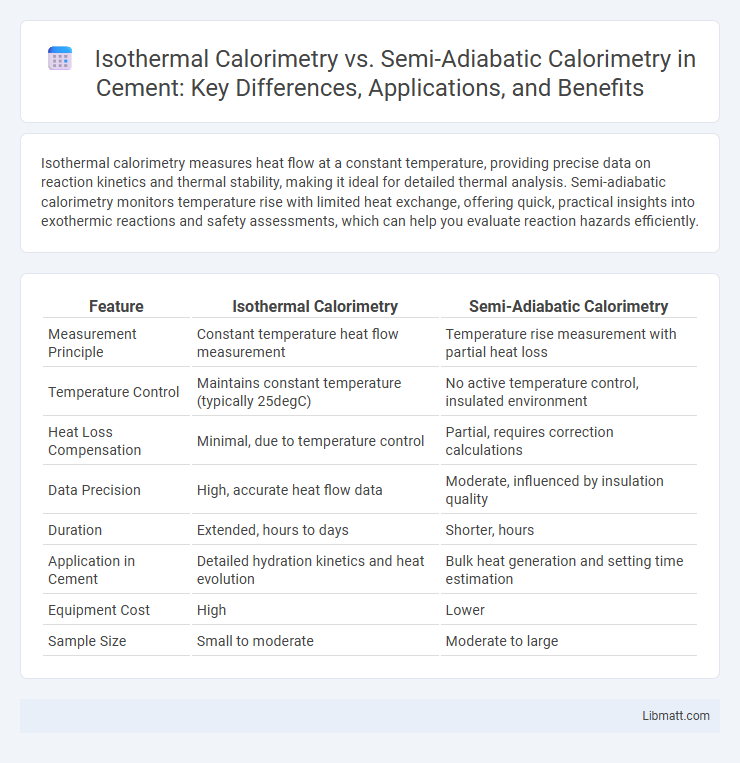

Isothermal calorimetry measures heat flow at a constant temperature, providing precise data on reaction kinetics and thermal stability, making it ideal for detailed thermal analysis. Semi-adiabatic calorimetry monitors temperature rise with limited heat exchange, offering quick, practical insights into exothermic reactions and safety assessments, which can help you evaluate reaction hazards efficiently.

Table of Comparison

| Feature | Isothermal Calorimetry | Semi-Adiabatic Calorimetry |

|---|---|---|

| Measurement Principle | Constant temperature heat flow measurement | Temperature rise measurement with partial heat loss |

| Temperature Control | Maintains constant temperature (typically 25degC) | No active temperature control, insulated environment |

| Heat Loss Compensation | Minimal, due to temperature control | Partial, requires correction calculations |

| Data Precision | High, accurate heat flow data | Moderate, influenced by insulation quality |

| Duration | Extended, hours to days | Shorter, hours |

| Application in Cement | Detailed hydration kinetics and heat evolution | Bulk heat generation and setting time estimation |

| Equipment Cost | High | Lower |

| Sample Size | Small to moderate | Moderate to large |

Introduction to Calorimetry Methods

Isothermal calorimetry measures heat flow at a constant temperature, enabling precise analysis of slow chemical and physical processes by maintaining thermal equilibrium between the sample and reference. Semi-adiabatic calorimetry, by contrast, allows some heat exchange with the surroundings, offering faster detection of exothermic reactions while tolerating slight temperature variations. Both methods provide critical insights into reaction kinetics and thermodynamics, with isothermal calorimetry favored for high sensitivity and semi-adiabatic used for rapid thermal event screening.

Principles of Isothermal Calorimetry

Isothermal calorimetry measures heat flow at a constant temperature, providing precise thermal data by maintaining a steady thermal environment around the sample. This technique is essential for studying reaction kinetics, phase transitions, and material stability under controlled conditions. Your analysis benefits from isothermal calorimetry's ability to deliver continuous, real-time heat measurements without temperature fluctuations affecting the results.

