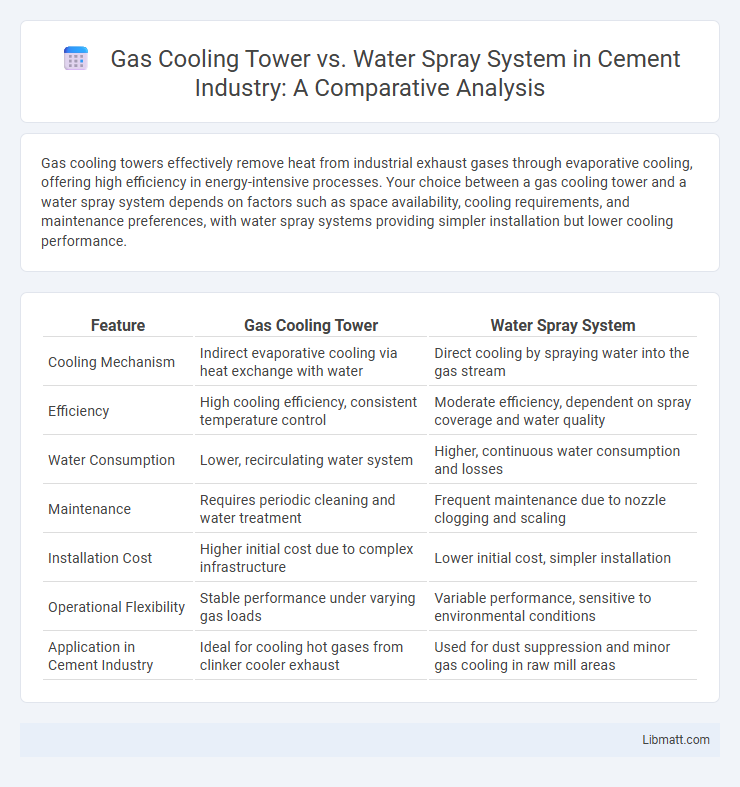

Gas cooling towers effectively remove heat from industrial exhaust gases through evaporative cooling, offering high efficiency in energy-intensive processes. Your choice between a gas cooling tower and a water spray system depends on factors such as space availability, cooling requirements, and maintenance preferences, with water spray systems providing simpler installation but lower cooling performance.

Table of Comparison

| Feature | Gas Cooling Tower | Water Spray System |

|---|---|---|

| Cooling Mechanism | Indirect evaporative cooling via heat exchange with water | Direct cooling by spraying water into the gas stream |

| Efficiency | High cooling efficiency, consistent temperature control | Moderate efficiency, dependent on spray coverage and water quality |

| Water Consumption | Lower, recirculating water system | Higher, continuous water consumption and losses |

| Maintenance | Requires periodic cleaning and water treatment | Frequent maintenance due to nozzle clogging and scaling |

| Installation Cost | Higher initial cost due to complex infrastructure | Lower initial cost, simpler installation |

| Operational Flexibility | Stable performance under varying gas loads | Variable performance, sensitive to environmental conditions |

| Application in Cement Industry | Ideal for cooling hot gases from clinker cooler exhaust | Used for dust suppression and minor gas cooling in raw mill areas |

Introduction to Gas Cooling Towers and Water Spray Systems

Gas cooling towers use air to remove heat from industrial processes by passing hot gas through a series of fill media, maximizing heat transfer and improving efficiency. Water spray systems cool gas streams by spraying fine water droplets directly into the gas flow, enhancing cooling through evaporation and direct contact. Your choice between these systems depends on factors like gas temperature, moisture content, and environmental regulations.

How Gas Cooling Towers Operate

Gas cooling towers operate by transferring heat from hot gases to the air through a process of evaporation and convection, using a large volume of air to cool the gases efficiently. The hot gases pass through wet fill material where water absorbs heat, then the cooled gas exits while warmed water is recirculated or discharged. Your industrial facility benefits from reduced gas temperatures and improved environmental compliance by installing an effective gas cooling tower system.

Working Principle of Water Spray Systems

Water spray systems operate by atomizing water into fine droplets that absorb heat through evaporation and convection, effectively cooling the surrounding gas or air. These systems rely on high-pressure pumps to distribute water via nozzles, ensuring optimal spray coverage and rapid temperature reduction. Your choice between gas cooling towers and water spray systems depends on factors such as cooling efficiency, installation space, and maintenance requirements.

Comparative Efficiency: Gas Cooling Tower vs Water Spray System

Gas cooling towers generally achieve higher thermal efficiency than water spray systems due to their enhanced heat transfer surface area and continuous cooling capacity. Water spray systems provide quicker temperature drops but suffer from lower cooling efficiency and higher water consumption, especially under hot, dry conditions. Operational costs for gas cooling towers tend to be lower over time, supported by improved energy savings and reduced water usage compared to water spray systems.

Energy Consumption and Operational Costs

Gas cooling towers typically consume less energy than water spray systems due to their efficient heat exchange processes, resulting in lower operational costs over time. Water spray systems require continuous pumping and large volumes of water, which increases both energy use and maintenance expenses. Your choice should consider long-term energy savings and cost efficiency, with gas cooling towers often offering a more economical solution in industrial cooling applications.

Environmental Impact and Water Usage

Gas cooling towers typically consume less water compared to water spray systems, reducing overall water usage and minimizing environmental strain. Water spray systems may cause higher water evaporation and potential chemical runoff, leading to greater environmental impact and contamination risks. Optimizing your cooling method involves balancing water efficiency with environmental preservation, choosing systems designed to minimize resource consumption and pollution.

Installation and Maintenance Requirements

Gas cooling towers require significant initial installation involving large structural support and precise alignment of fans and fill materials, while water spray systems are simpler to install with fewer mechanical components. Maintenance of gas cooling towers involves regular cleaning of fill media, inspection of mechanical parts, and water treatment to prevent scaling and microbial growth; water spray systems demand frequent nozzle cleaning and monitoring for clogging or corrosion. Your choice between these depends on balancing installation complexity and ongoing maintenance efforts suited to your operational needs.

Application Suitability and Industry Use Cases

Gas cooling towers excel in heavy industries such as power plants and chemical manufacturing where large-scale heat dissipation from gas streams is critical, providing efficient thermal management for combustion gases and process exhaust. Water spray systems are preferred in industries requiring localized cooling and dust suppression, including mining, steel production, and cement plants, due to their ability to rapidly lower temperatures and control particulate emissions. Both systems are essential for environmental compliance and operational efficiency, but gas cooling towers suit continuous, high-volume applications, while water spray systems are ideal for flexible, targeted cooling needs.

Advantages and Disadvantages of Each System

Gas cooling towers offer high efficiency in dissipating heat from industrial gases, providing energy savings and reduced environmental impact; however, they require significant maintenance and can be expensive to install. Water spray systems excel in rapid cooling and simplicity, making them cost-effective for lower temperature applications, but they may consume large water volumes and could cause wetting issues or corrosion over time. Selecting between the two depends on factors like operational costs, cooling requirements, water availability, and environmental regulations.

Choosing the Right Cooling Solution for Your Facility

Selecting between a gas cooling tower and a water spray system depends on factors such as facility size, cooling capacity, and environmental regulations. Gas cooling towers offer energy-efficient heat rejection for large-scale industrial processes, while water spray systems provide rapid cooling with lower initial costs for smaller or temporary setups. Evaluating operational costs, water availability, and maintenance requirements ensures the optimal cooling solution tailored to your facility's needs.

Gas Cooling Tower vs Water Spray System Infographic

libmatt.com

libmatt.com