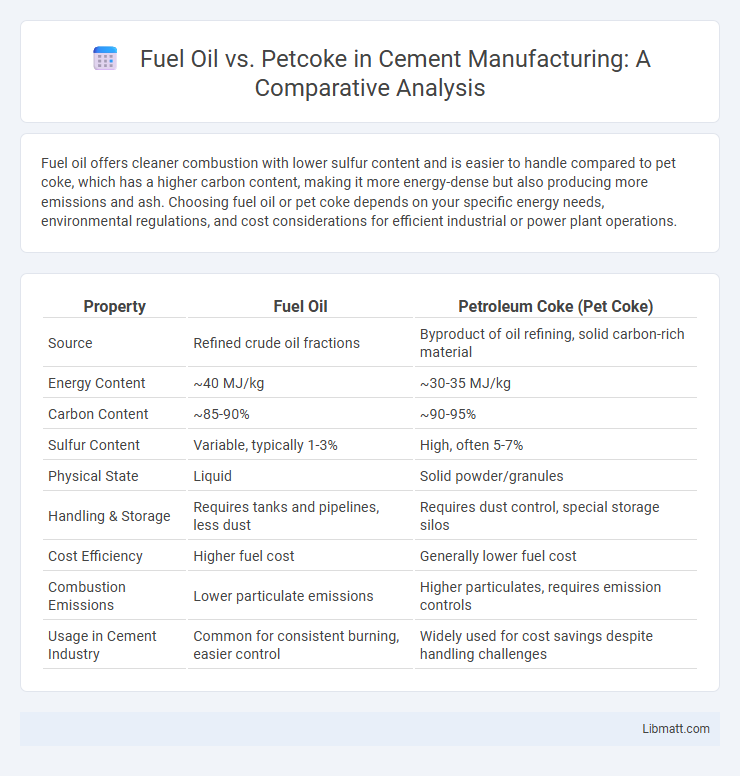

Fuel oil offers cleaner combustion with lower sulfur content and is easier to handle compared to pet coke, which has a higher carbon content, making it more energy-dense but also producing more emissions and ash. Choosing fuel oil or pet coke depends on your specific energy needs, environmental regulations, and cost considerations for efficient industrial or power plant operations.

Table of Comparison

| Property | Fuel Oil | Petroleum Coke (Pet Coke) |

|---|---|---|

| Source | Refined crude oil fractions | Byproduct of oil refining, solid carbon-rich material |

| Energy Content | ~40 MJ/kg | ~30-35 MJ/kg |

| Carbon Content | ~85-90% | ~90-95% |

| Sulfur Content | Variable, typically 1-3% | High, often 5-7% |

| Physical State | Liquid | Solid powder/granules |

| Handling & Storage | Requires tanks and pipelines, less dust | Requires dust control, special storage silos |

| Cost Efficiency | Higher fuel cost | Generally lower fuel cost |

| Combustion Emissions | Lower particulate emissions | Higher particulates, requires emission controls |

| Usage in Cement Industry | Common for consistent burning, easier control | Widely used for cost savings despite handling challenges |

Introduction to Fuel Oil and Pet Coke

Fuel oil, a refined petroleum product, is widely used for heating, power generation, and marine fuel due to its high energy content and relatively cleaner combustion compared to other fossil fuels. Pet coke, or petroleum coke, is a carbon-rich solid material derived from oil refining processes, primarily utilized in industrial applications like cement manufacturing and power plants for its high calorific value and low cost. Understanding the differences in composition, combustion properties, and environmental impact is essential for selecting the appropriate fuel in energy production and industrial sectors.

Chemical Composition: Fuel Oil vs Pet Coke

Fuel oil primarily consists of long-chain hydrocarbons with sulfur, nitrogen, and trace metals, resulting in a viscous liquid fuel used in combustion engines and industrial heating. Pet coke, or petroleum coke, is a solid carbon-rich material predominantly made of nearly pure carbon with minimal hydrogen and high levels of sulfur and heavy metals. The higher carbon content and lower volatility of pet coke lead to more carbonaceous emissions compared to the more liquid and variable hydrocarbon profile of fuel oil.

