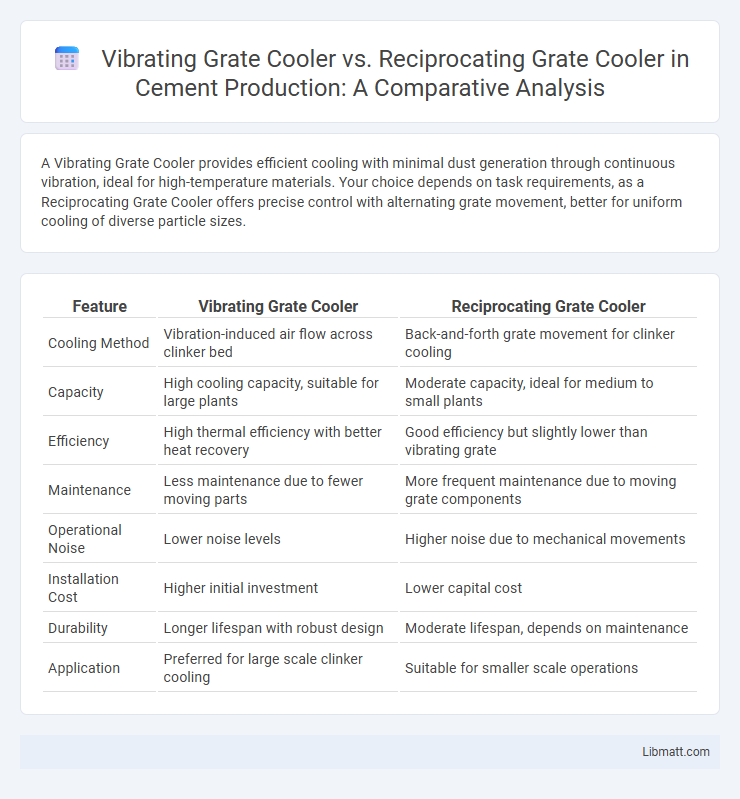

A Vibrating Grate Cooler provides efficient cooling with minimal dust generation through continuous vibration, ideal for high-temperature materials. Your choice depends on task requirements, as a Reciprocating Grate Cooler offers precise control with alternating grate movement, better for uniform cooling of diverse particle sizes.

Table of Comparison

| Feature | Vibrating Grate Cooler | Reciprocating Grate Cooler |

|---|---|---|

| Cooling Method | Vibration-induced air flow across clinker bed | Back-and-forth grate movement for clinker cooling |

| Capacity | High cooling capacity, suitable for large plants | Moderate capacity, ideal for medium to small plants |

| Efficiency | High thermal efficiency with better heat recovery | Good efficiency but slightly lower than vibrating grate |

| Maintenance | Less maintenance due to fewer moving parts | More frequent maintenance due to moving grate components |

| Operational Noise | Lower noise levels | Higher noise due to mechanical movements |

| Installation Cost | Higher initial investment | Lower capital cost |

| Durability | Longer lifespan with robust design | Moderate lifespan, depends on maintenance |

| Application | Preferred for large scale clinker cooling | Suitable for smaller scale operations |

Introduction to Grate Coolers in Clinker Production

Grate coolers play a critical role in clinker production by efficiently cooling hot clinker particles while recovering heat for energy conservation. Vibrating grate coolers use a vibrating motion to move clinker through cooling zones, providing uniform cooling and enhanced heat recovery rates compared to reciprocating grate coolers, which rely on a back-and-forth movement of grate plates. Understanding the operational differences between these coolers can help optimize your clinker production process by improving thermal efficiency and clinker quality.

Vibrating Grate Cooler: Working Principle

The Vibrating Grate Cooler operates by using vibration to efficiently cool hot materials like clinker or minerals as they move across the grate surface, promoting uniform heat transfer and rapid cooling. Its working principle involves mechanical vibrations that facilitate material agitation, preventing clinker accumulation while enabling continuous airflow through the bed for optimized thermal exchange. This design enhances cooling efficiency, reduces energy consumption, and improves the overall throughput compared to stationary or reciprocating grate coolers.

