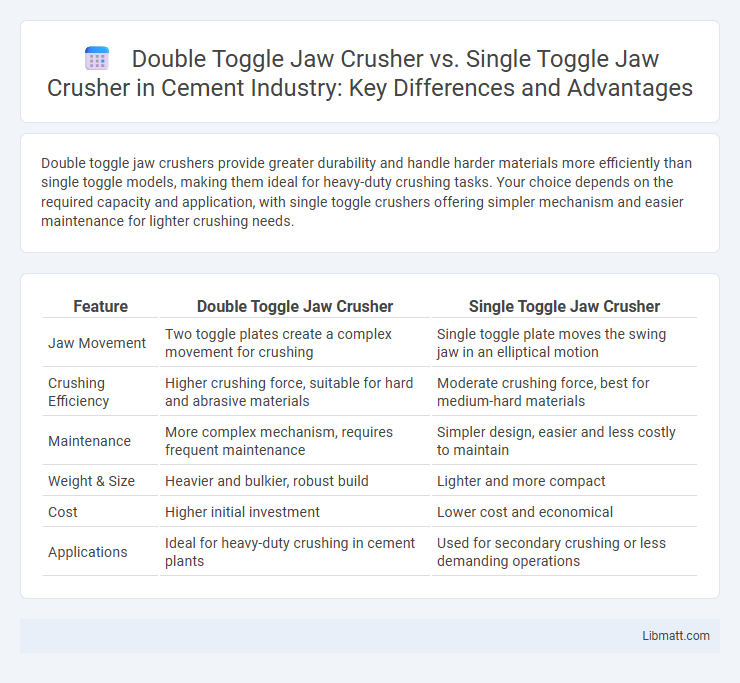

Double toggle jaw crushers provide greater durability and handle harder materials more efficiently than single toggle models, making them ideal for heavy-duty crushing tasks. Your choice depends on the required capacity and application, with single toggle crushers offering simpler mechanism and easier maintenance for lighter crushing needs.

Table of Comparison

| Feature | Double Toggle Jaw Crusher | Single Toggle Jaw Crusher |

|---|---|---|

| Jaw Movement | Two toggle plates create a complex movement for crushing | Single toggle plate moves the swing jaw in an elliptical motion |

| Crushing Efficiency | Higher crushing force, suitable for hard and abrasive materials | Moderate crushing force, best for medium-hard materials |

| Maintenance | More complex mechanism, requires frequent maintenance | Simpler design, easier and less costly to maintain |

| Weight & Size | Heavier and bulkier, robust build | Lighter and more compact |

| Cost | Higher initial investment | Lower cost and economical |

| Applications | Ideal for heavy-duty crushing in cement plants | Used for secondary crushing or less demanding operations |

Introduction to Jaw Crushers

Jaw crushers are essential machines in mining and construction for crushing rocks and ores. They come in two main types: double toggle and single toggle jaw crushers, distinguished by their crushing mechanisms and shaft movements. Double toggle jaw crushers feature two toggle plates and shafts for increased crushing force, while single toggle jaw crushers utilize a single toggle shaft for lighter, more efficient crushing.

Overview of Single Toggle Jaw Crusher

Single toggle jaw crushers feature a shaft located at the top of the crusher with a swing jaw that moves in an arc-like motion to crush material against a stationary plate. This design offers a simpler mechanism, reduced weight, and lower manufacturing costs compared to double toggle crushers, making it suitable for medium to soft materials. Single toggle crushers are widely used in mining and aggregate industries for their efficient crushing capacity and easier maintenance.

Overview of Double Toggle Jaw Crusher

The Double Toggle Jaw Crusher features two toggles and a more complex design, providing greater force and efficiency in crushing hard, abrasive materials. Its two shafts and two toggle plates ensure a more uniform distribution of stress, resulting in enhanced durability and reduced wear. You can expect the Double Toggle Jaw Crusher to deliver higher throughput and consistent particle size, making it ideal for heavy-duty industrial applications.

Key Design Differences

Double toggle jaw crushers feature two toggles and a more complex pivoting mechanism, resulting in increased durability and greater crushing force compared to single toggle jaw crushers, which use a simpler, single toggle mechanism with one pivot point. The double toggle design provides a more powerful crushing action and is suitable for heavy-duty, abrasive materials, while single toggle crushers are lighter, have fewer moving parts, and are easier to maintain, making them ideal for low to medium hardness materials. Your choice depends on the specific crushing needs, including material hardness, operating conditions, and maintenance preferences.

Working Principle Comparison

Double toggle jaw crushers operate with two shafts and two toggles, providing a more complex motion that results in a powerful crushing action suitable for hard, abrasive materials. Single toggle jaw crushers use one shaft and a simpler motion, which offers faster crushing but less force, making them ideal for softer or less abrasive materials. Your choice between the two depends on the desired crushing efficiency, material hardness, and maintenance preferences.

Performance and Efficiency

Double toggle jaw crushers exhibit higher crushing force and greater stability, resulting in enhanced performance when handling tough and abrasive materials. Single toggle jaw crushers offer improved efficiency with faster crushing cycles and lower energy consumption, making them ideal for applications requiring high throughput. Choosing between the two impacts your operational productivity based on material hardness and desired output.

Maintenance Requirements

Double Toggle Jaw Crushers demand more maintenance due to their complex mechanism with two toggles and additional moving parts, increasing wear and lubrication needs. Single Toggle Jaw Crushers have simpler designs, resulting in less frequent maintenance and easier access to components, saving your time and operational costs. Choosing a crusher depends on balancing maintenance frequency with production capacity and application requirements.

Application Suitability

Double toggle jaw crushers excel in heavy-duty applications requiring high crushing force and durability, making them ideal for mining and quarrying projects involving hard, abrasive materials. Single toggle jaw crushers are better suited for lighter, less demanding operations such as recycling and aggregates processing where simplicity, lower maintenance, and higher throughput are prioritized. Your choice should align with the material hardness, production requirements, and operational conditions to maximize efficiency and longevity.

Advantages and Disadvantages

Double toggle jaw crushers offer increased durability and higher crushing force, making them ideal for processing harder and abrasive materials. Single toggle jaw crushers are simpler in design, lighter, and require less maintenance but may face limitations with heavy-duty tasks due to reduced stroke length and lower crushing power. You should consider the specific application requirements and material hardness to choose between the reliable, robust double toggle and the efficient, cost-effective single toggle models.

Conclusion and Selection Guide

Double toggle jaw crushers deliver higher crushing force and are suitable for heavy-duty applications with harder materials, while single toggle crushers are lighter, more compact, and better for softer materials or smaller-scale operations. Choosing between them depends on factors like feed size, desired throughput, maintenance capacity, and operational efficiency. Prioritize double toggle crushers for durability and tough jobs, and single toggle crushers for simplicity and lower initial investment.

Double Toggle Jaw Crusher vs Single Toggle Jaw Crusher Infographic

libmatt.com

libmatt.com