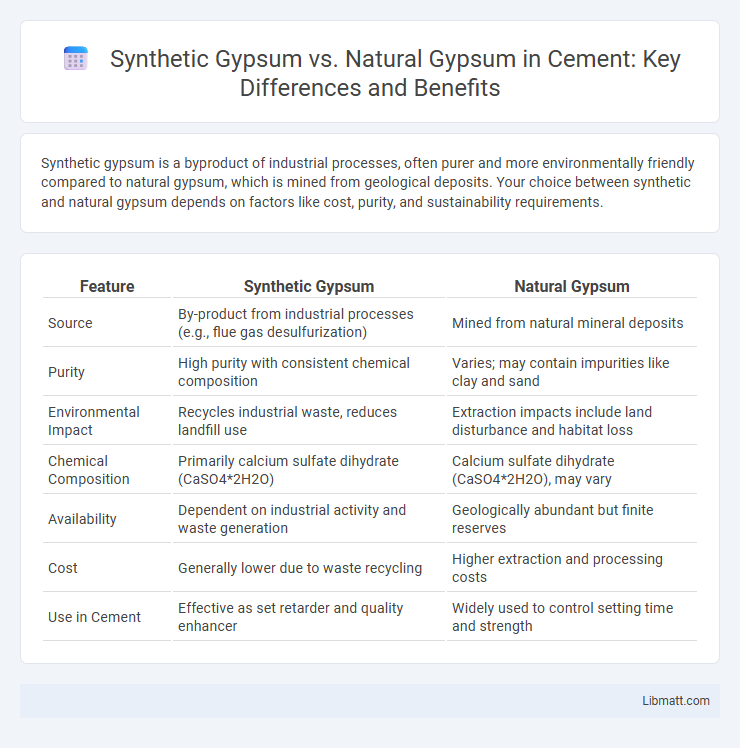

Synthetic gypsum is a byproduct of industrial processes, often purer and more environmentally friendly compared to natural gypsum, which is mined from geological deposits. Your choice between synthetic and natural gypsum depends on factors like cost, purity, and sustainability requirements.

Table of Comparison

| Feature | Synthetic Gypsum | Natural Gypsum |

|---|---|---|

| Source | By-product from industrial processes (e.g., flue gas desulfurization) | Mined from natural mineral deposits |

| Purity | High purity with consistent chemical composition | Varies; may contain impurities like clay and sand |

| Environmental Impact | Recycles industrial waste, reduces landfill use | Extraction impacts include land disturbance and habitat loss |

| Chemical Composition | Primarily calcium sulfate dihydrate (CaSO4*2H2O) | Calcium sulfate dihydrate (CaSO4*2H2O), may vary |

| Availability | Dependent on industrial activity and waste generation | Geologically abundant but finite reserves |

| Cost | Generally lower due to waste recycling | Higher extraction and processing costs |

| Use in Cement | Effective as set retarder and quality enhancer | Widely used to control setting time and strength |

Introduction to Gypsum: Synthetic vs Natural

Synthetic gypsum is a byproduct of industrial processes like flue gas desulfurization, while natural gypsum is a mineral extracted from geological deposits. Both types share calcium sulfate dihydrate composition but differ in purity, environmental impact, and availability. Your choice between synthetic and natural gypsum influences sustainability, cost, and material performance in construction or agriculture.

Composition and Formation of Synthetic Gypsum

Synthetic gypsum primarily consists of calcium sulfate dihydrate, formed as a byproduct from industrial processes such as flue gas desulfurization in power plants. Unlike natural gypsum, which is mined from sedimentary rock deposits formed over millions of years by the evaporation of ancient seas, synthetic gypsum results from controlled chemical reactions capturing sulfur dioxide emissions. The purity and fine crystalline structure of synthetic gypsum often make it advantageous for construction applications compared to variability in natural gypsum deposits.

Geological Origins of Natural Gypsum

Natural gypsum forms through the evaporation of seawater in sedimentary basins, resulting in crystalline deposits over millions of years. This geological origin gives natural gypsum its characteristic purity and mineral composition, influenced by the surrounding environment during formation. Understanding these properties can help you choose the right gypsum type for construction or agricultural applications.

Environmental Impact: Synthetic Gypsum Production

Synthetic gypsum production significantly reduces environmental impact by utilizing industrial by-products such as flue gas desulfurization (FGD) gypsum, which would otherwise be disposed of in landfills. This recycling process lowers greenhouse gas emissions and minimizes the mining disturbances associated with natural gypsum extraction. Furthermore, synthetic gypsum helps conserve natural gypsum deposits, promoting sustainable resource management and reducing habitat destruction.

Environmental Benefits and Drawbacks of Natural Gypsum

Natural gypsum, formed through geological processes over millions of years, is a finite resource whose extraction impacts landscapes and ecosystems, often leading to habitat disruption and soil erosion. While it requires less processing than synthetic gypsum, its mining generates dust, consumes energy, and can cause water pollution, contributing to a notable environmental footprint. Understanding these drawbacks highlights the importance of balancing gypsum sourcing in construction projects to optimize environmental benefits for Your sustainable development goals.

Cost Comparison: Synthetic vs Natural Gypsum

Synthetic gypsum typically costs less than natural gypsum due to lower extraction and transportation expenses, as it is a byproduct of industrial processes such as flue gas desulfurization. Natural gypsum involves mining operations that add to its overall price, including labor, equipment, and environmental management costs. Your project budget can benefit from choosing synthetic gypsum when aiming for cost efficiency without compromising material quality.

Quality and Purity Differences

Synthetic gypsum generally exhibits higher purity levels with fewer impurities such as heavy metals and organic contaminants compared to natural gypsum, which often contains variable mineral compositions depending on its geological source. The controlled manufacturing process of synthetic gypsum ensures consistent quality, making it ideal for applications requiring precise chemical properties, such as in cement production and drywall manufacturing. Your choice between synthetic and natural gypsum impacts the final product's durability and performance due to these significant quality and purity differences.

Industrial Applications of Both Gypsum Types

Synthetic gypsum, primarily generated as a byproduct from flue gas desulfurization in power plants, is extensively used in the construction industry for manufacturing drywall, plaster, and cement due to its purity and consistent quality. Natural gypsum, mined from sedimentary deposits, finds broad applications in soil conditioning, agriculture as a calcium and sulfur fertilizer, and in the production of cement and plasterboard, leveraging its natural mineral properties. Both types are integral to industrial processes, with synthetic gypsum providing an environmentally sustainable alternative while natural gypsum remains a key raw material in traditional applications.

Sustainability and Future Trends

Synthetic gypsum, a byproduct of industrial processes such as flue gas desulfurization, offers a more sustainable alternative to natural gypsum by reducing waste and lowering the environmental impact of mining activities. Its utilization supports circular economy principles by recycling industrial emissions into valuable construction materials, promoting resource efficiency. Future trends indicate increased adoption of synthetic gypsum in the cement and wallboard industries driven by stricter environmental regulations and advancements in processing technology.

Conclusion: Choosing the Right Gypsum

Synthetic gypsum offers a more sustainable alternative with its lower environmental impact and consistent chemical composition compared to natural gypsum, which is mined and subject to geological variability. Your decision should consider factors like availability, cost-effectiveness, environmental goals, and project requirements, as synthetic gypsum is often ideal for eco-friendly construction, while natural gypsum remains preferred for traditional applications. Balancing these aspects ensures you select the right gypsum type to optimize performance and sustainability in your project.

Synthetic Gypsum vs Natural Gypsum Infographic

libmatt.com

libmatt.com