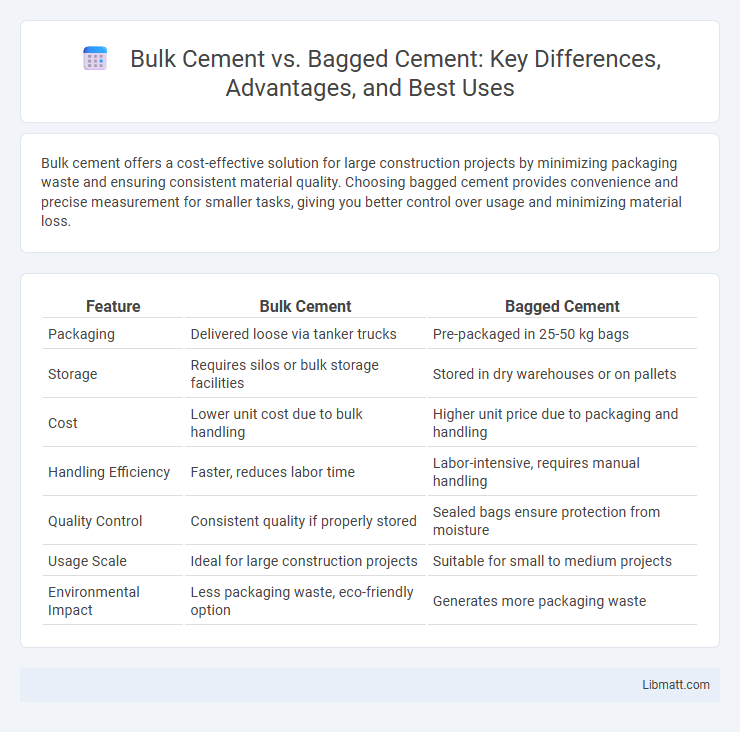

Bulk cement offers a cost-effective solution for large construction projects by minimizing packaging waste and ensuring consistent material quality. Choosing bagged cement provides convenience and precise measurement for smaller tasks, giving you better control over usage and minimizing material loss.

Table of Comparison

| Feature | Bulk Cement | Bagged Cement |

|---|---|---|

| Packaging | Delivered loose via tanker trucks | Pre-packaged in 25-50 kg bags |

| Storage | Requires silos or bulk storage facilities | Stored in dry warehouses or on pallets |

| Cost | Lower unit cost due to bulk handling | Higher unit price due to packaging and handling |

| Handling Efficiency | Faster, reduces labor time | Labor-intensive, requires manual handling |

| Quality Control | Consistent quality if properly stored | Sealed bags ensure protection from moisture |

| Usage Scale | Ideal for large construction projects | Suitable for small to medium projects |

| Environmental Impact | Less packaging waste, eco-friendly option | Generates more packaging waste |

Introduction to Bulk Cement and Bagged Cement

Bulk cement refers to cement delivered and stored in large quantities using specialized tankers and silos, ensuring efficient handling for large construction projects. Bagged cement is pre-packaged in standardized bags, typically in 50 kg units, providing ease of transport and controlled usage for smaller or varied construction tasks. The choice between bulk and bagged cement depends on project scale, storage capacity, and site requirements, impacting cost-effectiveness and logistics.

Composition and Packaging Differences

Bulk cement is typically stored and transported in large silos or tankers, allowing for easy delivery in massive quantities, while bagged cement is packaged in standard-sized bags, usually 50 kg each, for smaller-scale use and easier handling. The composition of bulk and bagged cement remains consistent, primarily consisting of clinker, gypsum, and other additives, but the bulk form often undergoes stricter quality control to prevent contamination during transport. Your choice between bulk and bagged cement depends on project scale and storage capabilities, with bulk cement favored for large construction projects due to efficiency in handling and reduced packaging waste.

Storage Requirements for Bulk vs Bagged Cement

Bulk cement requires specialized storage silos equipped with moisture control systems to prevent clumping and degradation, maintaining cement quality during long-term storage. Bagged cement demands dry, well-ventilated warehouses with pallets to avoid moisture absorption and contamination, limiting storage duration compared to bulk cement. Proper storage conditions for both types are critical to preserving cement strength and ensuring optimal performance in construction projects.

Transportation and Handling Considerations

Bulk cement transportation requires specialized tanker trucks and pneumatic systems for efficient loading and unloading, minimizing contamination and moisture exposure during transit. Bagged cement offers flexibility in handling and smaller delivery volumes using standard vehicles but increases labor intensity due to manual loading and unloading processes. Proper moisture control and storage conditions are critical for both forms to maintain cement quality and prevent clumping or degradation.

Cost Comparison: Bulk vs Bagged Cement

Bulk cement typically offers a lower cost per ton compared to bagged cement due to reduced packaging and handling expenses. Transporting bulk cement in large quantities minimizes labor and material costs, translating to savings for large construction projects. You can reduce overall project expenses by choosing bulk cement when high volumes are required, whereas bagged cement suits smaller jobs despite its higher price per unit.

Quality Control and Consistency

Bulk cement offers superior quality control and consistency due to centralized storage and handling systems that minimize contamination and moisture exposure, ensuring uniform cement properties. Bagged cement, although convenient for smaller projects, is more susceptible to variations in quality caused by improper storage, handling, and transportation, leading to potential discrepancies in strength and performance. Consistent production monitoring and controlled bulk delivery systems make bulk cement a preferred choice for large-scale construction requiring reliable material standards.

Environmental Impact and Sustainability

Bulk cement significantly reduces packaging waste, lowering the environmental footprint compared to bagged cement, which requires additional materials like paper or plastic bags that contribute to landfill waste. The transportation efficiency of bulk cement also decreases carbon emissions per ton, as it allows for larger quantities to be moved in fewer trips. Sustainable construction trends increasingly favor bulk cement for its resource efficiency and reduced environmental impact throughout the supply chain.

Project Scale Suitability

Bulk cement is ideal for large-scale construction projects such as infrastructure developments, commercial buildings, and industrial sites due to its efficient handling and cost-effectiveness. Bagged cement offers greater flexibility and is better suited for small to medium-sized projects or repairs where precise quantities and ease of transport are critical. Choosing between bulk and bagged cement depends on the project scale, with bulk cement minimizing waste and labor costs in large volumes, while bagged cement supports controlled use in smaller, detail-specific applications.

Common Applications and Use Cases

Bulk cement is ideal for large-scale construction projects such as commercial buildings, infrastructure, and industrial facilities due to its efficient on-site storage and reduced handling costs. Bagged cement suits smaller projects like residential repairs, masonry work, and DIY tasks where precise quantities and easy transport are essential. Choosing between bulk and bagged cement depends on your project's size, storage capacity, and application requirements.

Choosing the Right Cement Option for Your Project

Choosing between bulk cement and bagged cement depends on the scale and specific needs of your project. Bulk cement is ideal for large construction sites due to its cost-effectiveness, reduced packaging waste, and ease of storage in silos, while bagged cement suits smaller projects or locations with limited storage space, offering convenience and precise quantity control. Evaluating project size, storage capacity, and budget will help determine the most efficient and economical cement option for your construction goals.

Bulk cement vs Bagged cement Infographic

libmatt.com

libmatt.com