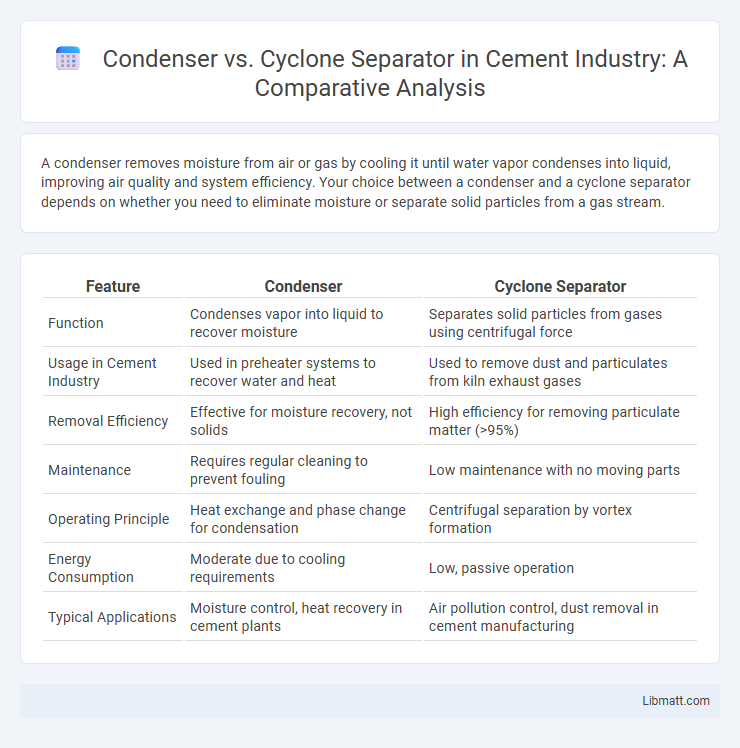

A condenser removes moisture from air or gas by cooling it until water vapor condenses into liquid, improving air quality and system efficiency. Your choice between a condenser and a cyclone separator depends on whether you need to eliminate moisture or separate solid particles from a gas stream.

Table of Comparison

| Feature | Condenser | Cyclone Separator |

|---|---|---|

| Function | Condenses vapor into liquid to recover moisture | Separates solid particles from gases using centrifugal force |

| Usage in Cement Industry | Used in preheater systems to recover water and heat | Used to remove dust and particulates from kiln exhaust gases |

| Removal Efficiency | Effective for moisture recovery, not solids | High efficiency for removing particulate matter (>95%) |

| Maintenance | Requires regular cleaning to prevent fouling | Low maintenance with no moving parts |

| Operating Principle | Heat exchange and phase change for condensation | Centrifugal separation by vortex formation |

| Energy Consumption | Moderate due to cooling requirements | Low, passive operation |

| Typical Applications | Moisture control, heat recovery in cement plants | Air pollution control, dust removal in cement manufacturing |

Introduction to Condensers and Cyclone Separators

Condensers are heat exchangers designed to cool vapor into liquid by removing heat, commonly used in HVAC systems and industrial processes to reclaim condensate and improve efficiency. Cyclone separators utilize centrifugal force to separate particulate matter from air or gas streams, effectively removing dust and debris without filters. Your choice between the two depends on whether you need to condense vapor or separate solid particles from a gas flow.

What is a Condenser?

A condenser is a heat exchanger designed to cool and condense vapor into liquid by removing latent heat through a cooling medium, commonly used in HVAC systems, refrigeration, and industrial processes. Its function is critical for recovering condensate or enabling phase change for energy efficiency and system performance. Condensers vary in types, including shell-and-tube, air-cooled, and plate, each optimized for specific thermal management needs.

What is a Cyclone Separator?

A cyclone separator is a device that uses centrifugal force to separate particles from an air, gas, or liquid stream without the use of filters. It is commonly employed in industrial processes to remove dust and other particulates from emissions, enhancing air quality and protecting equipment. Compared to condensers, cyclone separators are specifically designed for solid-liquid or solid-gas separation through rotational motion rather than condensation of vapors.

How Do Condensers Work?

Condensers work by cooling vapor into a liquid through heat exchange, typically using a cooling medium such as air or water to absorb the heat from the vapor. The process involves the vapor losing thermal energy, causing molecules to slow down and transition from a gaseous state to a liquid state, which can then be collected. This phase change is crucial in systems like HVAC, refrigeration, and industrial processes to efficiently remove and recycle condensed fluids.

How Do Cyclone Separators Work?

Cyclone separators operate by utilizing centrifugal force to separate particles from air or liquid streams. As the fluid enters the cyclone chamber at high speed, the design creates a spiral motion that forces heavier particles outward toward the chamber walls, where they fall into a collection area. You can rely on this efficient separation method to remove dust, debris, and other contaminants without the need for filters.

Key Differences Between Condensers and Cyclone Separators

Condensers primarily function by cooling vapor to convert it into liquid, using heat exchange surfaces, whereas cyclone separators utilize centrifugal force to separate solid particles or liquid droplets from gas streams without phase change. Condensers are essential in processes requiring phase transformation, such as distillation and refrigeration, while cyclone separators are crucial for air pollution control, dust collection, and gas cleaning operations. The operational mechanism, phase interaction, and typical applications distinctly differentiate condensers from cyclone separators in industrial systems.

Applications of Condensers

Condensers are widely used in HVAC systems, refrigeration, and power plants to convert vapor into liquid, enhancing energy efficiency and system performance. In chemical processing industries, condensers facilitate the recovery of solvents and improve separation processes by condensing vapor streams. They are essential in distillation columns, where controlling temperature and phase change is crucial for product purity.

Applications of Cyclone Separators

Cyclone separators are widely used in industries for removing particulate matter from air, gas, or liquid streams, making them essential in pollution control and dust collection systems. Common applications include woodworking shops, cement plants, chemical processing, and power plants where they efficiently separate solid contaminants without the need for filters. Their design allows for handling high flow rates and abrasive materials, making them ideal for industrial dust extraction and gas purification.

Pros and Cons: Condenser vs Cyclone Separator

Condenser systems excel in efficiently removing moisture and improving air quality by cooling vapors to liquid form, but they require significant energy input and maintenance to prevent corrosion and fouling. Cyclone separators offer robust, low-maintenance separation of particulate matter from gases using centrifugal force, performing well in dusty environments without needing power, yet they are less effective at capturing fine particles and moisture. Your choice depends on whether you prioritize moisture removal and air cooling or durable dust and particle separation.

Choosing the Right Device for Your Process

Selecting the right device between a condenser and a cyclone separator depends on the specific requirements of your process, such as the type of substance to be separated and operational conditions. Condensers are ideal for vapor-to-liquid phase changes, effectively cooling and condensing gases, making them suitable for distillation and chemical reactions requiring heat recovery. Cyclone separators excel in removing solid particles from gas streams through centrifugal forces, offering high efficiency in dust collection and industrial air pollution control.

Condenser vs Cyclone Separator Infographic

libmatt.com

libmatt.com