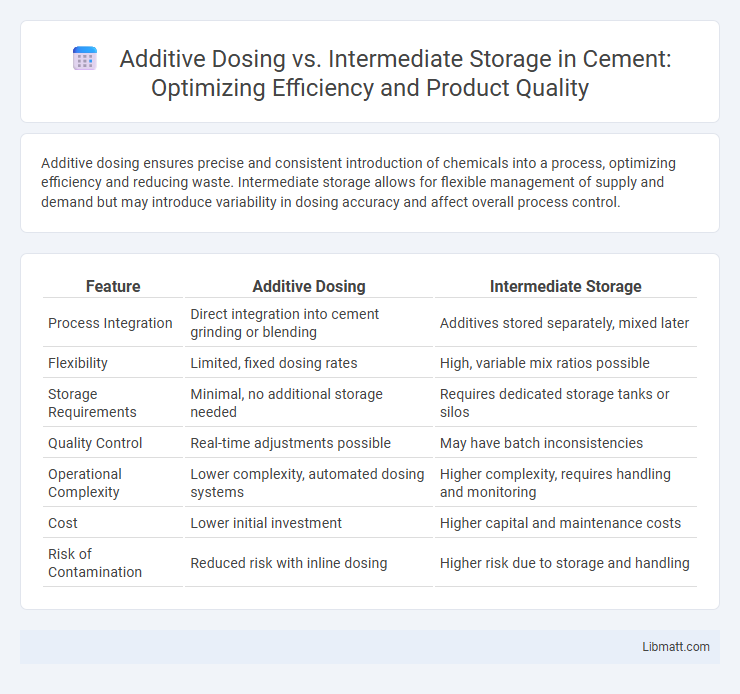

Additive dosing ensures precise and consistent introduction of chemicals into a process, optimizing efficiency and reducing waste. Intermediate storage allows for flexible management of supply and demand but may introduce variability in dosing accuracy and affect overall process control.

Table of Comparison

| Feature | Additive Dosing | Intermediate Storage |

|---|---|---|

| Process Integration | Direct integration into cement grinding or blending | Additives stored separately, mixed later |

| Flexibility | Limited, fixed dosing rates | High, variable mix ratios possible |

| Storage Requirements | Minimal, no additional storage needed | Requires dedicated storage tanks or silos |

| Quality Control | Real-time adjustments possible | May have batch inconsistencies |

| Operational Complexity | Lower complexity, automated dosing systems | Higher complexity, requires handling and monitoring |

| Cost | Lower initial investment | Higher capital and maintenance costs |

| Risk of Contamination | Reduced risk with inline dosing | Higher risk due to storage and handling |

Understanding Additive Dosing and Intermediate Storage

Additive dosing precisely controls the introduction of specific substances into a process, ensuring optimal concentration and reaction efficiency. Intermediate storage temporarily holds additives or materials, maintaining process continuity and accommodating fluctuations in supply or demand. These methods collectively enhance production stability and product quality by balancing dosing accuracy and storage flexibility.

Key Differences Between Additive Dosing and Intermediate Storage

Additive dosing involves the precise, controlled injection of chemicals directly into a process stream, ensuring accurate concentration and real-time adjustment of formulations. Intermediate storage refers to holding bulk chemicals in tanks or containers for future use, which allows for inventory management but lacks immediate process integration or control. Your choice depends on process requirements: additive dosing offers dynamic precision, while intermediate storage prioritizes capacity and logistical flexibility.

Pros and Cons of Additive Dosing

Additive dosing offers precise control over chemical concentrations, enhancing efficiency in processes such as water treatment and manufacturing. However, it requires careful calibration and continuous monitoring to prevent under- or overdosing, which can lead to operational inefficiencies or safety hazards. Compared to intermediate storage, additive dosing minimizes storage space and reduces the risk of contamination or degradation of chemicals over time.

Advantages and Disadvantages of Intermediate Storage

Intermediate storage offers the advantage of buffering production processes by storing additives or materials temporarily, ensuring continuous operation during supply fluctuations. However, it requires additional space, investment in storage facilities, and careful management to prevent contamination or degradation of stored materials. Your production efficiency benefits from intermediate storage when demand variability is high, but operational complexity and costs may increase compared to additive dosing systems.

Application Scenarios: When to Use Additive Dosing

Additive dosing is ideal for precise chemical or nutrient delivery in applications like water treatment, agriculture, and food processing where exact concentrations are critical. It suits scenarios requiring continuous injection of additives into pipelines or tanks to maintain consistent quality or reaction conditions. In contrast, intermediate storage fits bulk material handling or batch processes where additives are stored before final blending or usage.

Application Scenarios: When to Choose Intermediate Storage

Intermediate storage is ideal for applications with fluctuating production rates or batch processing, enabling flexible decoupling between dosing and downstream processes. It suits scenarios requiring temporary buffering of additives to maintain consistent supply despite variable demand or supply interruptions. Selecting intermediate storage enhances process stability and efficiency in complex, large-scale chemical manufacturing or food production lines.

Impact on Product Quality and Safety

Additive dosing ensures precise control over ingredient concentrations, directly enhancing product quality by maintaining consistency and preventing contamination associated with delayed mixing. In contrast, intermediate storage can introduce risks of microbial growth, chemical degradation, and cross-contamination, negatively affecting both safety and product integrity. Implementing real-time dosing systems reduces variability and improves traceability, which are critical for complying with stringent safety standards in food and pharmaceutical manufacturing.

Cost Implications of Additive Dosing vs Intermediate Storage

Additive dosing often results in lower operational costs by minimizing the need for large storage facilities, reducing capital expenditure and inventory holding expenses. Intermediate storage requires significant investment in space, maintenance, and handling, increasing total cost of ownership and risk of product degradation. Your cost management strategy should weigh these factors, ensuring efficient resource allocation and budget optimization.

Regulatory Considerations and Compliance

Additive dosing systems must comply with stringent regulatory standards such as FDA 21 CFR Part 11 for electronic records and GMP guidelines to ensure accurate and traceable chemical additions. Intermediate storage of additives requires adherence to OSHA and EPA regulations, including proper labeling, containment, and monitoring to prevent contamination and environmental hazards. Both methods demand comprehensive documentation and validation processes to maintain compliance with industry-specific safety and quality requirements.

Future Trends in Additive Dosing and Intermediate Storage

Future trends in additive dosing emphasize increased automation and real-time monitoring through IoT integration, enhancing precision in chemical blending and reducing human error. Intermediate storage innovations focus on modular, scalable systems with advanced materials that ensure stability and safety while minimizing contamination risks. Both areas are moving towards environmentally sustainable solutions, incorporating energy-efficient technologies and smart sensors for optimized resource management.

Additive dosing vs Intermediate storage Infographic

libmatt.com

libmatt.com