Reciprocating Grate Cooler: Mechanism and Operation

The Reciprocating Grate Cooler operates by moving hot clinker through a series of reciprocating grate plates, allowing air to pass upward and cool the material efficiently. Its mechanism involves a back-and-forth motion that advances the clinker incrementally while maximizing heat exchange with the cooling air. This design enhances thermal recovery and clinker quality, making it ideal for cement plant operations requiring consistent and effective clinker cooling.

Key Design Differences Between Vibrating and Reciprocating Grate Coolers

Vibrating grate coolers utilize a vibration mechanism to move the material smoothly over the cooling surface, enabling high heat transfer efficiency and uniform cooling, while reciprocating grate coolers rely on a back-and-forth movement of the grate bars to transport and cool the material, providing effective handling of larger, coarser particles. The vibrating grate design typically features fewer moving parts and lower maintenance requirements compared to the reciprocating grate's more mechanically complex system, which involves multiple linkages and drive components. Cooling efficiency in vibrating grates is often enhanced by the rapid agitation and mixing of materials, whereas reciprocating grates offer better control over material flow rate and cooling time by adjusting stroke length and frequency.

Efficiency and Heat Recovery Comparison

Vibrating Grate Coolers offer higher thermal efficiency by providing uniform cooling and improved heat recovery through constant material movement that optimizes air flow and heat transfer. Reciprocating Grate Coolers, while effective, generally exhibit lower heat recovery rates due to intermittent material movement, causing uneven cooling and heat loss. Your choice between these systems should consider the specific heat recovery needs and operational efficiency demands of your industrial process.

Maintenance Requirements and Durability

Vibrating grate coolers require regular inspection and frequent lubrication due to their complex moving parts, which can increase maintenance efforts compared to reciprocating grate coolers. Reciprocating grate coolers have a simpler mechanical design with fewer moving components, resulting in lower maintenance demands and enhanced durability under continuous operation. Steel construction and modular grate segments in both types contribute to longevity, but vibrating grate coolers often experience faster wear due to higher vibration-induced stresses.

Energy Consumption and Cost Analysis

Vibrating grate coolers typically consume less energy due to their continuous airflow system, which improves heat transfer efficiency compared to reciprocating grate coolers that operate with intermittent motion and higher mechanical energy use. The initial cost of vibrating grate coolers tends to be higher, but lower operational expenses and reduced maintenance requirements can lead to better long-term cost-effectiveness. Your choice should consider the trade-off between upfront investment and ongoing energy costs to optimize overall plant performance.

Impact on Clinker Quality and Output

Vibrating Grate Coolers offer superior cooling efficiency and uniform clinker temperature distribution, directly enhancing clinker quality by reducing thermal stress and preventing material degradation. Reciprocating Grate Coolers typically provide less consistent cooling, potentially causing uneven clinker hardness and impacting output stability. Optimizing your cooler choice improves both clinker quality and overall production output, ensuring more reliable performance in cement manufacturing.

Environmental Considerations and Emissions

Vibrating grate coolers reduce dust emissions and improve air quality through enhanced airflow control, making them more environmentally friendly compared to reciprocating grate coolers. Reciprocating grate coolers often generate higher particulate matter due to less efficient fuel cooling and combustion air distribution. Implementing advanced dust collection systems in vibrating grate coolers significantly lowers greenhouse gas emissions and complies better with environmental regulations.

Choosing the Right Grate Cooler: Factors to Consider

Selecting the appropriate grate cooler depends on factors such as heat recovery efficiency, material particle size, and maintenance requirements. Vibrating grate coolers offer superior temperature uniformity and are ideal for fine particles, enhancing thermal exchange and prolonging equipment life. Reciprocating grate coolers excel in handling larger, abrasive materials but may require more frequent maintenance due to mechanical complexity.

Vibrating Grate Cooler vs Reciprocating Grate Cooler Infographic

libmatt.com

libmatt.com