Alkali content refers to the total amount of alkali metals, such as sodium and potassium, present in a material, while alkali equivalent is a calculated value expressing the combined effect of all alkalis as a standardized measure, often used in chemical analyses and material characterization. Understanding the difference helps you accurately interpret chemical compositions and their impact on processes like cement hydration and corrosion resistance.

Table of Comparison

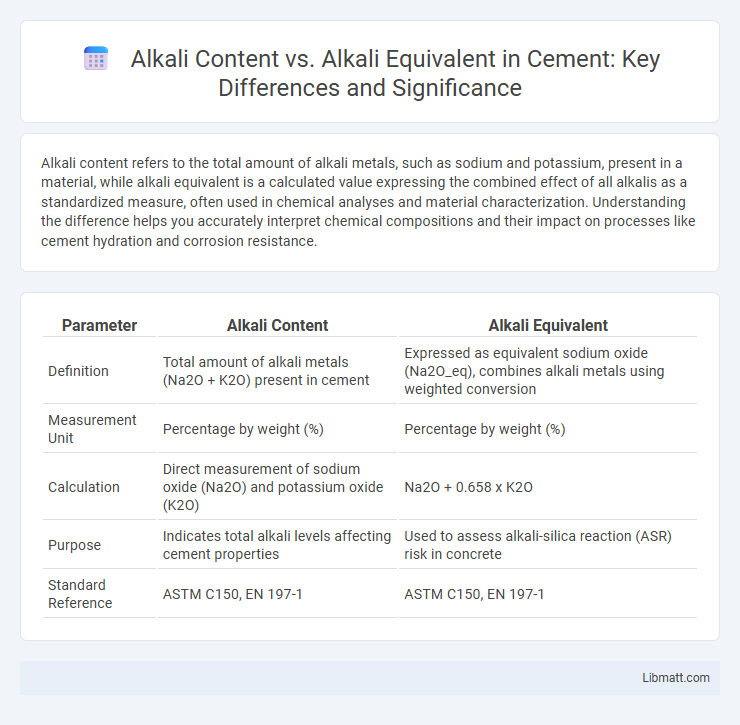

| Parameter | Alkali Content | Alkali Equivalent |

|---|---|---|

| Definition | Total amount of alkali metals (Na2O + K2O) present in cement | Expressed as equivalent sodium oxide (Na2O_eq), combines alkali metals using weighted conversion |

| Measurement Unit | Percentage by weight (%) | Percentage by weight (%) |

| Calculation | Direct measurement of sodium oxide (Na2O) and potassium oxide (K2O) | Na2O + 0.658 x K2O |

| Purpose | Indicates total alkali levels affecting cement properties | Used to assess alkali-silica reaction (ASR) risk in concrete |

| Standard Reference | ASTM C150, EN 197-1 | ASTM C150, EN 197-1 |

Introduction to Alkali Content and Alkali Equivalent

Alkali content refers to the total amount of alkali metals, primarily sodium and potassium, present in a material, typically expressed as a percentage of the sample's weight. Alkali equivalent, often used in cement chemistry, quantifies the combined effect of these alkalis on cement reactivity, influencing durability and susceptibility to alkali-silica reaction (ASR). Understanding the distinction and interplay between alkali content and alkali equivalent is essential for optimizing material performance and preventing long-term structural damage.

Defining Alkali Content

Alkali content refers to the total concentration of alkali metals, primarily sodium (Na) and potassium (K), present in a material or chemical compound. Alkali equivalent specifically quantifies this concentration by converting all alkali metals into an equivalent amount of sodium oxide (Na2O) for standardized comparison. Understanding alkali content is crucial in industries like cement manufacturing, where controlling alkali levels affects product quality and chemical reactivity.

