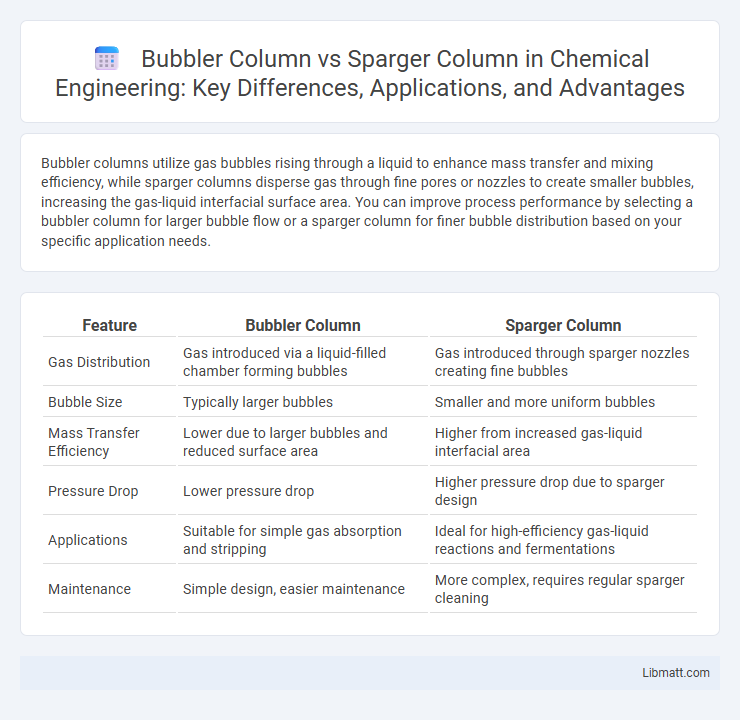

Bubbler columns utilize gas bubbles rising through a liquid to enhance mass transfer and mixing efficiency, while sparger columns disperse gas through fine pores or nozzles to create smaller bubbles, increasing the gas-liquid interfacial surface area. You can improve process performance by selecting a bubbler column for larger bubble flow or a sparger column for finer bubble distribution based on your specific application needs.

Table of Comparison

| Feature | Bubbler Column | Sparger Column |

|---|---|---|

| Gas Distribution | Gas introduced via a liquid-filled chamber forming bubbles | Gas introduced through sparger nozzles creating fine bubbles |

| Bubble Size | Typically larger bubbles | Smaller and more uniform bubbles |

| Mass Transfer Efficiency | Lower due to larger bubbles and reduced surface area | Higher from increased gas-liquid interfacial area |

| Pressure Drop | Lower pressure drop | Higher pressure drop due to sparger design |

| Applications | Suitable for simple gas absorption and stripping | Ideal for high-efficiency gas-liquid reactions and fermentations |

| Maintenance | Simple design, easier maintenance | More complex, requires regular sparger cleaning |

Introduction to Bubbler and Sparger Columns

Bubbler columns use gas bubbling through a liquid to enhance mass transfer efficiency, commonly applied in chemical reactors and fermentation processes. Sparger columns employ finely dispersed gas bubbles introduced via a sparger device, optimizing gas-liquid contact and improving reaction rates. Both columns are essential in process engineering for gas-liquid interactions but differ in bubble size distribution and fluid dynamics.

Fundamental Working Principles

A Bubbler column operates by injecting gas bubbles directly into the liquid phase through multiple small orifices, enhancing gas-liquid contact and mass transfer efficiency. A Sparger column, on the other hand, disperses gas more uniformly over a larger area, using a porous plate or tube to create fine bubbles that improve mixing and reaction rates. Your choice between the two depends on the specific application requirements, such as bubble size control and gas dispersion uniformity.

Design and Structure Differences

Bubbler columns feature a design with multiple small orifices or perforated plates allowing gas to form bubbles that rise through the liquid phase, enhancing surface area for mass transfer. Sparger columns employ a sparger device that introduces gas as fine bubbles or jets, often using porous materials or sintered metals, enabling better gas dispersion and more uniform bubble size. Your choice depends on specific process requirements, with bubblers favoring simpler construction and spargers providing superior gas distribution efficiency.

Gas-Liquid Mass Transfer Efficiency

Bubbler columns exhibit higher gas-liquid mass transfer efficiency due to their ability to create fine bubbles that increase the interfacial area, enhancing gas absorption rates. Sparger columns, while effective in distributing gas evenly, generally produce larger bubbles leading to lower mass transfer coefficients. The improved turbulence and mixing in bubbler columns maximize contact time, optimizing oxygen or other gas dissolution in liquid media.

Operational Flexibility and Scale-up

Bubbler columns offer enhanced operational flexibility due to their ability to handle varying gas flow rates and liquid volumes without significant performance loss, making them suitable for processes requiring frequent adjustments. Sparger columns, while effective for precise gas dispersion, may face scale-up challenges due to limited adaptability in gas-liquid contact areas and sensitivity to flow rate changes. When scaling up, your choice between a bubbler and sparger column should consider the process dynamics and operational demands to ensure efficient mass transfer and process control.

Applications in Industry

Bubbler columns excel in chemical processing industries such as gas absorption and distillation due to their efficient gas-liquid contact and ease of design for low-pressure operations. Sparger columns are widely applied in wastewater treatment and fermentation, providing superior gas dispersion for enhanced mass transfer and biological reaction rates. Your choice depends on the specific industrial application requirements, including gas flow rates and liquid properties.

Energy Consumption and Operational Costs

Bubbler columns typically consume less energy than sparger columns because they rely on lower gas flow rates and reduced pressure requirements, leading to decreased operational costs. Sparger columns require higher energy input to maintain fine bubble dispersion and uniform gas distribution, which increases power consumption and maintenance expenses. Optimizing your system choice based on energy consumption can significantly impact overall operational efficiency and cost savings.

Maintenance and Durability

Bubbler columns typically require less maintenance due to their simpler design and fewer moving parts, leading to enhanced durability in long-term operations. Sparger columns, while providing more precise gas dispersion, often demand regular inspection and cleaning to prevent clogging and wear, impacting their maintenance schedule. Your choice should consider the trade-off between the robust, low-maintenance nature of bubbler columns and the operational precision of sparger columns.

Advantages and Limitations

Bubbler columns offer superior gas-liquid mass transfer due to their high gas holdup and intense mixing, which enhances reaction rates in applications like fermentation and chemical synthesis. However, they face limitations such as increased pressure drop and potential fouling, which can reduce operational efficiency. Sparger columns provide uniform gas distribution and lower energy consumption but may exhibit lower gas holdup and reduced mass transfer efficiency compared to bubbler columns.

Choosing the Right Column for Your Process

Selecting between a bubbler column and a sparger column depends on factors such as gas-liquid contact efficiency and bubble size distribution. Bubbler columns typically generate larger bubbles, favoring processes requiring lower mass transfer rates, while sparger columns produce finer bubbles that enhance mass transfer and mixing efficiency. Evaluating the specific requirements of your process, including reaction kinetics and gas dispersion needs, will guide the optimal choice for maximizing performance and cost-effectiveness.

Bubbler column vs sparger column Infographic

libmatt.com

libmatt.com