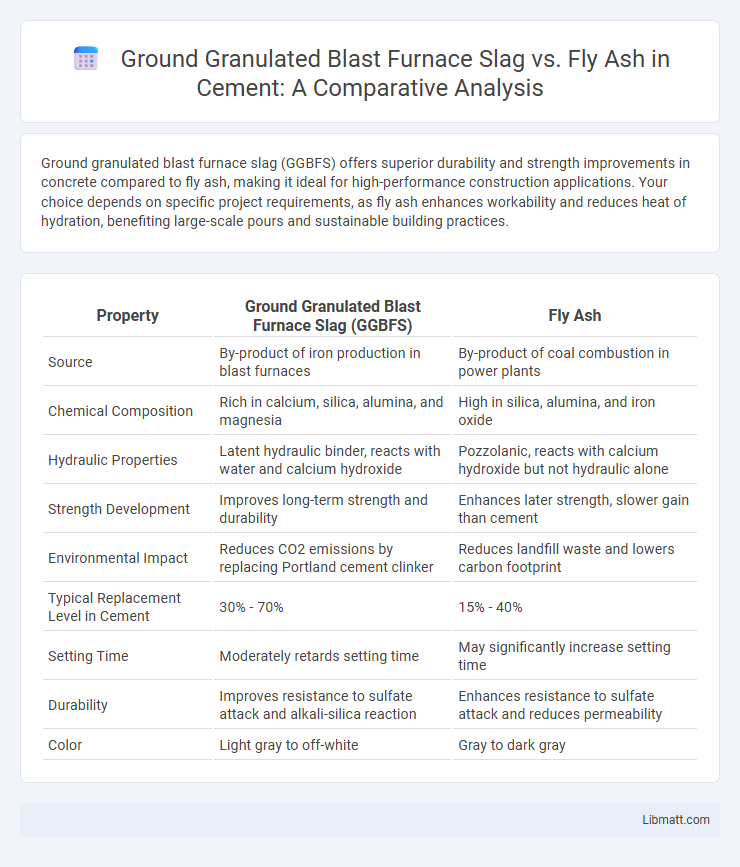

Ground granulated blast furnace slag (GGBFS) offers superior durability and strength improvements in concrete compared to fly ash, making it ideal for high-performance construction applications. Your choice depends on specific project requirements, as fly ash enhances workability and reduces heat of hydration, benefiting large-scale pours and sustainable building practices.

Table of Comparison

| Property | Ground Granulated Blast Furnace Slag (GGBFS) | Fly Ash |

|---|---|---|

| Source | By-product of iron production in blast furnaces | By-product of coal combustion in power plants |

| Chemical Composition | Rich in calcium, silica, alumina, and magnesia | High in silica, alumina, and iron oxide |

| Hydraulic Properties | Latent hydraulic binder, reacts with water and calcium hydroxide | Pozzolanic, reacts with calcium hydroxide but not hydraulic alone |

| Strength Development | Improves long-term strength and durability | Enhances later strength, slower gain than cement |

| Environmental Impact | Reduces CO2 emissions by replacing Portland cement clinker | Reduces landfill waste and lowers carbon footprint |

| Typical Replacement Level in Cement | 30% - 70% | 15% - 40% |

| Setting Time | Moderately retards setting time | May significantly increase setting time |

| Durability | Improves resistance to sulfate attack and alkali-silica reaction | Enhances resistance to sulfate attack and reduces permeability |

| Color | Light gray to off-white | Gray to dark gray |

Introduction to GGBFS and Fly Ash

Ground granulated blast furnace slag (GGBFS) is a byproduct of iron production in blast furnaces, finely ground to enhance cement hydration and strength in concrete. Fly ash, a residue from coal combustion in power plants, improves the durability and workability of concrete when used as a supplementary cementitious material. Understanding the properties and applications of GGBFS and fly ash can help you optimize your concrete mix design for better environmental benefits and performance.

Chemical Composition and Properties

Ground granulated blast furnace slag (GGBFS) primarily contains calcium oxide (CaO), silicon dioxide (SiO2), and aluminum oxide (Al2O3), exhibiting latent hydraulic properties that activate with alkaline environments for cementitious strength. Fly ash, a byproduct of coal combustion, is rich in silica (SiO2) and alumina (Al2O3), with variable calcium content depending on the class type, influencing its pozzolanic reactivity when mixed with lime or cement. Both materials improve concrete durability and reduction of permeability, yet GGBFS tends to enhance early strength development while fly ash contributes to long-term strength gain and workability.

