Baghouse dust collectors use fabric filter bags to capture fine dust particles, providing high-efficiency filtration for industries requiring precise air quality control. Your choice between a baghouse and an electrostatic precipitator (ESP) depends on factors such as particle size, moisture content, and maintenance needs, as ESPs use electrical charges to remove particles but may be less effective with sticky or wet dust.

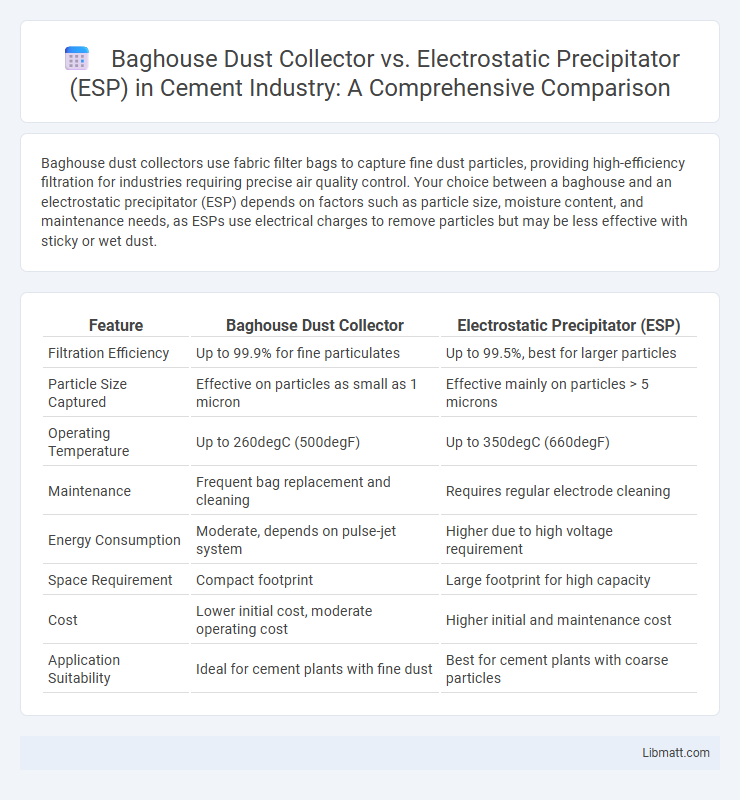

Table of Comparison

| Feature | Baghouse Dust Collector | Electrostatic Precipitator (ESP) |

|---|---|---|

| Filtration Efficiency | Up to 99.9% for fine particulates | Up to 99.5%, best for larger particles |

| Particle Size Captured | Effective on particles as small as 1 micron | Effective mainly on particles > 5 microns |

| Operating Temperature | Up to 260degC (500degF) | Up to 350degC (660degF) |

| Maintenance | Frequent bag replacement and cleaning | Requires regular electrode cleaning |

| Energy Consumption | Moderate, depends on pulse-jet system | Higher due to high voltage requirement |

| Space Requirement | Compact footprint | Large footprint for high capacity |

| Cost | Lower initial cost, moderate operating cost | Higher initial and maintenance cost |

| Application Suitability | Ideal for cement plants with fine dust | Best for cement plants with coarse particles |

Introduction to Industrial Air Filtration

Baghouse dust collectors use fabric filters to capture particulate matter from industrial emissions, providing high-efficiency filtration for fine dust particles. Electrostatic precipitators (ESPs) employ electrical charges to remove particles by attracting them to collection plates, excelling in handling large gas volumes with lower pressure drops. Your choice between these systems depends on factors such as particle size, gas temperature, and maintenance requirements in industrial air filtration.

Overview of Baghouse Dust Collectors

Baghouse dust collectors use fabric filter bags to capture particulate matter from industrial exhaust streams, offering high filtration efficiency for fine dust particles. These systems operate by drawing contaminated air through the filter bags, where dust accumulates and clean air is released. Baghouse collectors are widely preferred for their ability to handle large volumes of dust-laden air with low pressure drop and reliable particulate removal.

Understanding Electrostatic Precipitators (ESP)

Electrostatic Precipitators (ESPs) use electrical charges to remove fine particulate matter from industrial exhaust gases by attracting dust particles to oppositely charged collection plates. This technology offers high-efficiency filtration for fine aerosols and smoke, making ESPs ideal for industries requiring stringent air quality control. Your choice between an ESP and a Baghouse Dust Collector depends on factors such as particle size, gas composition, and maintenance requirements.

Key Working Principles: Baghouse vs ESP

Baghouse dust collectors operate by filtering particle-laden air through fabric filter bags that trap dust on their surface, allowing clean air to pass through. Electrostatic precipitators (ESP) utilize electrical charges to ionize dust particles, which are then attracted to and collected on oppositely charged plates. Baghouse systems rely on mechanical filtration, while ESPs depend on electrical forces to remove particulate matter from industrial exhaust streams.

Filtration Efficiency Comparison

Baghouse dust collectors achieve filtration efficiencies of up to 99.9%, effectively capturing fine particulate matter through fabric filter media. Electrostatic precipitators (ESPs) typically offer slightly lower efficiencies, ranging from 85% to 99%, relying on electrical charges to remove particles from the airflow. Your choice between these systems should consider the particle size distribution and specific filtration requirements to optimize air quality control.

Particle Size and Type Suitability

Baghouse dust collectors excel at capturing fine and dry particulate matter, including particles as small as 0.5 microns, making them ideal for filters sensitive to dust load and composition. Electrostatic precipitators (ESPs) are more effective for larger, dry or slightly moist particles typically above 1 micron, especially in high-temperature gas streams. Your choice depends on the specific particle size distribution and the nature of the dust, with baghouses preferred for fine, fibrous dust and ESPs suited for coarser, conductive particles.

Maintenance and Operating Costs

Baghouse dust collectors generally incur higher maintenance costs due to frequent bag replacements and routine inspections, while electrostatic precipitators (ESPs) require less frequent maintenance but involve complex electrical systems that demand specialized expertise. Operating costs for baghouses include energy consumption for air blowers and periodic bag replacement, whereas ESPs consume significant power to maintain high voltage but benefit from lower consumable expenses. Your choice depends on balancing the routine maintenance frequency and the specific power consumption profile associated with each technology.

Energy Consumption Differences

Baghouse dust collectors typically consume more energy due to the power needed to operate their pulse-jet cleaning systems and fans. Electrostatic precipitators (ESPs) generally use less energy as they rely on electrical charges to capture particles, making them more efficient for large volumes of flue gas. Your choice between the two should consider operational costs influenced by these energy consumption differences.

Application Areas and Industry Suitability

Baghouse dust collectors excel in applications involving fine particulate filtration in industries such as cement, pharmaceuticals, and food processing, offering high efficiency in capturing dust and allergens. Electrostatic precipitators (ESPs) are more suited for large industrial operations like power plants and steel mills, where they effectively remove larger particles and manage high volume flue gases. Your choice between these systems depends on industry-specific requirements like particle size, gas volume, and regulatory standards.

Selecting the Right System: Baghouse or ESP

Selecting the right particulate control system depends on factors such as particle size distribution, gas volume, temperature, and dust characteristics. Baghouse dust collectors excel at capturing fine, dry particulates with high collection efficiency exceeding 99.9%, making them ideal for applications involving smaller particles and varying gas stream conditions. Electrostatic precipitators (ESPs) are more effective for handling large gas volumes and particles with high resistivity, offering low operational costs and reliability in industries like power generation and cement manufacturing.

Baghouse Dust Collector vs ESP Infographic

libmatt.com

libmatt.com