Preventive maintenance involves scheduled inspections and servicing based on time or usage intervals to reduce the risk of equipment failure, while predictive maintenance uses real-time data and condition-monitoring technologies to forecast potential issues before they occur. Your maintenance strategy can benefit from predictive maintenance by optimizing downtime and extending asset lifespan with data-driven decision-making.

Table of Comparison

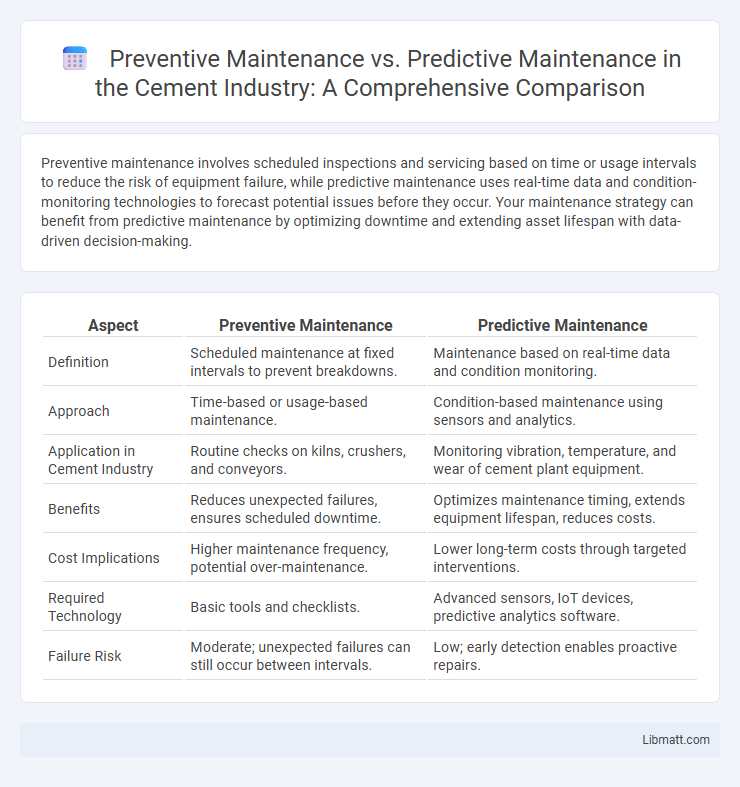

| Aspect | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance at fixed intervals to prevent breakdowns. | Maintenance based on real-time data and condition monitoring. |

| Approach | Time-based or usage-based maintenance. | Condition-based maintenance using sensors and analytics. |

| Application in Cement Industry | Routine checks on kilns, crushers, and conveyors. | Monitoring vibration, temperature, and wear of cement plant equipment. |

| Benefits | Reduces unexpected failures, ensures scheduled downtime. | Optimizes maintenance timing, extends equipment lifespan, reduces costs. |

| Cost Implications | Higher maintenance frequency, potential over-maintenance. | Lower long-term costs through targeted interventions. |

| Required Technology | Basic tools and checklists. | Advanced sensors, IoT devices, predictive analytics software. |

| Failure Risk | Moderate; unexpected failures can still occur between intervals. | Low; early detection enables proactive repairs. |

Introduction to Maintenance Strategies

Preventive maintenance involves scheduled inspections and servicing based on time intervals or usage cycles to reduce equipment failure. Predictive maintenance utilizes real-time data and condition monitoring technologies to anticipate failures before they occur, optimizing maintenance timing. Your choice between these strategies impacts operational efficiency, downtime, and maintenance costs significantly.

Understanding Preventive Maintenance

Preventive maintenance involves scheduled inspections and routine servicing based on time or usage intervals to reduce equipment failure and extend asset lifespan. This approach relies on historical data and manufacturer recommendations to perform tasks before breakdowns occur, minimizing unplanned downtime. Implementing preventive maintenance can improve reliability and safety while ensuring consistent operational efficiency across industrial systems.

Key Features of Predictive Maintenance

Predictive maintenance leverages advanced data analytics, machine learning algorithms, and real-time sensor data to forecast equipment failures before they occur, enabling targeted interventions that reduce downtime and maintenance costs. Key features include continuous condition monitoring, trend analysis of equipment performance, and automated alerts for anomaly detection. This approach contrasts with preventive maintenance, which relies on scheduled inspections and routine servicing regardless of actual equipment condition.

Differences Between Preventive and Predictive Maintenance

Preventive maintenance involves scheduled inspections and routine servicing based on time or usage intervals to reduce equipment failure risks, while predictive maintenance uses real-time data and condition-monitoring tools to assess equipment health and predict failures. Preventive maintenance follows a fixed schedule regardless of equipment condition, whereas predictive maintenance dynamically optimizes maintenance actions by analyzing sensor data, vibration analysis, and machine learning algorithms. Predictive maintenance offers higher efficiency and cost savings by addressing potential issues before failure, contrasting with the more generalized approach of preventive maintenance.

Benefits of Preventive Maintenance

Preventive maintenance reduces equipment downtime by scheduling regular inspections and servicing, preventing costly breakdowns before they occur. It extends the lifespan of machinery, ensuring consistent performance and enhancing safety in your operations. You benefit from lower repair costs and improved asset reliability through systematic upkeep.

Advantages of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to accurately forecast equipment failures, reducing unplanned downtime and optimizing maintenance schedules. This approach enhances asset lifespan by addressing issues before they escalate, leading to cost savings in repairs and operational efficiency. Unlike preventive maintenance, predictive strategies minimize unnecessary interventions, conserving resources and maximizing productivity.

Challenges in Implementation

Preventive maintenance faces challenges such as scheduling disruptions and unnecessary part replacements, leading to increased downtime and costs. Predictive maintenance implementation requires advanced sensor technology, data analytics expertise, and substantial initial investment, which can be barriers for many organizations. You must balance these challenges by aligning maintenance strategies with operational goals and available resources to optimize asset performance.

Cost Comparison: Preventive vs Predictive Maintenance

Preventive maintenance typically incurs higher routine costs due to scheduled inspections and part replacements regardless of equipment condition, while predictive maintenance reduces expenses by using real-time data and condition monitoring to address issues only when necessary. Predictive maintenance leverages IoT sensors and machine learning algorithms, leading to lower labor costs and minimized unplanned downtime. Improved accuracy in failure prediction significantly optimizes maintenance budgets and extends asset lifespan compared to preventive methods.

Industry Applications and Case Studies

Preventive maintenance, widely used in manufacturing and facility management, relies on scheduled inspections to reduce equipment downtime, while predictive maintenance leverages IoT sensors and data analytics in industries like aerospace and energy for real-time condition monitoring. Case studies reveal that companies utilizing predictive maintenance, such as General Electric with their jet engines, achieve up to 20% cost savings and 40% reduction in unplanned downtime compared to traditional preventive methods. Your organization can enhance asset lifespan and operational efficiency by integrating predictive maintenance strategies tailored to industry-specific requirements.

Choosing the Right Maintenance Approach

Choosing the right maintenance approach depends on factors such as equipment criticality, available data, and cost efficiency. Preventive maintenance schedules inspections and replacements based on time or usage intervals, reducing unexpected failures in less complex systems. Predictive maintenance leverages real-time sensor data and analytics to forecast failures, optimizing maintenance actions for high-value assets and minimizing downtime.

Preventive Maintenance vs Predictive Maintenance Infographic

libmatt.com

libmatt.com