A precalciner initiates the calcination process by partially heating raw materials before they enter the main kiln, enhancing energy efficiency and improving product quality. Your choice between a precalciner and a standard calciner depends on factors like fuel consumption, process control, and the specific material characteristics you need to process.

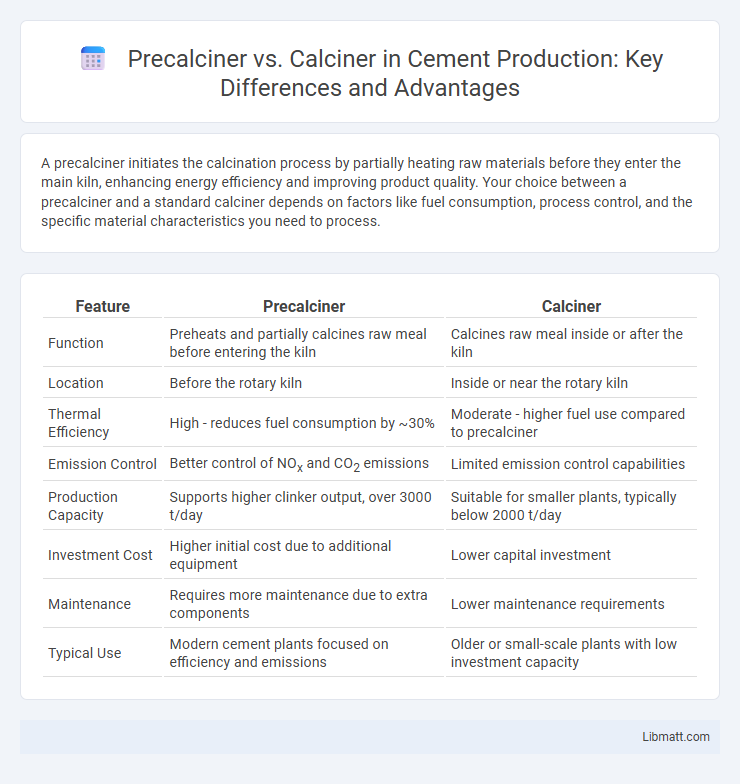

Table of Comparison

| Feature | Precalciner | Calciner |

|---|---|---|

| Function | Preheats and partially calcines raw meal before entering the kiln | Calcines raw meal inside or after the kiln |

| Location | Before the rotary kiln | Inside or near the rotary kiln |

| Thermal Efficiency | High - reduces fuel consumption by ~30% | Moderate - higher fuel use compared to precalciner |

| Emission Control | Better control of NOx and CO2 emissions | Limited emission control capabilities |

| Production Capacity | Supports higher clinker output, over 3000 t/day | Suitable for smaller plants, typically below 2000 t/day |

| Investment Cost | Higher initial cost due to additional equipment | Lower capital investment |

| Maintenance | Requires more maintenance due to extra components | Lower maintenance requirements |

| Typical Use | Modern cement plants focused on efficiency and emissions | Older or small-scale plants with low investment capacity |

Introduction to Precalciners and Calciners

Precalciners and calciners are essential components in cement production, designed to heat raw materials to high temperatures for chemical transformations. A precalciner serves as a combustion chamber where a significant portion of the raw material's calcination occurs before entering the kiln, enhancing fuel efficiency and boosting production rates. Your choice between a precalciner and a traditional calciner impacts energy consumption, throughput, and overall plant performance.

Key Differences Between Precalciner and Calciner

The key differences between a precalciner and a calciner lie in their stages within the cement production process and their roles in fuel efficiency and temperature control. A precalciner operates before the kiln, partially calcining raw meal by burning a large portion of fuel separately, enhancing energy efficiency and reducing kiln load. In contrast, a calciner is part of the kiln system, completing the calcination process at high temperatures, directly influencing clinker quality and kiln operation stability.

Working Principle of a Precalciner

A precalciner operates by heating raw meal with hot gases to initiate the calcination process before entering the kiln, effectively decomposing calcium carbonate into calcium oxide and carbon dioxide. This separate combustion chamber enhances fuel efficiency and increases kiln throughput by allowing partial calcination outside the rotary kiln. Your cement production benefits from improved energy utilization and higher operational flexibility due to the precalciner's ability to handle variable fuel types and combustion conditions.

Operational Mechanism of a Traditional Calciner

A traditional calciner operates by heating raw materials, typically limestone, at high temperatures in a rotary kiln or stationary furnace to drive off carbon dioxide during calcination. Its operational mechanism relies on indirect heat transfer and prolonged retention times to ensure complete decomposition of calcium carbonate into calcium oxide. This process is energy-intensive and slower compared to modern precalciner systems, which enhance efficiency by introducing fuel and combustion air upstream for earlier calcination.

Energy Efficiency Comparison

Precalciners operate at higher temperatures and separate the calcination process from the kiln, resulting in improved fuel utilization and up to 30% energy savings compared to traditional calciners. The enhanced heat exchange in precalciners reduces thermal losses by preheating the raw meal before entering the kiln, increasing overall thermal efficiency. In contrast, calciners integrated within rotary kilns have lower energy efficiency due to combined processing and limited heat recovery capabilities.

Impact on Cement Production Process

Precalciner technology increases the efficiency and capacity of cement production by enabling a higher percentage of fuel combustion before the kiln, resulting in reduced energy consumption and faster clinker formation. In contrast, traditional calciners operate within the kiln, making the process slower and less energy-efficient due to incomplete fuel combustion and longer retention times. Your cement plant can achieve improved thermal efficiency and lower CO2 emissions by utilizing a precalciner, enhancing overall production performance.

Emission Control: Precalciner vs Calciner

Precalciners offer superior emission control compared to traditional calciners by enabling more efficient combustion and reduced CO2 and NOx emissions due to their external combustion zone design. Your cement plant benefits from lowered pollutant release through staged combustion and better temperature regulation in a precalciner system. Calciners without a precalciner stage often result in higher emissions because the calcination and combustion processes occur simultaneously, limiting emission control efficiency.

Advantages and Disadvantages of Precalciners

Precalciners improve energy efficiency by allowing fuel to be burned before the material enters the kiln, reducing fuel consumption and increasing throughput. They enhance combustion control and reduce emissions, but increase system complexity, capital costs, and maintenance requirements. Your choice depends on operational priorities, with precalciners favored for high-capacity and eco-friendly cement production.

Cost Implications and Installation Considerations

Precalciners generally offer lower operational costs by improving fuel efficiency and reducing energy consumption, but their initial installation can require substantial capital investment and complex integration within existing kiln systems. Calder installations are simpler and less expensive upfront, yet they often result in higher long-term fuel expenses due to lower thermal efficiency. You should weigh the balance between upfront capital costs and operational savings to determine the most cost-effective and feasible solution for your cement production facility.

Future Trends in Calcination Technology

Future trends in calcination technology emphasize enhanced energy efficiency and reduced emissions through advanced preheating systems and real-time process monitoring in precalciner kilns. Integration of artificial intelligence and machine learning optimizes temperature control and fuel consumption, significantly improving clinker quality in cement production. The development of modular and retrofittable calciner units supports sustainable industrial practices by enabling incremental upgrades aligned with environmental regulations.

Precalciner vs Calciner Infographic

libmatt.com

libmatt.com