Production Processes of GGBFS and Fly Ash

Ground granulated blast furnace slag (GGBFS) is produced by rapidly cooling molten blast furnace slag from iron production, followed by grinding it into a fine powder. Fly ash forms as a byproduct of coal combustion in power plants, collecting from flue gases and then processed through collection devices like electrostatic precipitators. Your choice between GGBFS and fly ash depends on their distinct production processes, which influence the chemical composition and performance in concrete applications.

Applications in Concrete and Construction

Ground granulated blast furnace slag (GGBFS) enhances concrete durability, reduces permeability, and improves resistance to chemical attacks, making it ideal for infrastructure projects like bridges and marine structures. Fly ash improves workability, reduces heat of hydration, and contributes to sustainable construction practices by replacing cement in concrete mixtures for pavements, high-rise buildings, and mass concrete. Both supplementary cementitious materials optimize concrete performance but differ in chemical composition and environmental benefits, influencing their specific applications in construction.

Environmental Impact and Sustainability

Ground granulated blast furnace slag (GGBFS) significantly reduces CO2 emissions by repurposing by-products from steel production, lowering the need for Portland cement and thereby decreasing carbon footprints in concrete manufacturing. Fly ash, derived from coal combustion, helps reduce landfill waste and energy consumption but is contingent on coal power plants, which face declining trends due to environmental regulations. Both materials enhance sustainability in construction, yet GGBFS offers superior environmental benefits by enabling circular economy practices within the steel industry.

Strength Development and Durability

Ground granulated blast furnace slag (GGBFS) significantly enhances long-term strength development in concrete by accelerating hydration and producing denser microstructures compared to fly ash. Fly ash contributes to moderate strength gain at early ages but excels in improving durability properties such as resistance to sulfate attack and alkali-silica reaction due to its pozzolanic activity. GGBFS-based concretes demonstrate superior durability in aggressive environments, including chloride penetration resistance, making them preferable for marine and industrial applications.

Cost Comparison and Availability

Ground granulated blast furnace slag (GGBFS) often has a higher initial cost than fly ash but can lead to long-term savings due to improved durability and reduced maintenance in concrete applications. Fly ash is generally more affordable and widely available, especially in regions with numerous coal-fired power plants, making it a popular choice for cost-conscious construction projects. Your choice between these supplementary cementitious materials should consider local availability and project budget constraints to optimize overall performance and cost-efficiency.

Standards and Quality Control

Ground granulated blast furnace slag (GGBFS) adheres to standards such as ASTM C989 and EN 15167, ensuring strict quality control related to chemical composition, fineness, and hydration performance. Fly ash quality is regulated by standards like ASTM C618 and EN 450, emphasizing factors including pozzolanic activity, loss on ignition, and particle size distribution. Consistent quality control protocols for both materials are critical for reliable performance in concrete applications and compliance with environmental regulations.

Performance in Different Climates

Ground granulated blast furnace slag (GGBFS) demonstrates superior durability and strength development in both hot and cold climates, providing improved resistance to sulfate attack and reduced permeability. Fly ash enhances workability and long-term strength, performing exceptionally well in moderate to warm climates but may exhibit slower strength gain in cooler environments. Selection between GGBFS and fly ash depends on climate-driven factors such as temperature, moisture exposure, and chemical aggressiveness to optimize concrete performance.

Future Trends in Supplementary Cementitious Materials

Ground granulated blast furnace slag (GGBFS) and fly ash remain key supplementary cementitious materials (SCMs) driving sustainability in the concrete industry due to their ability to reduce carbon emissions and improve durability. Future trends emphasize increased utilization of GGBFS for its higher latent hydraulic properties and adaptability in low-carbon concrete formulations, alongside advanced processing techniques for fly ash to enhance reactivity and performance consistency. Innovations in SCM blending ratios and activation methods are expected to optimize strength development and environmental benefits in next-generation cementitious materials.

Ground granulated blast furnace slag vs Fly ash Infographic

libmatt.com

libmatt.com