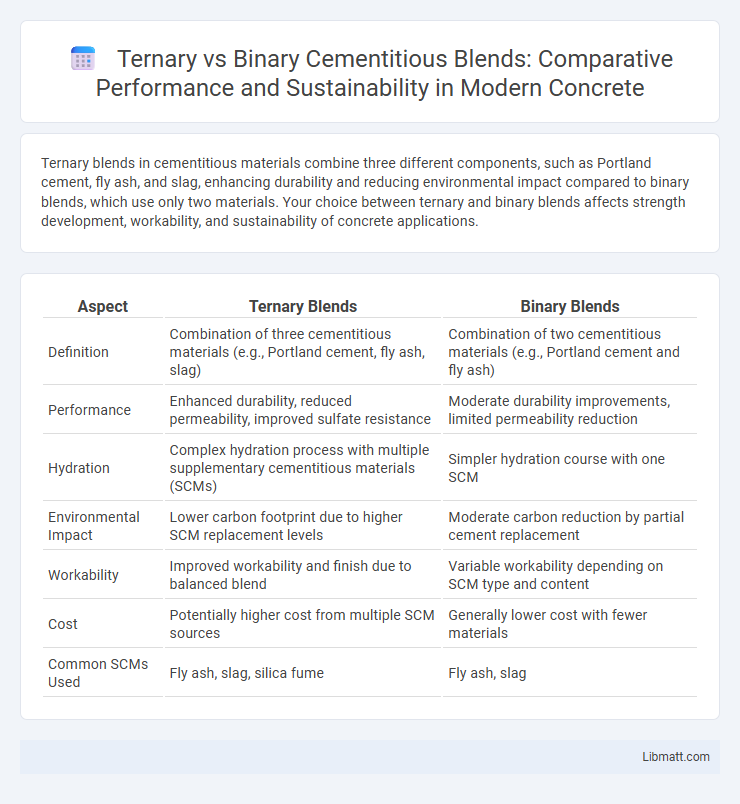

Ternary blends in cementitious materials combine three different components, such as Portland cement, fly ash, and slag, enhancing durability and reducing environmental impact compared to binary blends, which use only two materials. Your choice between ternary and binary blends affects strength development, workability, and sustainability of concrete applications.

Table of Comparison

| Aspect | Ternary Blends | Binary Blends |

|---|---|---|

| Definition | Combination of three cementitious materials (e.g., Portland cement, fly ash, slag) | Combination of two cementitious materials (e.g., Portland cement and fly ash) |

| Performance | Enhanced durability, reduced permeability, improved sulfate resistance | Moderate durability improvements, limited permeability reduction |

| Hydration | Complex hydration process with multiple supplementary cementitious materials (SCMs) | Simpler hydration course with one SCM |

| Environmental Impact | Lower carbon footprint due to higher SCM replacement levels | Moderate carbon reduction by partial cement replacement |

| Workability | Improved workability and finish due to balanced blend | Variable workability depending on SCM type and content |

| Cost | Potentially higher cost from multiple SCM sources | Generally lower cost with fewer materials |

| Common SCMs Used | Fly ash, slag, silica fume | Fly ash, slag |

Introduction to Cementitious Blends

Cementitious blends are essential in enhancing concrete performance by combining different materials to optimize strength, durability, and sustainability. Binary blends consist of two cementitious components, typically Portland cement and one supplementary material like fly ash or slag, improving workability and reducing carbon footprint. Ternary blends incorporate three components, often Portland cement with two supplementary materials, offering superior synergistic effects such as improved resistance to chemical attacks and reduced permeability.

Defining Binary Blends in Cement

Binary blends in cement consist of two components: Portland cement combined with a single supplementary cementitious material (SCM) such as fly ash, slag, or silica fume, to enhance specific properties of concrete. These blends improve workability, durability, and reduce the environmental footprint by partially replacing clinker content. The proportion and type of SCM in binary blends significantly influence strength development, setting time, and resistance to chemical attacks.

What Are Ternary Blends?

