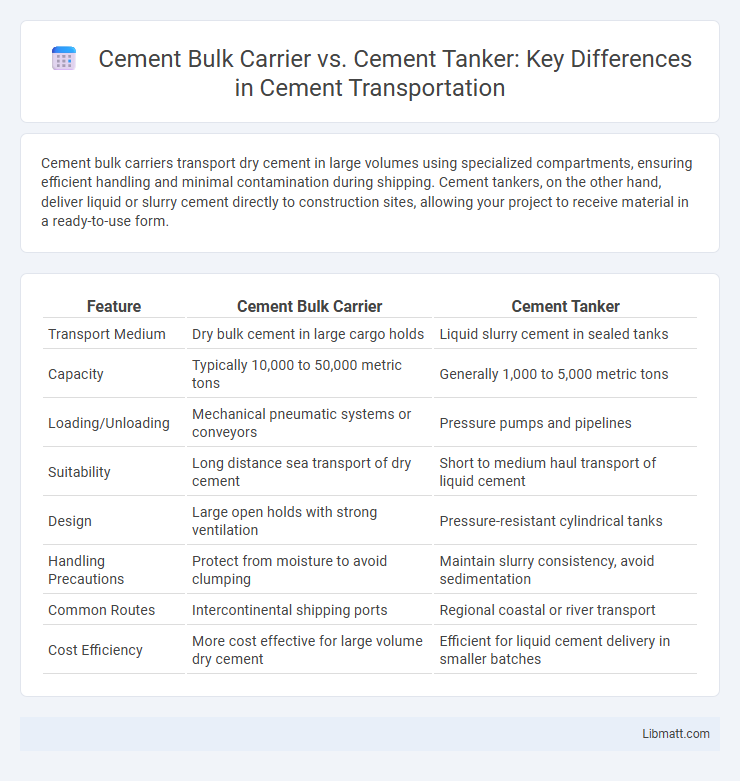

| Feature | Cement Bulk Carrier | Cement Tanker |

|---|---|---|

| Transport Medium | Dry bulk cement in large cargo holds | Liquid slurry cement in sealed tanks |

| Capacity | Typically 10,000 to 50,000 metric tons | Generally 1,000 to 5,000 metric tons |

| Loading/Unloading | Mechanical pneumatic systems or conveyors | Pressure pumps and pipelines |

| Suitability | Long distance sea transport of dry cement | Short to medium haul transport of liquid cement |

| Design | Large open holds with strong ventilation | Pressure-resistant cylindrical tanks |

| Handling Precautions | Protect from moisture to avoid clumping | Maintain slurry consistency, avoid sedimentation |

| Common Routes | Intercontinental shipping ports | Regional coastal or river transport |

| Cost Efficiency | More cost effective for large volume dry cement | Efficient for liquid cement delivery in smaller batches |

Introduction to Cement Bulk Carrier and Cement Tanker

Cement bulk carriers are specialized cargo ships designed to transport large quantities of dry bulk cement, utilizing airtight compartments to prevent moisture contamination and maintain product quality. Cement tankers, on the other hand, are road or rail vehicles equipped with pressurized tanks specifically engineered to deliver powdered cement directly to construction sites or storage facilities. Both modes play crucial roles in the cement supply chain by ensuring efficient, moisture-free transportation tailored to different logistical needs.

Defining Cement Bulk Carrier

A Cement Bulk Carrier is a specialized ship designed to transport powdered cement in large, sealed compartments to prevent moisture contamination during sea transit. Unlike a Cement Tanker, which carries liquid cement slurry in pressurized tanks, the bulk carrier focuses on dry bulk handling with efficient loading and unloading systems. These vessels feature pneumatic systems that maintain the cement's integrity and facilitate rapid discharge at port facilities.

Understanding Cement Tanker

Cement tankers are specialized vessels designed for transporting dry bulk cement in sealed compartments to prevent moisture contamination. Unlike cement bulk carriers, which carry loose bulk cargo in large holds, cement tankers use pressurized systems to unload the powder efficiently. Your selection between these vessels should consider cargo protection and unloading efficiency for optimal cement transport.

Key Differences Between Cement Bulk Carriers and Cement Tankers

Cement bulk carriers are designed primarily for transporting large quantities of dry bulk cement using pneumatic systems, whereas cement tankers transport liquid or slurry cement mixtures in sealed tanks to prevent contamination. The structural design of bulk carriers includes specialized compartments and air pressure systems for unloading dry cement, contrasting with the sealed, pressurized tanks in cement tankers ideal for liquid transport. Operational efficiency varies as bulk carriers cater to dry cement logistics, while tankers are optimized for delivering ready-to-use cement slurry directly to construction sites.

Capacity Comparison: Bulk Carrier vs Tanker

Cement bulk carriers typically offer larger capacity than cement tankers, with bulk carriers able to transport between 10,000 to 50,000 tons of dry cement in a single voyage. Cement tankers usually carry smaller volumes, around 15 to 30 tons of liquid or powdered cement per trip, ideal for short-distance or smaller delivery needs. Your choice depends on the required volume and delivery method, with bulk carriers better suited for large-scale industrial projects and tankers optimized for localized distribution.

Loading and Unloading Mechanisms

Cement bulk carriers utilize pneumatic systems with blowers and compressors to load dry cement powder through airtight pipelines, ensuring contamination-free transfer. Unloading in bulk carriers relies on reverse pneumatic suction or pressure mechanisms that convey cement directly into storage silos with minimal spillage. Cement tankers employ pressurized tanks to load liquid cement slurry using pumps, and unload it through gravity flow combined with pressurized air or mechanical pumps for efficient discharge.

Efficiency and Transportation Costs

Cement bulk carriers offer high efficiency for large-scale cement transport due to their greater capacity and bulk handling systems, significantly lowering transportation costs per ton compared to cement tankers. Cement tankers, while providing more flexibility and suitability for smaller deliveries or distant locations, generally incur higher costs per unit because of frequent loading and unloading operations. Choosing between these options depends on your delivery volume and distance, balancing overall efficiency against transportation expenses.

Safety Features and Regulations

Cement Bulk Carriers and Cement Tankers must comply with strict safety features and regulations to ensure secure transport of powdered cement. Bulk carriers are equipped with reinforced cargo holds and advanced ventilation systems to prevent dust explosions, while tankers utilize pressurized tanks with anti-corrosion coatings and precise pressure monitoring devices. Your choice between these options should consider adherence to international maritime safety standards such as SOLAS and MARPOL, which govern operational safety, environmental protection, and handling procedures for hazardous materials.

Industry Applications and Use Cases

Cement bulk carriers and cement tankers serve distinct roles in transporting cement for construction and industrial projects. Bulk carriers are designed for large-scale shipments of dry bulk cement to ports, where it can be stored or transported further, making them ideal for long-distance and international logistics. Cement tankers, on the other hand, are specialized for on-site delivery of bulk powder via pneumatic systems, ensuring efficient and dust-free transfer directly to your construction site or processing plant.

Choosing the Right Solution for Cement Transport

Cement Bulk Carriers provide cost-effective, large-volume transport ideal for long-distance shipping of dry bulk cement, ensuring minimal contamination and moisture exposure. Cement Tankers offer specialized solutions for shorter routes or smaller quantities, delivering liquid or slurry cement directly to construction sites with ease and precision. Your choice depends on shipment size, distance, and handling requirements to optimize efficiency and maintain cement quality.

Cement Bulk Carrier vs Cement Tanker Infographic

libmatt.com

libmatt.com