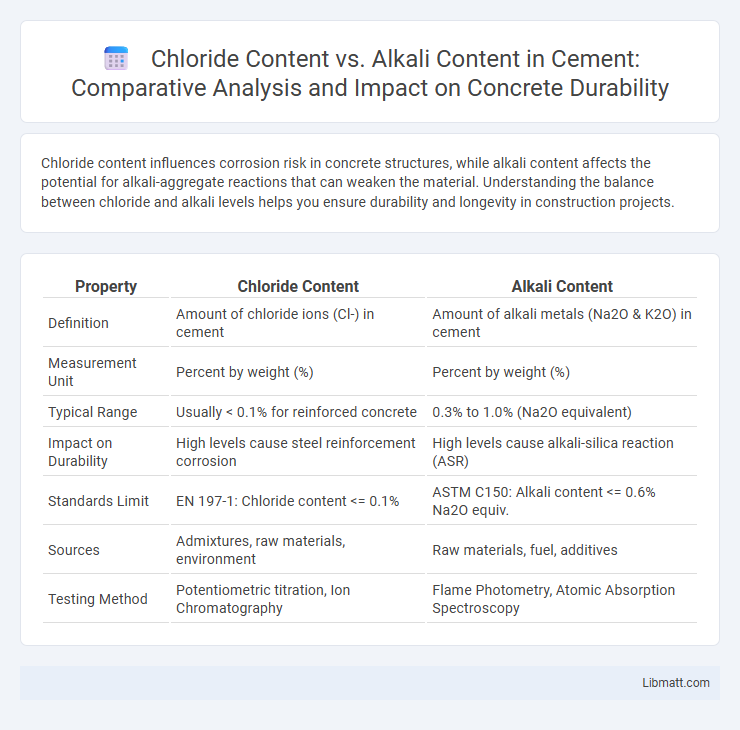

Chloride content influences corrosion risk in concrete structures, while alkali content affects the potential for alkali-aggregate reactions that can weaken the material. Understanding the balance between chloride and alkali levels helps you ensure durability and longevity in construction projects.

Table of Comparison

| Property | Chloride Content | Alkali Content |

|---|---|---|

| Definition | Amount of chloride ions (Cl-) in cement | Amount of alkali metals (Na2O & K2O) in cement |

| Measurement Unit | Percent by weight (%) | Percent by weight (%) |

| Typical Range | Usually < 0.1% for reinforced concrete | 0.3% to 1.0% (Na2O equivalent) |

| Impact on Durability | High levels cause steel reinforcement corrosion | High levels cause alkali-silica reaction (ASR) |

| Standards Limit | EN 197-1: Chloride content <= 0.1% | ASTM C150: Alkali content <= 0.6% Na2O equiv. |

| Sources | Admixtures, raw materials, environment | Raw materials, fuel, additives |

| Testing Method | Potentiometric titration, Ion Chromatography | Flame Photometry, Atomic Absorption Spectroscopy |

Introduction to Chloride and Alkali Content

Chloride content refers to the concentration of chloride ions (Cl-) within a substance, playing a crucial role in concrete durability by influencing corrosion of steel reinforcement. Alkali content pertains to the presence of alkali metals such as sodium (Na) and potassium (K), which affect the chemical stability and reactiveness in materials like cement. Monitoring chloride and alkali levels is essential for predicting material performance and preventing structural degradation in construction applications.

Importance of Chloride and Alkali in Materials

Chloride content influences the corrosion resistance and durability of concrete-based materials by accelerating steel reinforcement corrosion, while alkali content affects the chemical stability and reactivity within cementitious compounds, impacting strength and setting time. Managing chloride and alkali levels is essential to prevent structural degradation and ensure material longevity in construction applications. Understanding the balance between these components helps optimize your material performance and mitigate risks related to durability and safety.

Chemical Properties of Chloride vs Alkali

Chloride ions (Cl-) exhibit high solubility and strong ionic bonding, contributing to corrosion in metals, while alkali metals (such as sodium and potassium) form highly reactive hydroxides when combined with water, resulting in strong alkaline solutions. Chlorides primarily influence chemical stability and conductivity in aqueous environments, whereas alkali contents affect pH levels and catalytic activity in chemical processes. Understanding the distinct chemical behaviors of chloride and alkali elements is essential in materials science and environmental chemistry to control corrosion and alkalinity.

Sources of Chloride and Alkali Contamination

Chloride contamination primarily originates from de-icing salts, seawater exposure, and certain industrial processes involving chlorides, which can accelerate corrosion in concrete and steel. Alkali contamination is often introduced through cementitious materials, chemical admixtures, and environmental pollutants like alkali-rich dust and ash. Both chloride and alkali contents critically affect the durability and structural integrity of construction materials, necessitating rigorous testing and control measures.

Measuring Chloride Content in Materials

Measuring chloride content in materials is crucial for assessing corrosion risk, particularly in concrete and metals used in construction. Accurate chloride quantification involves methods such as potentiometric titration, ion-selective electrodes, and ion chromatography, each offering varying sensitivity and precision. Your understanding of chloride concentration helps in selecting appropriate corrosion-resistant materials and maintaining structural integrity over time.

Assessing Alkali Content: Methods and Standards

Assessing alkali content involves standardized methods such as flame photometry, atomic absorption spectroscopy (AAS), and inductively coupled plasma (ICP) analysis to precisely measure sodium and potassium levels in materials. Standards like ASTM C114 and ISO 22178 ensure consistent evaluation of alkali content in cement and concrete, aiding in predicting alkali-silica reaction potential. Accurate alkali quantification is critical for maintaining concrete durability and preventing structural damage caused by excessive alkali content.

Impact of Chloride Content on Material Durability

High chloride content in concrete significantly accelerates corrosion of steel reinforcement, compromising structural integrity and reducing material durability. Elevated chloride ions penetrate concrete pores, facilitating electrochemical reactions that lead to rust formation and subsequent cracking or spalling. Managing chloride levels below critical thresholds is essential to enhance longevity and maintain the strength of reinforced concrete structures.

Effects of Alkali Content on Structural Performance

Alkali content in concrete significantly influences its structural performance by affecting the alkali-silica reaction (ASR), which can cause cracking and reduction in strength. Elevated alkali levels promote expansive gel formation, leading to internal stress and compromised durability over time. You should carefully control alkali content to enhance long-term stability and prevent premature structural deterioration.

Managing Chloride and Alkali Levels in Construction

Effective management of chloride content and alkali content is critical in construction to prevent corrosion and alkali-silica reaction (ASR) in concrete structures. High chloride levels accelerate steel reinforcement corrosion, compromising structural integrity, while excessive alkali content can trigger ASR, causing concrete cracking and durability loss. Controlling these factors through material selection, admixtures, and proper mix design ensures Your construction projects achieve long-term strength and durability.

Conclusion: Optimizing Chloride and Alkali Balance

Balancing chloride content and alkali content is crucial for maintaining the durability and performance of concrete structures, as excessive chlorides accelerate corrosion while alkalis influence concrete alkalinity and resistance. Optimizing this balance involves careful monitoring and control of raw material compositions to prevent structural damage and prolong service life. You can enhance material stability and structural integrity by ensuring chloride levels remain low while maintaining adequate alkali concentrations.

Chloride Content vs Alkali Content Infographic

libmatt.com

libmatt.com