Fundamentals of Semi-Adiabatic Calorimetry

Semi-Adiabatic Calorimetry measures heat flow by allowing partial thermal exchange with the surroundings, offering a balance between fully insulated and fully open systems. It monitors temperature changes in the sample and reference, using insulation to reduce heat loss while permitting some heat dissipation. This method is valuable for studying reaction kinetics and thermal stability under controlled but not strictly isolated conditions.

Key Differences Between Isothermal and Semi-Adiabatic Calorimetry

Isothermal calorimetry measures heat flow at a constant temperature, providing precise data on reaction kinetics and stability by maintaining an equilibrium environment. Semi-adiabatic calorimetry records temperature rise in a nearly insulated system, enabling rapid detection of exothermic reactions but with less temperature control compared to isothermal methods. The key differences lie in temperature control precision, sensitivity to heat flow, and the typical application scope for thermal hazard evaluation versus detailed reaction analysis.

Accuracy and Sensitivity Comparison

Isothermal calorimetry offers superior accuracy and sensitivity by maintaining a constant temperature, allowing precise measurement of heat flow for subtle thermal events. Semi-adiabatic calorimetry, while useful for rapid screenings, generally has lower sensitivity due to slight temperature fluctuations that can introduce noise in heat detection. Your choice depends on the need for exact measurements in detailed studies, with isothermal calorimetry preferred for high-precision thermal analysis.

Applications in Material Science and Industry

Isothermal calorimetry measures heat flow at constant temperature, making it ideal for studying polymer curing, catalyst activity, and biochemical reactions in material science. Semi-adiabatic calorimetry detects temperature changes under near-adiabatic conditions, commonly applied in assessing battery safety, thermal stability of explosives, and exothermic reactions in chemical manufacturing. Both techniques provide critical data on reaction kinetics and material behavior, facilitating process optimization and safety evaluations in various industrial applications.

Data Interpretation and Output Analysis

Isothermal calorimetry provides continuous, high-resolution heat flow data allowing precise quantification of reaction kinetics and thermodynamic properties over time, facilitating detailed interpretation of steady-state processes. Semi-adiabatic calorimetry outputs temperature rise curves under quasi-adiabatic conditions, which require careful correction for heat loss to accurately analyze reaction rates and maximum heat release. Differences in data output formats necessitate distinct analytical approaches, with isothermal methods favoring real-time heat flow integration and semi-adiabatic techniques relying on temperature-time profiles for safety and scale-up assessments.

Advantages and Limitations of Each Technique

Isothermal calorimetry offers precise temperature control, enabling accurate measurement of heat flow under constant temperature conditions, which is ideal for studying slow or subtle thermal events, but it requires complex equipment and longer equilibrium times. Semi-adiabatic calorimetry allows for faster thermal analysis with simpler setup and is suited for screening exothermic reactions, yet it may suffer from less precise temperature control and potential heat loss, affecting data accuracy. Your choice between these techniques depends on whether sensitivity or speed is more critical for your thermal analysis needs.

Selection Criteria: Choosing the Right Calorimetry Method

Selecting the right calorimetry method depends on the thermal properties and behavior of your sample under investigation. Isothermal calorimetry offers precise heat flow measurements at a constant temperature, ideal for studying slow reactions or long-term stability, while semi-adiabatic calorimetry provides quicker detection of exothermic events and is suited for screening thermal hazards. Your choice should consider factors such as reaction kinetics, sensitivity requirements, and experimental time constraints to ensure accurate and relevant thermal analysis results.

Future Trends in Calorimetry Technologies

Future trends in calorimetry technologies emphasize enhanced sensitivity and miniaturization, with isothermal calorimetry advancing through integration with microfluidics for precise thermal analysis at microscale. Semi-adiabatic calorimetry is evolving with real-time data acquisition and improved thermal insulation to better monitor exothermic reactions in pharmaceutical and polymer industries. You can expect greater automation and AI-driven data interpretation to optimize thermal experiments and accelerate material development processes.

Isothermal Calorimetry vs Semi-Adiabatic Calorimetry Infographic

libmatt.com

libmatt.com