Portland Limestone Cement (PLC) offers enhanced sustainability and reduced carbon emissions compared to Ordinary Portland Cement (OPC), making it an eco-friendly choice without compromising strength. Your construction projects benefit from improved durability and lower environmental impact when using PLC instead of traditional OPC.

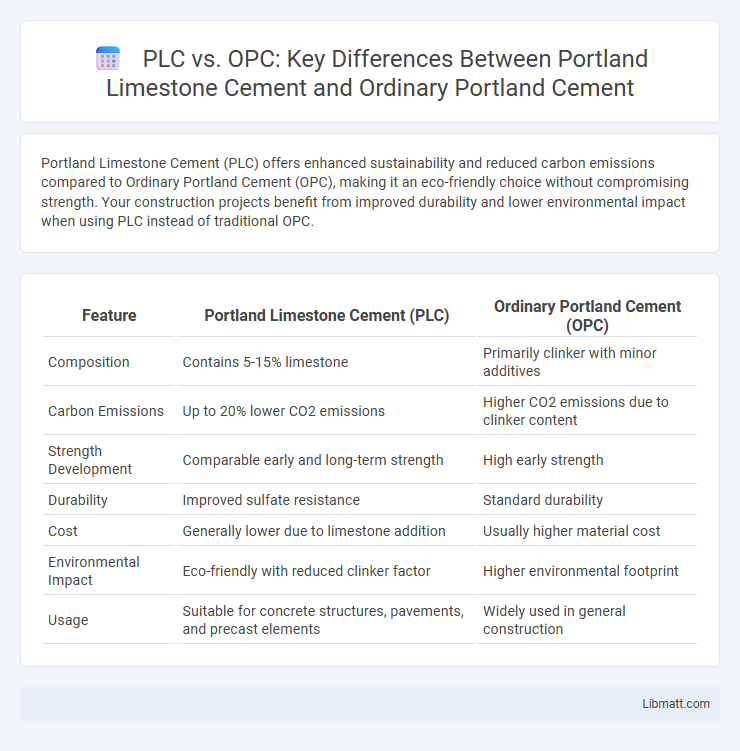

Table of Comparison

| Feature | Portland Limestone Cement (PLC) | Ordinary Portland Cement (OPC) |

|---|---|---|

| Composition | Contains 5-15% limestone | Primarily clinker with minor additives |

| Carbon Emissions | Up to 20% lower CO2 emissions | Higher CO2 emissions due to clinker content |

| Strength Development | Comparable early and long-term strength | High early strength |

| Durability | Improved sulfate resistance | Standard durability |

| Cost | Generally lower due to limestone addition | Usually higher material cost |

| Environmental Impact | Eco-friendly with reduced clinker factor | Higher environmental footprint |

| Usage | Suitable for concrete structures, pavements, and precast elements | Widely used in general construction |

Introduction to PLC and OPC

Portland Limestone Cement (PLC) incorporates a higher percentage of finely ground limestone, generally around 15%, compared to Ordinary Portland Cement (OPC), enhancing sustainability and reducing carbon emissions during production. OPC primarily consists of clinker and gypsum, known for its high strength and widespread use in conventional construction projects. Your choice between PLC and OPC can impact environmental footprint and early strength development, with PLC offering a greener alternative while maintaining similar performance characteristics.

Composition and Manufacturing Differences

Portland Limestone Cement (PLC) contains 5-15% finely ground limestone blended with traditional clinker and gypsum, whereas Ordinary Portland Cement (OPC) is primarily composed of clinker and gypsum without limestone addition. The manufacturing process of PLC involves mixing clinker with limestone during final grinding, reducing energy consumption and CO2 emissions compared to the higher clinker content in OPC production. PLC's lower clinker factor promotes enhanced sustainability while maintaining comparable strength and durability to OPC in construction applications.

Environmental Impact Comparison

Portland Limestone Cement (PLC) significantly reduces CO2 emissions compared to Ordinary Portland Cement (OPC) by incorporating up to 15% finely ground limestone, which lowers clinker content and energy consumption during production. This reduction in clinker not only decreases carbon footprint but also conserves natural resources, making PLC a more sustainable choice for environmentally conscious construction projects. Your choice of PLC can contribute to lowering greenhouse gas emissions and supporting global efforts toward sustainable building practices.

Mechanical Properties and Performance

Portland Limestone Cement (PLC) exhibits comparable mechanical properties to Ordinary Portland Cement (OPC) with improved durability and reduced carbon footprint. PLC typically achieves similar compressive strength development while enhancing resistance to sulfate attack and chloride ion penetration, beneficial for long-term structural performance. The incorporation of limestone in PLC also contributes to improved workability and reduced hydration heat, optimizing performance in various construction applications.

Workability and Application Areas

Portland Limestone Cement (PLC) offers improved workability compared to Ordinary Portland Cement (OPC) due to its finer particle size and the presence of limestone, enhancing plasticity and ease of placement. PLC is well-suited for applications such as concrete pavements, precast elements, and mass concrete structures where reduced heat of hydration and better durability are critical. OPC remains preferred in high-strength and rapid-setting applications where early strength gain is essential.

Durability and Longevity

Portland Limestone Cement (PLC) enhances durability by incorporating finely ground limestone, which improves resistance to sulfate attacks and reduces permeability compared to Ordinary Portland Cement (OPC). PLC's lower clinker content results in decreased heat of hydration, minimizing thermal cracking and extending the lifespan of concrete structures. Studies indicate that structures made with PLC maintain mechanical strength and durability over time, offering sustainable longevity benefits in various construction applications.

Cost Analysis: PLC vs OPC

Portland Limestone Cement (PLC) generally offers cost advantages compared to Ordinary Portland Cement (OPC) due to reduced clinker content, which lowers production expenses and energy consumption. The use of limestone as a filler material in PLC reduces raw material costs while maintaining comparable performance, making it a more economical choice for large-scale construction projects. When evaluating your project budget, choosing PLC can result in substantial savings without compromising durability or strength.

Standards and Regulatory Compliance

Portland Limestone Cement (PLC) meets stringent standards such as ASTM C595 and EN 197-1, ensuring regulatory compliance while offering reduced carbon emissions compared to Ordinary Portland Cement (OPC), which conforms primarily to ASTM C150 and EN 197-1 standards. PLC incorporates up to 15% finely ground limestone, enabling compliance with sustainability requirements without compromising strength or durability. Regulatory bodies increasingly endorse PLC as a greener alternative, aligning construction practices with environmental regulations and carbon reduction targets.

Market Adoption and Availability

Portland Limestone Cement (PLC) is gaining market adoption due to its lower carbon footprint and enhanced sustainability compared to Ordinary Portland Cement (OPC), making it increasingly popular in green construction projects. While OPC remains widely available and dominates global markets, PLC availability is expanding as manufacturers adapt to environmental regulations and consumer demand for eco-friendly materials. The growing infrastructure investments in regions such as Europe and North America are accelerating PLC distribution, yet OPC retains a strong presence, especially in developing markets with established supply chains.

Future Trends in Cement Technology

Portland Limestone Cement (PLC) is revolutionizing the cement industry by reducing carbon emissions by up to 20% compared to Ordinary Portland Cement (OPC) through lower clinker content and enhanced use of limestone. Future trends indicate a growing adoption of PLC driven by stricter environmental regulations and demand for sustainable construction materials that maintain comparable strength and durability to OPC. Innovations such as blending with supplementary cementitious materials (SCMs) and advancements in clinker production efficiency further position PLC as a key component in low-carbon cement technology.

PLC (Portland Limestone Cement) vs OPC Infographic

libmatt.com

libmatt.com