Low alkali cement reduces the risk of alkali-silica reaction (ASR) in concrete, enhancing durability and preventing cracking compared to ordinary Portland cement. Your choice between the two should depend on the specific requirements of your construction project and the environmental conditions involved.

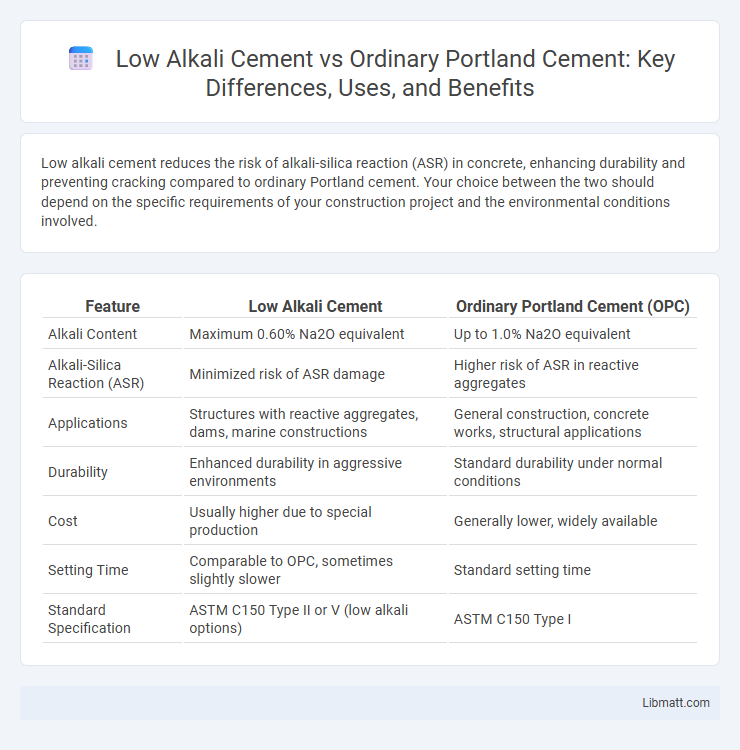

Table of Comparison

| Feature | Low Alkali Cement | Ordinary Portland Cement (OPC) |

|---|---|---|

| Alkali Content | Maximum 0.60% Na2O equivalent | Up to 1.0% Na2O equivalent |

| Alkali-Silica Reaction (ASR) | Minimized risk of ASR damage | Higher risk of ASR in reactive aggregates |

| Applications | Structures with reactive aggregates, dams, marine constructions | General construction, concrete works, structural applications |

| Durability | Enhanced durability in aggressive environments | Standard durability under normal conditions |

| Cost | Usually higher due to special production | Generally lower, widely available |

| Setting Time | Comparable to OPC, sometimes slightly slower | Standard setting time |

| Standard Specification | ASTM C150 Type II or V (low alkali options) | ASTM C150 Type I |

Introduction to Cement Types

Low alkali cement contains reduced alkali content, minimizing chemical reactions with aggregates that cause concrete deterioration, making it ideal for environments with reactive aggregates. Ordinary Portland Cement (OPC) is the most common cement type, valued for its versatility and strength in general construction projects. Your choice between these cement types impacts durability and performance depending on specific project requirements and environmental conditions.

What is Ordinary Portland Cement (OPC)?

Ordinary Portland Cement (OPC) is a widely used type of cement in construction made by grinding clinker with gypsum to achieve desired setting properties. It primarily consists of calcium silicates, which react with water to form a hard, durable material suitable for various structural applications. Your choice of OPC depends on strength grades like 33, 43, or 53, indicating compressive strength in megapascals after 28 days.

Understanding Low Alkali Cement

Low Alkali Cement contains significantly lower alkali content, typically below 0.6%, reducing the risk of alkali-silica reaction (ASR) in concrete structures. Ordinary Portland Cement usually has higher alkali levels, which can lead to durability issues like cracking when reactive aggregates are present. Understanding Low Alkali Cement helps you select materials that enhance the longevity and structural integrity of your concrete projects.

Key Chemical Composition Differences

Low Alkali Cement contains significantly lower sodium oxide (Na2O) and potassium oxide (K2O) levels, typically below 0.6%, compared to Ordinary Portland Cement which often has alkali oxide content exceeding 1.0%. The reduced alkali content in Low Alkali Cement minimizes alkali-silica reaction (ASR) risks, important for enhancing durability in concrete exposed to reactive aggregates. Your choice between these cements depends on the chemical environment and the need to control potential expansive reactions affecting structural integrity.

Production Process Comparison

Low Alkali Cement is produced using raw materials with reduced alkali content and often incorporates supplementary cementitious materials (SCMs) like fly ash or slag to limit alkali levels, which helps reduce the risk of alkali-silica reaction in concrete. Ordinary Portland Cement (OPC) is manufactured mainly from clinker made by heating limestone and clay at high temperatures, without specific control over alkali content, resulting in higher sodium and potassium levels. The production process of Low Alkali Cement involves stricter raw material selection and blending practices compared to OPC to achieve the desired low alkali thresholds, typically below 0.6% Na2O equivalent.

Performance Characteristics

Low Alkali Cement demonstrates superior resistance to alkali-silica reaction (ASR), reducing the risk of concrete degradation in environments with reactive aggregates, while Ordinary Portland Cement (OPC) is more susceptible to such issues. The lower alkali content in Low Alkali Cement improves durability and enhances long-term structural integrity, particularly in harsh or moisture-rich conditions. Your choice of Low Alkali Cement can significantly improve performance in projects requiring high durability and minimal chemical reactivity.

Advantages of Low Alkali Cement

Low Alkali Cement offers significant advantages in preventing alkali-silica reaction (ASR), which enhances durability and reduces cracking in concrete structures. Its lower alkali content minimizes the risk of chemical reactions with reactive aggregates, making it ideal for constructions exposed to moisture or harsh environments. Using Low Alkali Cement in Your projects ensures longer lifespan and improved structural integrity compared to Ordinary Portland Cement.

Limitations of Ordinary Portland Cement

Ordinary Portland Cement (OPC) poses limitations such as increased susceptibility to alkali-silica reaction (ASR), which can cause concrete expansion and cracking over time, reducing structural durability. OPC often leads to higher heat generation during hydration, making it less suitable for massive concrete pours due to thermal stresses. You may require Low Alkali Cement to mitigate these issues, especially in environments prone to chemical reactions or where long-term durability is critical.

Applications and Suitability

Low Alkali Cement is ideal for concrete structures exposed to sulfate-rich environments, minimizing alkali-silica reaction and enhancing durability in sewage treatment plants and marine constructions. Ordinary Portland Cement suits general construction projects like residential buildings and roads where high alkali content does not pose significant risks. Your choice depends on environmental conditions and long-term structural performance requirements.

Summary: Choosing the Right Cement

Low alkali cement reduces the risk of alkali-silica reaction (ASR), making it ideal for structures exposed to reactive aggregates or high moisture environments. Ordinary Portland cement offers versatility and cost-effectiveness for general construction where ASR risk is low. Selecting the appropriate cement depends on project-specific conditions like exposure to chemicals, durability requirements, and aggregate reactivity.

Low Alkali Cement vs Ordinary Portland Cement Infographic

libmatt.com

libmatt.com