Ternary blends in cementitious materials consist of three distinct components, typically Portland cement combined with two supplementary cementitious materials (SCMs) such as fly ash, slag, or silica fume, enhancing durability and reducing environmental impact. These blends improve concrete performance by optimizing particle packing, refining pore structure, and increasing resistance to chemical attack compared to binary blends, which use only one SCM alongside cement. Understanding ternary blends allows you to tailor concrete mixtures for superior strength, sustainability, and long-term durability in construction projects.

Common Materials Used in Binary and Ternary Blends

Binary blends typically combine Portland cement with one supplementary cementitious material such as fly ash, slag, or silica fume, enhancing durability and reducing environmental impact. Ternary blends incorporate two supplementary materials alongside Portland cement, commonly combining fly ash and slag or slag and silica fume, which improve mechanical properties and long-term strength. Your choice between binary and ternary blends depends on the desired performance characteristics and sustainability goals in concrete applications.

Comparative Strength Development

Ternary blends incorporating three cementitious materials, such as fly ash, slag, and silica fume, exhibit enhanced long-term strength development compared to binary blends that use only two materials. The synergistic effect of multiple pozzolanic and latent hydraulic reactions in ternary blends results in denser microstructures and improved compressive strength at 28 and 90 days. Binary blends typically provide faster early strength gain but often lack the durability and peak strength levels achieved by ternary blends over extended curing periods.

Durability Aspects: Binary vs Ternary Blends

Ternary blends often enhance durability in cementitious materials by combining supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume, leading to reduced permeability and improved resistance to chemical attack compared to binary blends. Binary blends typically incorporate only one SCM, providing moderate durability improvements but less synergistic effect on microstructure refinement and reduced alkali-silica reactivity. The optimized pozzolanic reactions in ternary blends contribute to improved long-term strength and superior resistance to sulfate attack, chloride ingress, and carbonation.

Sustainability and Environmental Impact

Ternary blends in cementitious materials typically combine three components such as Portland cement, fly ash, and slag, reducing the overall clinker content and thereby significantly lowering CO2 emissions compared to binary blends, which mix only two components. The increased use of supplementary cementitious materials (SCMs) in ternary blends enhances durability and reduces the carbon footprint of concrete production, contributing to more sustainable construction practices. Life cycle assessments show ternary blends offer improved environmental performance by conserving natural resources and minimizing energy consumption during cement manufacturing.

Workability and Setting Times

Ternary blends, combining three cementitious materials such as Portland cement, fly ash, and slag, often enhance workability by improving particle packing and reducing water demand compared to binary blends. These blends tend to exhibit extended setting times due to the slower pozzolanic reactions of supplementary cementitious materials, which can be advantageous in hot weather concreting. Binary blends, consisting of two components like cement and fly ash, generally offer moderate workability and setting times, balancing early strength development with improved durability.

Cost Implications of Binary and Ternary Blends

Binary blends, typically consisting of Portland cement and one supplementary cementitious material (SCM) like fly ash or slag, often reduce initial material costs by lowering the cement content and utilizing industrial by-products. Ternary blends, incorporating two SCMs along with Portland cement, can further optimize cost efficiency by combining complementary properties that enhance durability and reduce maintenance expenses over the structure's lifespan. The complexity of mix design in ternary blends may increase upfront costs slightly but generally results in overall economic benefits due to improved performance and longevity compared to binary blends.

Applications and Best Practices in Construction

Ternary blends, combining Portland cement with two supplementary cementitious materials (SCMs) such as fly ash, slag, or silica fume, enhance durability and sustainability in large-scale infrastructure projects by reducing permeability and improving resistance to chemical attack. Binary blends, typically consisting of Portland cement and one SCM, provide cost-effective solutions for residential and commercial buildings where moderate performance improvements and lower carbon footprint are required. Best practices in construction recommend ternary blends for high-performance concrete applications like bridges and marine structures, while binary blends suit general-purpose concrete with optimized workability and strength development.

Ternary Blends vs Binary Blends (Cementitious Materials) Infographic

libmatt.com

libmatt.com