Energy Efficiency Comparison

Fuel oil typically offers higher energy efficiency than pet coke due to its cleaner combustion properties and higher calorific value, leading to more complete burning and less residue. Pet coke, though cheaper and with a higher carbon content, often results in lower thermal efficiency and increased emissions due to its higher sulfur and impurity levels. When optimizing Your energy consumption, choosing fuel oil can enhance operational performance and reduce environmental impact.

Environmental Impact and Emissions

Fuel oil typically produces lower sulfur dioxide (SO2) and particulate matter emissions compared to pet coke, which contains higher carbon and sulfur content, leading to increased greenhouse gas emissions and air pollution. Pet coke combustion releases more carbon dioxide (CO2) and heavy metals, significantly impacting air quality and contributing to acid rain and respiratory issues. Choosing fuel oil over pet coke can help reduce your environmental footprint by limiting toxic emissions and minimizing adverse health effects.

Cost Analysis: Fuel Oil vs Pet Coke

Petroleum coke (pet coke) generally offers a lower cost per energy unit compared to traditional fuel oil, making it an economically attractive option for power generation and industrial heating. Fuel oil presents higher handling and storage costs due to its liquid state and environmental regulations, while pet coke requires specialized equipment to manage its solid, abrasive nature. Your choice between fuel oil and pet coke should consider not only raw fuel prices but also maintenance expenses, combustion efficiency, and emissions compliance costs to determine the most cost-effective solution.

Industrial Applications and Usage

Fuel oil is widely used in industrial boilers, power generation, and marine engines due to its high energy content and relatively cleaner combustion compared to pet coke. Pet coke, a carbon-rich byproduct of oil refining, is primarily utilized in cement kilns, power plants, and steel manufacturing where its high sulfur and carbon content can be effectively managed. Your choice between fuel oil and pet coke depends on specific industrial requirements, emission regulations, and cost factors.

Storage and Handling Differences

Fuel oil requires heating systems for storage to maintain fluidity, typically stored in insulated tanks to prevent solidification, while pet coke is stored as a solid bulk material in open yards with conveyors or silos. Handling fuel oil involves pumps and heated pipelines to manage viscosity, whereas pet coke demands heavy-duty equipment like front-end loaders and belt conveyors due to its abrasive and dusty nature. Safety precautions differ; fuel oil storage needs leak prevention and fire hazard controls, but pet coke storage requires dust suppression and handling measures to prevent respiratory and explosion risks.

Availability and Supply Chain

Fuel oil benefits from a well-established global supply chain with widespread availability due to its extensive refining processes and demand in various industries. Pet coke, a byproduct of crude oil refining, has a more limited and regional supply because its production is tied closely to specific refinery capacities and locations. Your choice between fuel oil and pet coke should consider the consistent availability and logistical ease that fuel oil offers compared to the more variable supply of pet coke.

Regulatory and Compliance Issues

Fuel oil and pet coke face distinct regulatory and compliance challenges due to their differing environmental impacts and chemical compositions. Fuel oil, especially heavy fuel oil, is subject to stringent sulfur content limits under regulations such as IMO 2020 to reduce SOx emissions, while pet coke is often regulated for its high carbon and heavy metal content, leading to stricter controls on emissions like SOx, NOx, and particulate matter. Compliance with air quality standards and disposal regulations requires operators to invest in advanced emission control technologies and continuous monitoring to minimize environmental and health risks.

Future Trends in Fuel Alternatives

Fuel oil and pet coke face increasing competition from cleaner alternatives like natural gas, biofuels, and hydrogen as global regulations tighten on emissions. Advances in renewable energy technologies and stricter environmental policies drive a significant shift towards lower-carbon fuels, reducing the demand for high-sulfur pet coke. Investment in carbon capture and storage (CCS) and hybrid fuel systems highlight future trends aiming to balance energy needs with sustainability goals.

Fuel oil vs Pet coke Infographic

libmatt.com

libmatt.com