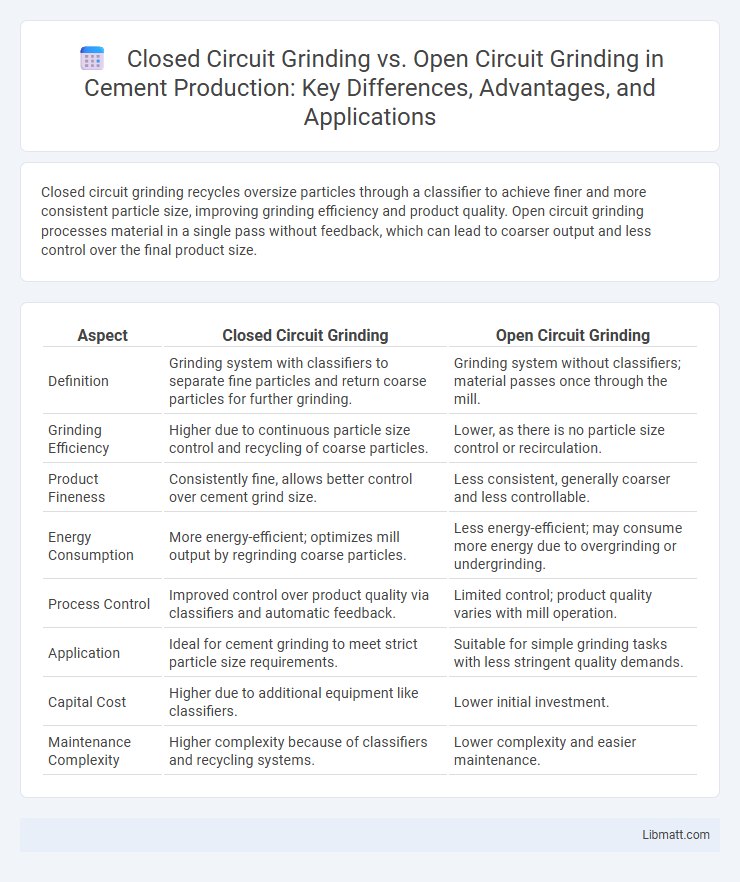

Closed circuit grinding recycles oversize particles through a classifier to achieve finer and more consistent particle size, improving grinding efficiency and product quality. Open circuit grinding processes material in a single pass without feedback, which can lead to coarser output and less control over the final product size.

Table of Comparison

| Aspect | Closed Circuit Grinding | Open Circuit Grinding |

|---|---|---|

| Definition | Grinding system with classifiers to separate fine particles and return coarse particles for further grinding. | Grinding system without classifiers; material passes once through the mill. |

| Grinding Efficiency | Higher due to continuous particle size control and recycling of coarse particles. | Lower, as there is no particle size control or recirculation. |

| Product Fineness | Consistently fine, allows better control over cement grind size. | Less consistent, generally coarser and less controllable. |

| Energy Consumption | More energy-efficient; optimizes mill output by regrinding coarse particles. | Less energy-efficient; may consume more energy due to overgrinding or undergrinding. |

| Process Control | Improved control over product quality via classifiers and automatic feedback. | Limited control; product quality varies with mill operation. |

| Application | Ideal for cement grinding to meet strict particle size requirements. | Suitable for simple grinding tasks with less stringent quality demands. |

| Capital Cost | Higher due to additional equipment like classifiers. | Lower initial investment. |

| Maintenance Complexity | Higher complexity because of classifiers and recycling systems. | Lower complexity and easier maintenance. |

Introduction to Grinding Circuits

Grinding circuits are essential components in mineral processing, designed to reduce ore particle size for efficient liberation of valuable minerals. Closed circuit grinding involves the use of classifiers or screens to separate fines from coarse particles, enabling repeated grinding of oversized material for improved size control and energy efficiency. Open circuit grinding processes material without classification, leading to a wider particle size distribution and typically higher energy consumption.

Definition of Closed Circuit Grinding

Closed circuit grinding is a process where the ground material is continuously monitored and recirculated through a classifier or screen to achieve a desired particle size before discharge. This system enhances efficiency by allowing only adequately sized particles to exit, while oversized material returns to the mill for further grinding. It contrasts with open circuit grinding, which lacks size classification and recirculation, often resulting in less uniform particle sizes and increased energy consumption.

Definition of Open Circuit Grinding

Open circuit grinding is a process where the material passes through the grinding mill only once without any return or recirculation for further grinding, resulting in a single-pass size reduction. This method is simpler and used for applications where precise particle size control is less critical. Your choice between open and closed circuit grinding impacts energy efficiency and product consistency in mineral processing.

Key Differences Between Closed and Open Circuit Grinding

Closed circuit grinding uses a classifier or separator to return oversized particles to the mill for further grinding, enhancing particle size control and efficiency. Open circuit grinding processes materials in the mill without recirculation, often resulting in less precise particle size distribution and higher energy consumption. The primary difference lies in the presence of a separation mechanism in closed circuit systems, optimizing throughput and product fineness compared to the simpler open circuit approach.

Advantages of Closed Circuit Grinding

Closed circuit grinding offers improved particle size control by recirculating oversized material back to the mill, resulting in more consistent product quality and higher efficiency. This method reduces energy consumption and grinding media wear by optimizing the milling process and minimizing overgrinding. You benefit from increased throughput and reduced operational costs with closed circuit grinding compared to open circuit configurations.

Advantages of Open Circuit Grinding

Open circuit grinding offers simplified operation with fewer process controls, resulting in lower maintenance costs and reduced equipment wear. Your production benefits from higher throughput rates and easier handling of varying feed sizes without the need for classification or recirculation loops. This method is particularly advantageous for coarse grinding applications where product size consistency is less critical.

Disadvantages and Limitations of Each System

Closed circuit grinding systems can be limited by the complexity of installation and maintenance since they require continuous monitoring and control of the classifier or separator to ensure optimal particle size distribution. Open circuit grinding systems often face disadvantages such as lower efficiency and increased energy consumption because the material passes through the mill only once, resulting in a broader particle size range and potential overgrinding. You should consider these limitations when selecting the appropriate grinding system for your specific mineral processing needs.

Applications in Mineral Processing Industry

Closed circuit grinding enhances particle size control by recirculating oversize material back to the mill, making it essential for optimizing ore liberation and improving downstream processing in mineral extraction. Open circuit grinding is typically applied where simplicity and lower capital investment are prioritized, such as in initial coarse grinding stages or when consistent feed size allows straightforward processing. In mineral processing, closed circuit systems are favored for fine grinding applications requiring precise size distribution to maximize flotation efficiency and metal recovery rates.

Factors Influencing Circuit Selection

Circuit selection between closed circuit grinding and open circuit grinding depends on factors such as desired product size, operational efficiency, and plant layout constraints. Closed circuit grinding is favored when strict control over particle size distribution and energy consumption is required, enabling recirculation of coarse material through a classifier or screen. Open circuit grinding is typically chosen for simpler operations or when downstream processes can handle variable product sizes, offering lower capital and maintenance costs.

Conclusion: Choosing the Optimal Grinding Circuit

Closed circuit grinding offers higher efficiency by recirculating oversized particles to the mill, resulting in finer product size and improved throughput. Open circuit grinding tends to have simpler operation but can lead to coarser product size and lower energy efficiency. Selecting the optimal grinding circuit depends on factors like desired product size, energy consumption, and overall milling process integration.

Closed Circuit Grinding vs Open Circuit Grinding Infographic

libmatt.com

libmatt.com