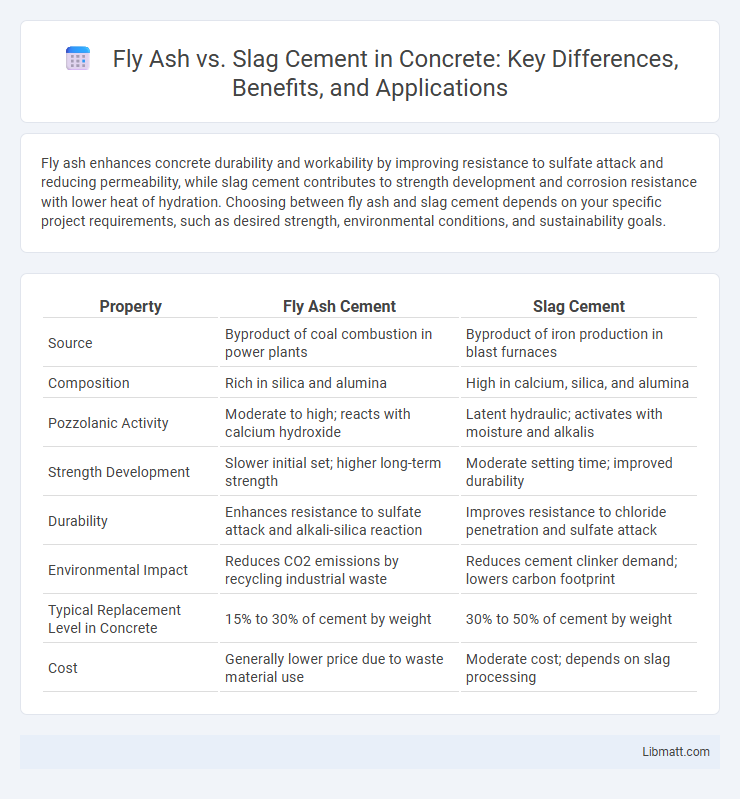

Fly ash enhances concrete durability and workability by improving resistance to sulfate attack and reducing permeability, while slag cement contributes to strength development and corrosion resistance with lower heat of hydration. Choosing between fly ash and slag cement depends on your specific project requirements, such as desired strength, environmental conditions, and sustainability goals.

Table of Comparison

| Property | Fly Ash Cement | Slag Cement |

|---|---|---|

| Source | Byproduct of coal combustion in power plants | Byproduct of iron production in blast furnaces |

| Composition | Rich in silica and alumina | High in calcium, silica, and alumina |

| Pozzolanic Activity | Moderate to high; reacts with calcium hydroxide | Latent hydraulic; activates with moisture and alkalis |

| Strength Development | Slower initial set; higher long-term strength | Moderate setting time; improved durability |

| Durability | Enhances resistance to sulfate attack and alkali-silica reaction | Improves resistance to chloride penetration and sulfate attack |

| Environmental Impact | Reduces CO2 emissions by recycling industrial waste | Reduces cement clinker demand; lowers carbon footprint |

| Typical Replacement Level in Concrete | 15% to 30% of cement by weight | 30% to 50% of cement by weight |

| Cost | Generally lower price due to waste material use | Moderate cost; depends on slag processing |

Introduction to Fly Ash and Slag Cement

Fly ash is a fine powder byproduct from burning pulverized coal in electric power plants, widely used as a supplementary cementitious material to enhance concrete strength and durability. Slag cement, also known as ground granulated blast-furnace slag (GGBFS), is produced by rapidly cooling molten iron slag from blast furnaces, then grinding it into a fine powder to improve concrete's resistance to chemical attack and reduce permeability. Both materials contribute to sustainable construction by recycling industrial byproducts and reducing the carbon footprint of Portland cement.

Chemical Composition: Fly Ash vs Slag Cement

Fly ash primarily consists of silica, alumina, and iron oxide, with variable amounts depending on its source, while slag cement contains higher percentages of calcium oxide, magnesium oxide, and alumina, reflecting its origin from granulated blast furnace slag. The chemical composition of fly ash makes it pozzolanic, reacting with calcium hydroxide to enhance concrete durability, whereas slag cement exhibits latent hydraulic properties, allowing it to hydrate and contribute to strength development independently. Understanding these differences can optimize Your concrete mix design for improved performance and sustainability.

Source and Production Methods

Fly ash is a byproduct of coal combustion in power plants, collected from exhaust gases using electrostatic precipitators, while slag cement is produced by grinding granulated blast furnace slag, a byproduct of iron manufacturing. Fly ash primarily originates from burning pulverized coal, whereas slag cement results from rapidly cooling molten slag with water to form a glassy, granular material. Your choice between these supplementary cementitious materials depends on availability and specific production processes, which influence their physical and chemical properties.

Physical Properties Comparison

Fly ash exhibits finer particle size and spherical shape, enhancing workability and reducing water demand in concrete mixes. Slag cement is denser with angular particles, providing higher early strength and improved durability against chemical attacks. Your choice between fly ash and slag cement impacts concrete's setting time, strength development, and long-term performance based on these physical properties.

Performance in Concrete Mixtures

Fly ash enhances workability, reduces water demand, and improves long-term strength and durability in concrete mixtures, making it suitable for various structural applications. Slag cement contributes to higher early and ultimate strength, better resistance to sulfate attack, and reduced permeability, which improves concrete durability in aggressive environments. Your choice between fly ash and slag cement should consider specific project requirements like strength development and durability needs.

Environmental Impact and Sustainability

Fly ash, a byproduct of coal combustion, reduces landfill waste and lowers carbon emissions when used as a supplementary cementitious material in concrete. Slag cement, derived from blast furnace slag, promotes sustainable construction by recycling industrial waste and decreasing the demand for Portland cement, thus reducing overall greenhouse gas emissions. Both materials improve the environmental footprint of concrete, enhancing durability and resource efficiency in infrastructure projects.

Cost Effectiveness and Availability

Fly ash is generally more cost-effective than slag cement due to its widespread availability as a byproduct of coal combustion in power plants, resulting in lower transportation and procurement costs. Slag cement, derived from the cooling and granulation of molten blast furnace slag, tends to have more variable availability influenced by local steel production volumes, which can increase its price in certain regions. Both materials improve concrete durability and sustainability, but fly ash's broader accessibility often makes it the preferred choice for large-scale, cost-sensitive construction projects.

Workability and Setting Time

Fly ash cement enhances workability due to its spherical particle shape and fineness, improving the mix's flow and reducing water demand. Slag cement also improves workability but tends to increase setting time more significantly compared to fly ash, which provides moderate delay. Both materials influence the hydration process, with slag cement contributing to longer setting times and improved durability in concrete applications.

Durability and Long-Term Strength

Fly ash enhances concrete durability by improving resistance to sulfate attack, reducing permeability, and minimizing alkali-silica reaction, leading to stronger structures over time. Slag cement provides superior long-term strength development and increased resistance to chloride penetration, making it ideal for marine environments and infrastructure exposed to harsh chemicals. Your choice between fly ash and slag cement should consider specific durability requirements and environmental conditions to maximize concrete performance.

Best Practices for Selection and Usage

When selecting between fly ash and slag cement, consider factors like project structural requirements, curing time, and environmental conditions to optimize performance and durability. Fly ash is preferred for enhanced workability and resistance to alkali-silica reaction, while slag cement offers superior strength development and sulfate resistance. Your choice should also account for availability, cost-effectiveness, and compliance with local construction standards to ensure sustainable and efficient concrete mixes.

Fly ash vs Slag cement Infographic

libmatt.com

libmatt.com