Understanding Alkali Equivalent

Alkali equivalent quantifies the total amount of alkali metals expressed as sodium oxide (Na2O) in cement, providing a standardized measure for comparing alkali content across different materials. It accounts for both sodium (Na2O) and potassium oxides (K2O), facilitating the prediction of potential expansion and durability issues in concrete caused by alkali-silica reaction (ASR). Understanding alkali equivalent is crucial for selecting appropriate cement types and mitigating long-term structural damage in concrete construction.

Key Differences: Alkali Content vs Alkali Equivalent

Alkali content refers to the total amount of alkaline substances, such as sodium oxide (Na2O) and potassium oxide (K2O), present in a material, usually expressed as a percentage. Alkali equivalent, on the other hand, standardizes these substances into a single value by converting all alkali oxides into an equivalent amount of sodium oxide, facilitating comparisons and calculations in cement chemistry and concrete performance. The key difference lies in alkali content measuring actual quantities of individual alkalis, while alkali equivalent provides a unified measurement reflecting the combined effect of all alkali oxides.

Measurement Methods for Alkali Content

Alkali content measurement methods primarily involve flame photometry and atomic absorption spectroscopy, which precisely quantify sodium and potassium ions in cement and concrete materials. Alkali equivalent is calculated by summing the alkali oxides (Na2O and K2O) concentrations, often expressed as a percentage relative to the cement weight, using wet chemical analysis for accuracy. Standardized procedures such as ASTM C114 establish protocols for preparing samples and determining alkali content, ensuring consistency and comparability across different testing laboratories.

Calculation of Alkali Equivalent

Alkali Equivalent is a calculated value that quantifies the total alkali content in a material by summing the contributions of alkali metal oxides, typically expressed as sodium oxide (Na2O) equivalents. The calculation considers the weight percentages of alkali oxides such as Na2O and potassium oxide (K2O), converting K2O to its Na2O equivalent using a specific conversion factor (K2O weight % x 1.21). Understanding the Alkali Equivalent allows you to accurately assess the potential reactivity of cementitious materials in alkali-silica reactions by providing a standardized metric of total alkali content.

Importance in Cement and Concrete Industry

Alkali content and alkali equivalent are critical parameters in the cement and concrete industry as they directly influence the durability and performance of concrete. High alkali content in cement can lead to alkali-silica reaction (ASR), causing expansion and cracking, which compromises structural integrity. Understanding and controlling your cement's alkali equivalent is essential to mitigate these risks and ensure the longevity of concrete structures.

Impact on Material Performance and Durability

Alkali content directly influences the chemical stability and durability of construction materials, where higher alkali levels can accelerate degradation processes such as alkali-silica reaction (ASR) in concrete. Alkali equivalent, often expressed as sodium oxide (Na2O) equivalent, provides a standardized measure to evaluate and compare the total alkali effect on material performance, ensuring consistency in quality control. Understanding and controlling your material's alkali equivalent is crucial for enhancing long-term durability and preventing structural failures.

Industry Standards and Requirements

Alkali content and alkali equivalent are critical parameters in industry standards for materials like cement and glass, ensuring consistent chemical composition and performance. Industry standards such as ASTM C150 and ISO 29581 specify limits for alkali content to control efflorescence and alkali-silica reaction, while alkali equivalent provides a normalized measure accounting for different alkali oxides. Your compliance with these requirements guarantees product reliability, durability, and adherence to regulatory specifications in construction and manufacturing sectors.

Selecting the Right Parameter for Quality Control

Alkali content measures the total amount of alkali metals in a sample, while alkali equivalent reflects the combined effect of alkali oxides on chemical reactions or material properties. Selecting the right parameter for quality control depends on the specific industry context; alkali content is preferred for raw material analysis, whereas alkali equivalent provides deeper insight in processes sensitive to alkali reactivity such as glass manufacturing or cement production. Using alkali equivalent allows for more precise control over product performance by accounting for the reactive potential of sodium and potassium oxides combined.

Alkali content vs Alkali equivalent Infographic

libmatt.com

libmatt.com