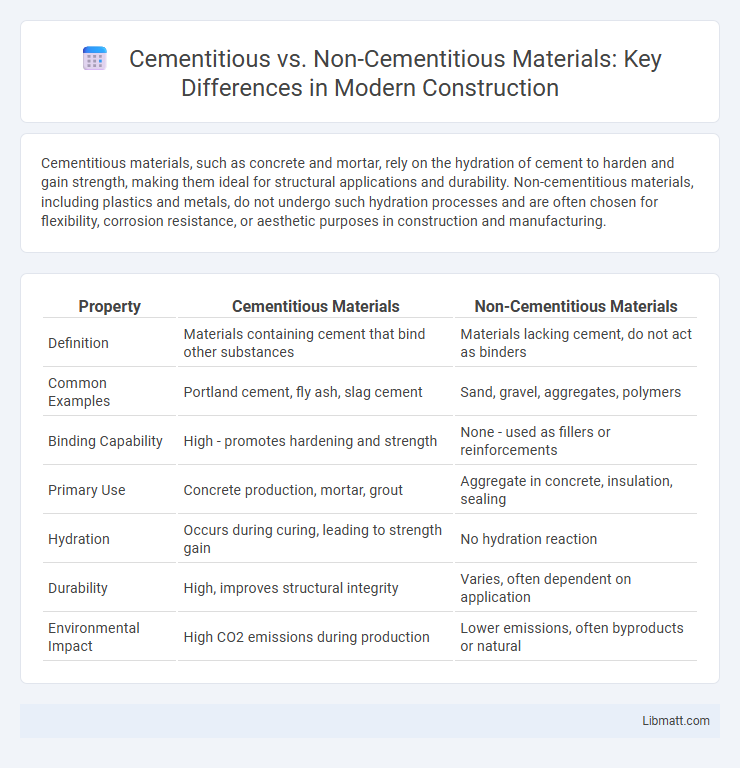

Cementitious materials, such as concrete and mortar, rely on the hydration of cement to harden and gain strength, making them ideal for structural applications and durability. Non-cementitious materials, including plastics and metals, do not undergo such hydration processes and are often chosen for flexibility, corrosion resistance, or aesthetic purposes in construction and manufacturing.

Table of Comparison

| Property | Cementitious Materials | Non-Cementitious Materials |

|---|---|---|

| Definition | Materials containing cement that bind other substances | Materials lacking cement, do not act as binders |

| Common Examples | Portland cement, fly ash, slag cement | Sand, gravel, aggregates, polymers |

| Binding Capability | High - promotes hardening and strength | None - used as fillers or reinforcements |

| Primary Use | Concrete production, mortar, grout | Aggregate in concrete, insulation, sealing |

| Hydration | Occurs during curing, leading to strength gain | No hydration reaction |

| Durability | High, improves structural integrity | Varies, often dependent on application |

| Environmental Impact | High CO2 emissions during production | Lower emissions, often byproducts or natural |

Introduction to Cementitious and Non-Cementitious Materials

Cementitious materials such as Portland cement, fly ash, and slag are characterized by their ability to harden and gain strength through a hydration process when mixed with water. Non-cementitious materials like lime, gypsum, and clay do not rely on hydration for setting but often set through chemical or physical reactions such as carbonation or drying. Understanding the distinct chemical compositions and setting mechanisms of cementitious versus non-cementitious materials is crucial for selecting appropriate building materials in construction and engineering applications.

Defining Cementitious Materials

Cementitious materials are substances that harden and bind other materials through a chemical reaction with water, primarily including Portland cement, fly ash, and slag. These materials undergo a hydration process that forms strong, durable bonds essential for construction applications such as concrete and mortar. Non-cementitious materials, by contrast, do not rely on hydration but may use mechanical bonding or chemical adhesion for their structural properties.

Key Characteristics of Cementitious Materials

Cementitious materials are characterized by their ability to harden and gain strength through hydration reactions with water, primarily consisting of compounds like calcium silicates. These materials exhibit high compressive strength, durability, and excellent adhesive properties, making them essential in construction as binders in concrete and mortar. Their porosity and microstructure significantly influence strength development, resistance to chemical attack, and overall performance in various environmental conditions.

Understanding Non-Cementitious Materials

Non-cementitious materials refer to construction substances that do not contain cement as a binding agent, including natural stones, lime-based mortars, clay, and polymers. These materials offer varying properties such as flexibility, breathability, and environmental sustainability, making them suitable for specialized applications like historic building restoration and eco-friendly construction. Understanding the composition and performance of non-cementitious materials is essential for selecting appropriate alternatives to traditional cementitious products in modern construction projects.

Core Properties of Non-Cementitious Materials

Non-cementitious materials exhibit core properties such as flexibility, lightweight composition, and enhanced resistance to chemical corrosion compared to cementitious counterparts. These materials often provide superior thermal insulation and improved durability in environments where moisture and harsh chemicals degrade cementitious substances. By choosing non-cementitious options, Your construction projects can benefit from reduced cracking and prolonged structural integrity.

Common Applications of Cementitious Materials

Cementitious materials, including Portland cement, fly ash, and slag, are commonly used in construction for creating concrete, mortar, and grout, providing structural strength and durability. These materials are essential in applications such as building foundations, bridges, roads, and precast concrete products, where long-lasting and load-bearing properties are critical. Your projects benefit from the reliable performance and versatility of cementitious materials in both residential and commercial construction.

Typical Uses of Non-Cementitious Materials

Non-cementitious materials are commonly used in applications requiring flexibility, lightweight properties, and resistance to chemical corrosion, such as in insulation, membrane waterproofing, and decorative finishes. These materials include polymers, bituminous compounds, and gypsum, which are often utilized in roofing, flooring, and as sealants in construction projects. Their ability to provide thermal and acoustic insulation makes them essential in both residential and commercial building environments.

Performance Comparison: Strength, Durability, and Flexibility

Cementitious materials typically exhibit higher compressive strength and durability due to their hydraulic binding properties that enhance resistance to environmental factors like moisture and chemical exposure. Non-cementitious materials, such as polymers or recycled composites, often offer superior flexibility and tensile strength, making them ideal for applications requiring deformation tolerance and crack resistance. The performance comparison highlights cementitious materials' dominance in structural load-bearing and longevity, whereas non-cementitious alternatives excel in adaptable and resilient design solutions.

Environmental Impact: Sustainability and Carbon Footprint

Cementitious materials, primarily Portland cement, contribute significantly to global CO2 emissions, accounting for approximately 8% of total anthropogenic carbon dioxide output due to calcination and fossil fuel combustion during production. Non-cementitious materials, such as geopolymers and lime-based binders, offer lower embodied carbon by utilizing industrial by-products like fly ash and slag, enhancing sustainability through resource efficiency and reduced greenhouse gas emissions. Adopting non-cementitious alternatives in construction can reduce the carbon footprint of infrastructure projects, supporting global climate goals and advancing circular economy principles.

Choosing the Right Material: Factors to Consider

Choosing the right material between cementitious and non-cementitious options depends on factors such as durability, application environment, and compatibility with existing structures. Cementitious materials offer superior bonding strength and are ideal for load-bearing applications, while non-cementitious materials provide better flexibility and resistance to chemical exposure. Your decision should also consider cost-effectiveness and the required curing time to ensure optimal performance.

Cementitious vs Non-Cementitious Materials Infographic

libmatt.com

libmatt.com